مكبس الخشب الشامل | مفرمة منصات الخشب

كسارة البليت الخشبية

مكبس الخشب الشامل | مفرمة منصات الخشب

كسارة البليت الخشبية

الميزات في لمحة

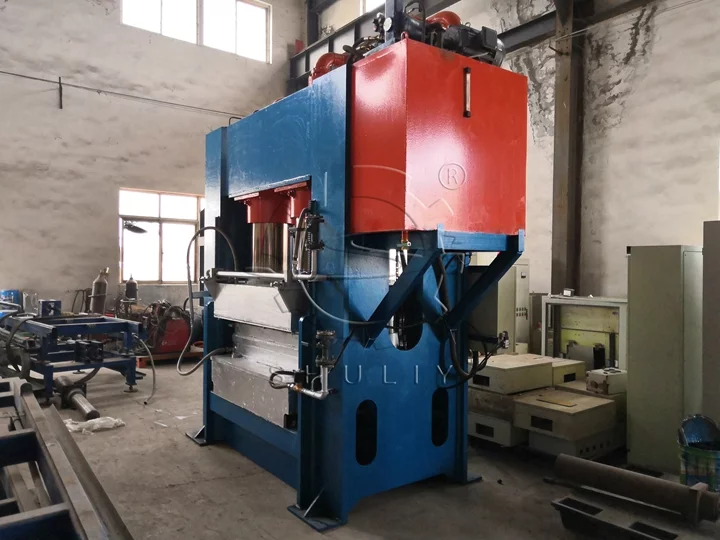

الكسارة الشاملة للخشب، والمعروفة عادةً باسم مفرمة المنصات الخشبية، هي آلة معالجة خشب أولية كبيرة ومتوسطة الحجم. مصممة لطحن المنصات الخشبية، والأخشاب، والفروع، والخيزران، والقوالب الإنشائية، والدعائم، والألواح التي تحتوي على مسامير، وجذور الأشجار، والأعشاب، والأثاث المهمل إلى رقائق خشبية أصغر من 100 ملم. يمكن أن تصل سعة الإنتاج إلى 8-30 طن في الساعة.

يمكن مطابقة المعدات مع أنظمة ناقل بأطوال مختلفة، مما يوفر مجموعة واسعة من التطبيقات. كما يمكن تجهيزها بـ أسطوانة مغناطيسية لإزالة المسامير والشوائب المعدنية الأخرى تمامًا من رقائق الخشب، لضمان خلو المنتج النهائي من المعادن. لذلك، فإن هذه الآلة مناسبة بشكل خاص لصناعات مثل إعادة تدوير الخشب، وطحن المنصات الخشبية، وتفتيت الأثاث المهمل.

إن تعدد استخداماته في التعامل مع المواد الخشبية المختلفة، إلى جانب قدرته على إدارة النفايات الخشبية الكبيرة بكفاءة، جعل منه الحل المفضل بين الصناعات في جميع أنحاء العالم، بما في ذلك كندا وماليزيا والبرازيل.

ما هي المواد التي يمكن لآلة تقطيع البليت الخشبية معالجتها؟

إن آلة تقطيع الباليتات الخشبية عبارة عن آلة متعددة الاستخدامات تم تصميمها لمعالجة مجموعة واسعة من المواد الخشبية بكفاءة، مما يجعلها أداة أساسية في عمليات إدارة النفايات وإعادة التدوير.

المواد التي يمكن معالجتها:

- المخلفات الزراعية والقش: مثل سيقان المحاصيل، قش الأرز، قش الحبوب، والمواد المتبقية الناتجة أثناء التعامل مع المنتجات الزراعية أو معالجتها.

- نفايات الغابات والأخشاب: بما في ذلك فروع الأشجار، الجذور، الأوراق، نشارة الخشب، رقائق الخشب، وغيرها من المنتجات الثانوية من عمليات القطع أو معالجة الأخشاب.

- المواد الخشبية المهملة والباليتات: مثل القوالب القديمة، ألواح البناء التي تحتوي على مسامير، الأثاث الخشبي المهمل، الباليتات، وإطارات الباليت بأحجام مختلفة.

- قدرات إضافية. يمكنها أيضًا معالجة الألواح الخشبية والألواح الخشبية والخردة من مواقع البناء أو التصنيع، وتستوعب تركيبات وأحجام خشبية مختلفة.

