Làm thế nào để chọn máy ép than đúng?

Là một loại máy dùng để nén bột than, bột than củi và bột than sinh khối thành nhiên liệu hình que,máy ép than củi ngày càng trở nên phổ biến trên thị trường. Tuy nhiên, với rất nhiều loại và mẫu mã máy ép than củi có sẵn, làm thế nào bạn có thể chọn được loại phù hợp nhất với nhu cầu của mình?

Các loại máy ép than củi

Loại 1: Máy ép than củi trục vít

Đây là loại phổ biến nhất, có cấu trúc đơn giản và giá cả phải chăng. Nó có thể nén trực tiếp bột than hoặc bột than thành các viên nén có hình dạng khác nhau. Khuôn có thể thay thế, cho phép sản xuất linh hoạt.

Loại 2: Máy ép than củi thủy lực

Loại này tạo ra các viên than củi dày đặc và bền hơn. Nó phù hợp với người dùng có yêu cầu chất lượng cao hơn và thường có chi phí cao hơn.

Loại 3: Máy ép viên than

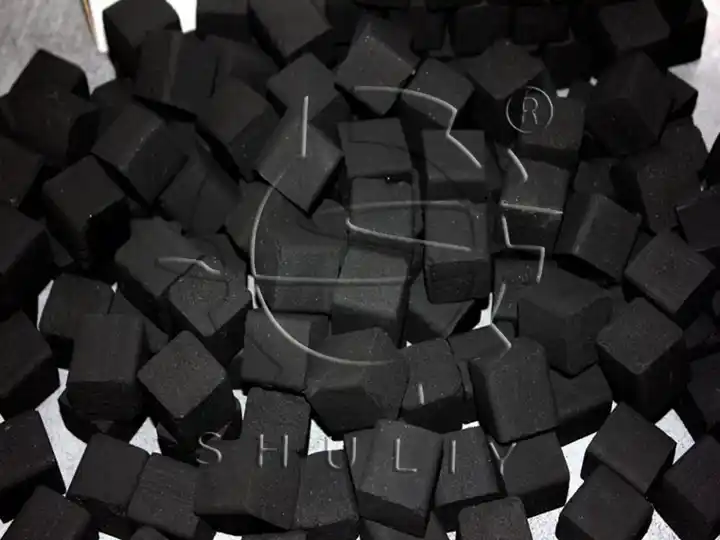

Ngoài nhiên liệu hình que, máy này còn có thể nén nguyên liệu thành các viên nén hình quả bóng, hình gối và các hình dạng khác.

Đánh giá loại nguyên liệu của bạn

Các loại nguyên liệu khác nhau có mức độ tương thích khác nhau với máy, vì vậy điều quan trọng là phải làm rõ các điểm sau trước khi mua hàng:

- Nguyên liệu của bạn là gì? Đó là bột than, bột than củi, than gáo dừa, than tre, v.v.?

- Nguyên liệu đã được nghiền và sấy khô chưa? Nó có cần thêm chất kết dính không?

- Độ ẩm có nằm trong phạm vi phù hợp không? (Thông thường được khuyến nghị từ 8%–12%)

Chỉ bằng cách hiểu rõ loại và tình trạng nguyên liệu của bạn, nhà sản xuất mới có thể đề xuất áp suất ép, cấu trúc khuôn và thiết bị phụ trợ phù hợp như máy nghiền hoặc máy trộn.

Xác định yêu cầu sản lượng của bạn

Khi chọn máy ép than củi, điều quan trọng là phải làm rõ các câu hỏi sau:

- Bạn dự định sản xuất bao nhiêu kg hoặc tấn than củi mỗi giờ hoặc mỗi ngày?

- Máy sẽ được sử dụng cho mục đích cá nhân hay sản xuất thương mại?

- Bạn có dự định mở rộng công suất sản xuất trong tương lai không?

Xem xét hình dạng sản phẩm cuối cùng và các tùy chọn khuôn

Các thị trường khác nhau có yêu cầu khác nhau về hình thức của than củi. Ví dụ:

- Than cho BBQ: Thường có hình lục giác với lỗ ở giữa. Thiết kế rỗng giúp đánh lửa và lưu thông không khí.

- Than để sưởi ấm: Ưu tiên các thanh tròn đặc, vì chúng cháy lâu hơn.

- Than cho Nhiên liệu Công nghiệp: Thường yêu cầu các viên nén có đường kính lớn hơn và mật độ cao hơn.

