تم شحن فرن الكربنة المستمرة SL-CF1200 بنجاح إلى المملكة المتحدة

في مارس 2025، تواصلت معنا شركة مقرها المملكة المتحدة تركز على استعادة الطبيعة وإدارة الكربون. كانوا بحاجة إلى فرن كربنة مستمر لدعم عملهم. قمنا بتزويدهم بنجاح بنموذج SL-CF1200.

خلفية العميل

فريق العميل مكرس لاستعادة الطبيعة ومواجهة تغير المناخ. تشمل أعمالهم الرئيسية استعادة الطبيعة ومشاريع إعادة التشجير، مع التركيز على إزالة الكربون. كانوا بحاجة إلى فرن بسعة 1000 كجم في الساعة.

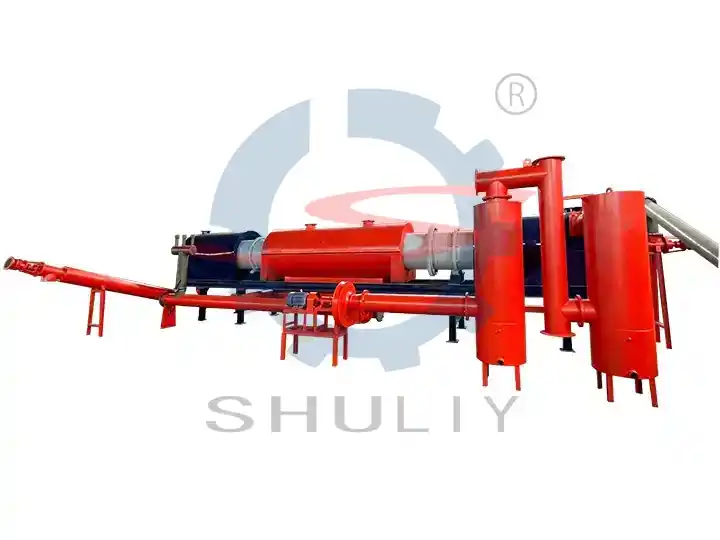

نموذج الفرن الموصى به والمواصفات

| نموذج | SL – CF1200 |

| القطر | 11.5*2*1.9م |

| وزن | 13طن |

| سعة | 1000كغ في الساعة |

| قوة | 25كيلووات |

| درجة الحرارة | 600 – 800℃ |

كيف يدعم فرن الكربنة المستمرة استعادة الطبيعة

انبعاثات الكربون السلبية

الفرن يحول النفايات الزراعية، وبقايا الغابات، والكتلة الحيوية إلى الفحم الحيوي. يمكن للفحم الحيوي تخزين الكربون لمئات إلى آلاف السنين، مما يزيل CO₂ من الغلاف الجوي بشكل دائم.

استبدال الوقود الأحفوري وتقليل الكربون

تقوم عملية الكربنة بإعادة تدوير الطاقة الحرارية، والتي يمكن استخدامها في التدفئة الصناعية أو توليد الطاقة، مما يقلل الاعتماد على الوقود الأحفوري ويخفض انبعاثات الكربون.

تحسين التربة

الفحم الحيوي يعمل كمعالج للتربة. إنه يعزز المادة العضوية، والاحتفاظ بالمياه، وتوافر العناصر الغذائية ويعزز نمو الميكروبات. إنه فعال بشكل خاص في استعادة التربة المتدهورة أو الحمضية أو المتصحرة.

إصلاح التربة الملوثة

بفضل قدرته العالية على الامتصاص، يقوم الفحم الحيوي بالتقاط المعادن الثقيلة والمبيدات الحشرية والملوثات العضوية، مما يساعد في تنظيف الأراضي الملوثة.

استعادة وحماية المياه

يمكن استخدام الفحم الحيوي في أنظمة تنقية المياه لامتصاص الملوثات وتحسين جودة المياه، مما يساعد في استعادة الأراضي الرطبة والبحيرات.

القيمة البيئية والاقتصادية لفرن الكربنة المستمرة

- الفوائد البيئية: تخزين الكربون، تحسين التربة، وتنقية المياه تدعم استعادة النظام البيئي.

- الفوائد الاقتصادية: يحول النفايات إلى فحم حيوي قيم مع طلب متزايد في الزراعة وحماية البيئة والبناء.

- نموذج الاقتصاد الدائري: من النفايات → الطاقة / الفحم الحيوي → استعادة الطبيعة → تحسين الإنتاجية الزراعية.

مزايا فرن الكربنة المستمر من شولي.

- أنظمة متوافقة: يمكن أن يعمل مع الكسارات، المجففات، آلات ضغط نشارة الخشب، إلخ، لإنتاج فحم عالي الجودة - جميعها متاحة من مصنعنا.

- توفير الوقت: تغذية وتفريغ مستمر؛ لا حاجة للتشغيل على دفعات.

- مواد خام متعددة الاستخدامات: مناسب تقريبًا لجميع نفايات الزراعة والغابات، مثل نشارة الخشب، قش الأرز، قشور جوز الهند، قشور الفول السوداني، والقش. كما أنه قادر أيضًا على الكربنة مثل العلب، ورق القصدير، ورق الألمنيوم.

- جسم فرن موثوق: مصنوع من الفولاذ المقاوم للصدأ ومواد حرارية 100% من الداخل لزيادة المتانة.

- حرارة ذاتية الاكتفاء: لا يتطلب طاقة خارجية - يستخدم الحرارة الناتجة عن نفسه لتشغيل العملية بالكامل.

- إنتاجية عالية: الإنتاج من 1000-1200 كجم في الساعة، حسب الطراز.

- تصميم مدمج: موفر للمساحة وسهل التركيب.

- فحم عالي الجودة: محتوى الكربون يصل إلى 95%، مثالي لعدة تطبيقات.

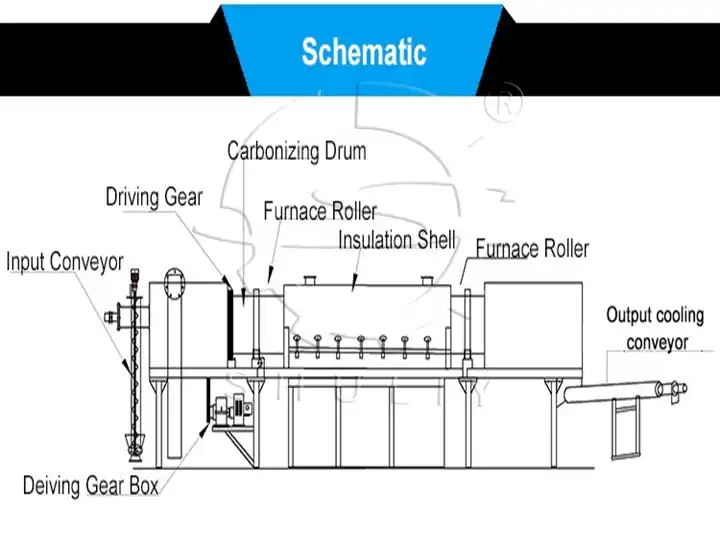

مخطط فرن الكربنة المستمرة

تعاون معنا

إذا كنت مهتمًا، يرجى الاتصال بنا للحصول على التفاصيل عبر WhatsApp مباشرة: https://wa.me/+8619139761487