تجعل مرونة الكسارة الشاملة للخشب منها أصلًا قيمًا للشركات التي تتطلع إلى تحسين عمليات إدارة النفايات والمساهمة في جهود إعادة التدوير.

تطبيق الكسارة الشاملة للخشب

يتم استخدام آلة تقطيع البليت الخشبية على نطاق واسع في مختلف الصناعات التي تولد نفايات خشبية كبيرة. إنها أداة حاسمة لإدارة النفايات بكفاءة. تستفيد الصناعات مثل الخدمات اللوجستية والتخزين والتصنيع والبناء بشكل كبير من قدراتها.

تقوم آلة التقطيع بمعالجة مجموعة واسعة من المواد الخشبية بكفاءة، بما في ذلك المنصات الخشبية والصناديق ومواد التعبئة والتغليف وحتى القطع الخشبية الكبيرة.

- تطبيقات الصناعة. لا غنى عن آلة التقطيع في قطاعات مثل الخدمات اللوجستية والتخزين والبناء، حيث تتعامل مع كميات كبيرة من النفايات الخشبية، بما في ذلك المنصات والصناديق ومواد التعبئة الخشبية.

- معالجة متعددة الاستخدامات. فهو يقلل بشكل فعال القطع الكبيرة من الأخشاب والمواد الخشبية الأخرى إلى أحجام يمكن التحكم فيها، مما يحسن عمليات التخلص من النفايات وإعادة التدوير.

- الاستخدامات الثانوية. يمكن إعادة استخدام الخشب الممزق الذي تنتجه هذه الآلة بطرق مختلفة. ويمكن معالجته إلى وقود الكتلة الحيوية، أو استخدامه في إنتاج الألواح الحبيبية، أو تحويله إلى فراش للحيوانات، أو استخدامه كمواد خام للمواد المركبة، مما يساهم في الممارسات المستدامة.

من خلال دمج آلة تقطيع الألواح الخشبية في عملياتها، لا تقوم الشركات بتعزيز كفاءة إدارة النفايات فحسب، بل تساهم أيضًا في إنشاء منتجات ذات قيمة معاد تدويرها.

مواصفات الكسارة الشاملة للخشب

| نموذج | إس إل-1300 | إس إل-1400 | إس إل-1600 |

| حجم مدخل التغذية | 1300*500 مللي متر | 1400*800 ملم | 1600*800 مللي متر |

| تغذية الحد الأقصى للقطر | 400 ملم | 500 ملم | 600 ملم |

| حجم الإنتاج | أقل من 100 ملم | أقل من 100 ملم | أقل من 100 ملم |

| ناقل الإدخال | 6 م | 6 م | 6 م |

| ناقل الإخراج | 8 م | 10 م | 10 م |

| شفرات (قطعة) | 20 | 32 | 66 |

| سعة | 8-10 طن / ساعة | 10-15 طن/ساعة | 20-30 طن/ساعة |

| إجمالي الطاقة | 156.5 كيلو واط | 213.5 كيلو واط | 233.5 كيلو واط |

| الحجم الكلي | 8600*2000*2300 مللي متر | 9600*2400*3300 مللي متر | 12500*2800*3200 مللي متر |

أجهزتنا متوفرة بمواصفات مختلفة لتلبية الاحتياجات المتنوعة لمختلف الصناعات. قد تتضمن المواصفات معلمات مثل قوة المحرك وسعة التقطيع وحجم التغذية والأبعاد. من Shuliy، سوف تجد المنتج المناسب لعملك.

الميزات الرئيسية لآلة التكسير الشاملة للخشب

وهي مجهزة بالعديد من الميزات التي تساهم في تشغيلها بكفاءة وموثوقية. اختار العديد من العملاء آلتنا وحصلوا على أداء رائع.

تصميم بدون أساس لسهولة التركيب

تعتمد الآلة على هيكل بدون أساس، مما يسمح بالتركيب المباشر بدون قواعد خرسانية. مقارنةً بالكسارات التقليدية، يمكن تقليل وقت التركيب بنسبة 40٪، مما يوفر في العمالة وتكاليف البناء.