Khi chọn máy, hãy đảm bảo rằng nó hỗ trợ thay thế khuôn và cho phép tùy chỉnh kích thước và hình dạng theo nhu cầu cụ thể của bạn.

Cấu hình nguồn và tiêu thụ năng lượng

- Truyền động bằng động cơ điện: Phù hợp với những khu vực có nguồn điện ổn định. Nó có độ ồn thấp và chi phí vận hành thấp.

- Truyền động bằng động cơ Diesel: Lý tưởng cho những địa điểm không có điện hoặc nơi nguồn điện bị hạn chế, chẳng hạn như các khu vực nông thôn hoặc miền núi.

- Truyền động PTO (Sử dụng Nguồn từ Máy kéo): Một lựa chọn linh hoạt cho người dùng nông nghiệp thích sử dụng thiết bị nông nghiệp hiện có.

Ngoài ra, hãy đảm bảo cấu hình nguồn của máy phù hợp với điện áp và tiêu chuẩn điện của địa phương bạn.

Dịch vụ hậu mãi và độ tin cậy của nhà sản xuất

Khi chọn máy ép than củi, điều quan trọng là phải xem xét sức mạnh của nhà sản xuất và hỗ trợ sau bán hàng. Hãy chú ý đến những điều sau:

- Nhà sản xuất có cung cấp dịch vụ lắp đặt, vận hành thử và đào tạo không?

- Có sẵn hướng dẫn vận hành và video hướng dẫn không?

- Các bộ phận hao mòn có dễ thay thế không và có đủ nguồn cung cấp phụ tùng không?

- Nhà sản xuất có kinh nghiệm xuất khẩu không? Họ có thể hỗ trợ thủ tục hải quan và cung cấp các chứng chỉ cần thiết không?

Shuliy là nhà cung cấp máy than củi với 14 năm kinh nghiệm sản xuất và khả năng xuất khẩu mạnh mẽ. Chúng tôi không chỉ cung cấp dịch vụ lắp đặt, vận hành và đào tạo mà còn cung cấp sách hướng dẫn vận hành và video hướng dẫn miễn phí.

Tất cả các sản phẩm của chúng tôi đều đi kèm với bảo hành một năm, đảm bảo trải nghiệm sau bán hàng đáng tin cậy và không lo lắng.

Các mẫu máy ép than củi Shuliy được đề xuất

Shuliy cung cấp nhiều mẫu máy ép than khác nhau để đáp ứng nhu cầu sản xuất khác nhau. Dưới đây là các mẫu bán chạy nhất của chúng tôi:

Mẫu: SL-CB160

Công suất: 500kg/h

Công suất: 11kw

Kích thước: 2050*900*1250mm

Trọng lượng: 900kg

Điện áp: Hỗ trợ tùy chỉnh

Ngày sản xuất: 15~20 ngày làm việc

Vận chuyển: Bằng đường biển hoặc đường hàng không

Điện áp nguồn và loại phích cắm có thể được tùy chỉnh theo yêu cầu của bạn. Vui lòng liên hệ với chúng tôi để biết thêm thông tin.

Tóm tắt mua hàng

Việc chọn máy ép than củi không khó nếu bạn tập trung vào các điểm chính sau:

- Xác nhận loại và tình trạng nguyên liệu thô của bạn

- Xác định rõ yêu cầu về công suất sản xuất của bạn

- Hiểu thông số kỹ thuật và hình dạng của than củi thành phẩm

- Kết hợp cấu hình nguồn phù hợp

- Chọn nhà sản xuất có dịch vụ toàn diện và kinh nghiệm phong phú

Ưu đãi của Shuliy

- Kiểu vít máy làm than bánhcó nhiều mẫu mã khác nhau để đáp ứng nhu cầu công suất sản xuất khác nhau của bạn, tất cả với mức giá phải chăng.

- Dịch vụ khuôn tùy chỉnh hỗ trợ nhiều kích cỡ và hình dạng viên than củi.

- Giải pháp dây chuyền sản xuất hoàn chỉnh, bao gồm dây chuyền than củi BBQ, dây chuyền sản xuất than củi, dây chuyền than củi shisha, và nhiều hơn nữa.

- Tư vấn trước bán hàng chuyên nghiệp và hỗ trợ sau bán hàng.

- Bảo hành 12 tháng cho tất cả các sản phẩm.

- Dịch vụ vận chuyển một cửa để giao hàng thuận tiện.

Chúng tôi nhiệt liệt chào mừng bạn liên hệ với chúng tôi để được tư vấn thêm và thảo luận sâu hơn.