التحكم الذكي التلقائي بالكامل

مزودة بنظام تحكم تلقائي PLC، يتم أتمتة عملية التغذية، والطحن، والتفريغ بالكامل. هذا يقلل من مخاطر السلامة الناتجة عن التشغيل اليدوي ويحسن كفاءة التشغيل.

طحن عالي الكفاءة وتغذية سلسة

نظام التغذية المحسن المصمم بتصميم متعدد الشفرات يضمن تغذية سلسة للمادة دون انسداد.

- شفرات متعددة السبائك تحسن كفاءة التكسير بنسبة 20-30٪؛

- حجم إخراج موحد، الحد الأقصى ≤100 ملم، مناسب للتشكيل أو إنتاج الوقود.

توافق واسع للمواد

قادرة على معالجة الخيزران، والمنصات الخشبية، والألواح المطاطية، والأثاث المهمل، وأكثر من ذلك. حتى المنصات الخشبية المثبتة بمسامير يمكن سحقها مباشرة دون تفكيك. الشفرات متينة للغاية، وتمنع التلف الناتج عن الشوائب المعدنية.

نظام هيدروليكي للصيانة السهلة

تصميم الفتح الهيدروليكي لهيكل الآلة يسمح بفحص واستبدال الشفرة في بضع دقائق فقط، مما يحسن كفاءة الصيانة بنسبة 50% ويقلل من وقت التوقف.

نظام تفريغ قابل للتعديل

يمكن تعديل اتجاه التفريغ إلى اليسار أو اليمين أو الخلف وفقًا لتخطيط المصنع، مما يوفر عملية مرنة واستخدامًا مثاليًا للمساحة.

هيكل متين ومواد مقاومة للتآكل

جسم الآلة مصنوع من فولاذ كربوني سميك ملحوم، مع أقراص شفرات وعمود رئيسي مقاوم للحرارة العالية لضمان استقرار التشغيل تحت الأحمال الثقيلة. يمكن أن تصل مدة الخدمة إلى أكثر من 10 سنوات.

نظام مراقبة مدمج للسلامة

شاشات مراقبة مدمجة تعرض المعلمات الرئيسية مثل السرعة، والتيار، ودرجة الحرارة في الوقت الحقيقي. التحذيرات المبكرة تمنع الأعطال، وتضمن تشغيلًا آمنًا ومستمرًا.

هيكل الآلة

تتكون الكسارة الشاملة للخشب من حزام ناقل، مناشير التكسير (نوع الشفرة للخشب الخالي من المسامير ونوع المخلب للمواد المثبتة بمسامير)، بكرات الضغط، نظام تصفية، وحزام تفريغ.

كيف تعمل كسارة البليت الخشبية؟

تعمل كسارة الباليتات الخشبية بشكل أساسي من خلال استخدام طاقة الصدم لتكسير المواد الخشبية بشكل فعال. وإليك كيف يعمل.

- دوران عالي السرعة. محرك الكسارة يدفع الدوار للدوران بسرعة عالية. عندما يدخل الخشب إلى غرفة التكسير، فإنه يواجه رأس المطرقة الذي يدور بسرعة.

- سحق التأثير. يتحرك رأس المطرقة بسرعة عالية ويضرب الخشب بقوة كبيرة. هذا التأثير هو الآلية الأساسية التي تتسبب في تفكك الخشب.

- مساعدة الجاذبية. بالإضافة إلى تأثير رأس المطرقة، يساهم وزن الخشب نفسه في عملية التكسير. يضمن هذا الجمع تفكيك المادة بشكل شامل.

- عملية الفرز. يتم بعد ذلك تمرير الخشب المسحوق من خلال شاشة موجودة في الجزء السفلي من الكسارة. يتم تفريغ القطع الخشبية الأصغر من حجم الشاشة، بينما تبقى القطع الأكبر حجمًا بالداخل.

- استمرار السحق. تستمر قطع الخشب الأكبر حجمًا التي لا تمر عبر الشاشة في الضرب والأرض بواسطة المطارق حتى تصل إلى الحجم المناسب ويمكن أن تمر عبر الشاشة للتفريغ.

لماذا تختار شراء كسارة الخشب الشاملة لدينا؟

يعد اختيار مورد موثوق وذو سمعة طيبة أمرًا ضروريًا لإدارة نفايات الخشب بشكل فعال. توفر كسارات الخشب الشاملة لدينا العديد من المزايا التي تميزها عن المنافسة.

- المتانة والكفاءة. تم تصميم كساراتنا لتدوم طويلاً، وتتميز ببنية قوية تضمن الأداء والموثوقية على المدى الطويل. وهي مصممة للتشغيل الفعال، وتقليل وقت التوقف عن العمل وتكاليف الصيانة.

- مجموعة واسعة من النماذج. نحن نقدم مجموعة متنوعة من النماذج لتلبية احتياجات العملاء المختلفة. سواء كنت تحتاج إلى آلة للعمليات صغيرة الحجم أو العمليات الصناعية الكبيرة، فلدينا حل مصمم خصيصًا لتلبية متطلباتك.

- التكنولوجيا المتقدمة. مجهزة بأحدث التقنيات، تتعامل كسارات الخشب لدينا مع مجموعة واسعة من المواد الخشبية، بدءًا من المنصات وحتى الأخشاب الكبيرة، مما يوفر التنوع والكفاءة في معالجة نفايات الخشب.

- دعم عملاء ممتاز. يقدم فريق الخبراء المتخصص لدينا خدمة عملاء استثنائية، ويساعدك في اختيار الماكينة المناسبة وتوفير الدعم المستمر لضمان الأداء الأمثل.

اختيار كسارات الخشب الشاملة لدينا يعني الاستثمار في آلات عالية الجودة مدعومة بدعم خبير. اتصل بنا اليوم للحصول على الأسعار واستكشاف كيف يمكن أن تحسن حلولنا من عمليات إدارة نفايات الخشب لديك.

آلة طحن الخشب | آلة تكسير الخشب الصناعية

تم تصميم آلات تكسير الخشب لمعالجة أنواع مختلفة من الخشب بكفاءة...

مطحنة المطرقة الخشبية | آلة تكسير المطرقة

مطحنة الخشب المطرقة تعتمد على نظام المطرقة والشاشة…

آلة تقشير الخشب | تقشير جذوع الأشجار لفرش الحيوانات

آلة تقشير الخشب يمكنها قطع الأخشاب، الفروع، و…

آلة تقطيع الخشب الدوارة | آلة صنع رقائق الخشب

مقصات الخشب المصنوعة من الأقراص مصممة للتعامل مع مجموعة واسعة…

آلة تقشير الخشب | آلة تقشير جذوع الأشجار

تُعرف آلة نزع لحاء الخشب أيضًا باسم آلة تقشير الجذوع...

آلة تصنيع حبيبات علف الحيوانات | مطحنة حبيبات العلف

تقدم شركة Shuliy آلة تصنيع أعلاف الحيوانات للبيع. يمكنك...

آلة منشرة الخشب المحمولة | آلة قطع الأخشاب

تجمع آلة منشار الخشب المحمولة من شركة Shuliy Machinery بين...

منتج رائج

آلة صنع كتل الألواح الخشبية

تستخدم آلة صنع كتل منصات الخشب نشارة الخشب و…

آلة تقشير الخشب | تقشير جذوع الأشجار لفرش الحيوانات

تقوم آلة نشارة الخشب بتقطيع ومعالجة الأخشاب بكفاءة...

كسارة الخشب الشاملة | مفرمة الألواح الخشبية

المطحنة الشاملة، المعروفة عادةً باسم…

فرن الكربنة المستمر | آلة صنع فحم الخشب من نشارة الخشب

فرن الكربنة المستمر مخصص للعمليات واسعة النطاق…

آلة ضغط فحم الخشب | آلة ضغط فحم الخشب

آلة قرميد الفحم النباتي، المعروفة أيضًا بـ…

آلة تجفيف قش الأرز | مجفف دوار للبيع

آلة تجفيف قشر الأرز لدينا، أو جهاز دوار…

مطحنة المطرقة الخشبية | آلة تكسير المطرقة

مطحنة الخشب بالمطرقة تسحق رقائق الخشب بكفاءة،…

آلة تجفيف مكعبات الفحم المعبأة في علب

آلة تجفيف قوالب الفحم الصندوقية هذه هي…

آلة منشرة الخشب المحمولة | آلة قطع الأخشاب

تتمتع ماكينة منشار أخشاب متنقلة بقدرات رائعة…