Concasseur complet | Broyeur de palettes en bois

Broyeur de palettes en bois

Concasseur complet | Broyeur de palettes en bois

Broyeur de palettes en bois

Aperçu des fonctionnalités

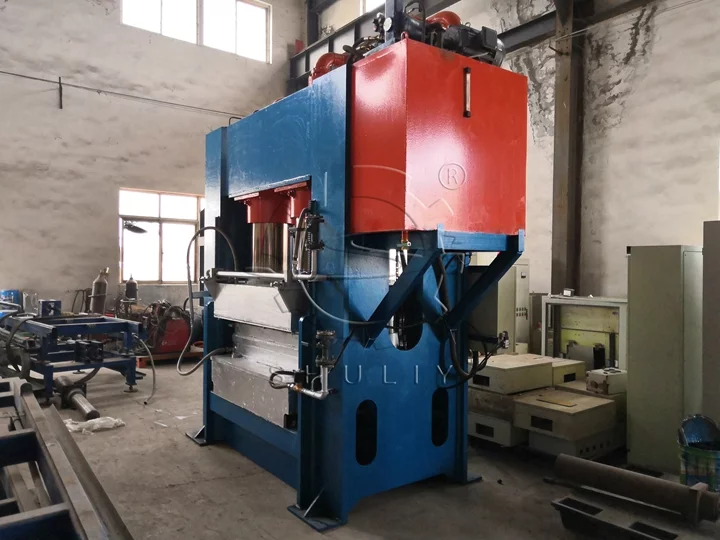

Le broyeur complet, communément appelé broyeur de palettes en bois, est conçu pour transformer les palettes en bois, les meubles et les coffrages de construction (même ceux avec des clous) en copeaux de bois irréguliers, avec une capacité robuste de 8 à 30 t/h.

Sa polyvalence dans la manipulation de divers matériaux en bois, associée à sa capacité à gérer efficacement les déchets de bois massifs, en a fait une solution privilégiée parmi les industries du monde entier, notamment au Canada, en Malaisie et au Brésil.

Quels matériaux le broyeur de palettes en bois peut-il traiter ?

Le broyeur de palettes en bois est une machine très polyvalente conçue pour traiter efficacement une large gamme de matériaux à base de bois, ce qui en fait un outil essentiel dans les opérations de gestion des déchets et de recyclage.

- Matières premières. Ce broyeur est conçu pour traiter divers types de déchets de bois, notamment les palettes en bois, les meubles, les portes, les fenêtres et les gabarits de construction, même ceux incrustés de clous ou d'autres attaches.

- Capacités supplémentaires. Elle peut également traiter des planches et des chutes de bois provenant de chantiers de construction ou de fabrication, s'adaptant à différentes compositions et tailles de bois.

L'adaptabilité du broyeur de palettes en bois en fait un atout précieux pour les entreprises qui cherchent à optimiser leurs processus de gestion des déchets et à contribuer aux efforts de recyclage.

Application du broyeur de palettes en bois

Le broyeur de palettes en bois est largement utilisé dans diverses industries qui génèrent d’importants déchets de bois. Il s’agit d’un outil crucial pour une gestion efficace des déchets. Des secteurs tels que la logistique, l’entreposage, la fabrication et la construction bénéficient grandement de ses capacités.

Le broyeur traite efficacement une large gamme de matériaux en bois, notamment des palettes en bois, des caisses, des matériaux d'emballage et même de gros morceaux de bois.

- Applications industrielles. Le broyeur est indispensable dans des secteurs comme la logistique, l'entreposage et la construction, où il traite de grands volumes de déchets de bois, notamment des palettes, des caisses et des matériaux d'emballage en bois.

- Traitement polyvalent. Il réduit efficacement les gros morceaux de bois et autres matériaux en bois à des tailles gérables, optimisant ainsi les processus d'élimination et de recyclage des déchets.

- Utilisations secondaires. Le bois déchiqueté produit par cette machine peut être réutilisé de différentes manières. Il peut être transformé en combustible biomasse, utilisé dans la production de panneaux de particules, transformé en litière pour animaux ou servir de matière première pour des matériaux composites, contribuant ainsi à des pratiques durables.

En intégrant le broyeur de palettes en bois dans leurs opérations, les entreprises améliorent non seulement l'efficacité de leur gestion des déchets, mais contribuent également à la création de produits recyclés de valeur.

Spécifications du concasseur complet

| Modèle | SL-1300 | SL-1400 | SL-1600 |

| Taille de l'entrée d'alimentation | 1300*500mm | 1400*800mm | 1600*800mm |

| Diamètre maximum d'alimentation | 400mm | 500 mm | 600mm |

| Taille de sortie | Moins de 100 mm | Moins de 100 mm | Moins de 100 mm |

| Convoyeur d'entrée | 6m | 6m | 6m |

| Convoyeur de sortie | 8m | 10m | 10m |

| Lames (pièces) | 20 | 32 | 66 |

| Capacité | 8-10 t/h | 10-15t/heure | 20-30t/heure |

| Pouvoir total | 156,5 kW | 213,5 kW | 233,5 kW |

| Taille globale | 8600*2000*2300mm | 9600*2400*3300mm | 12500*2800*3200mm |

Nos machines sont disponibles dans diverses spécifications pour répondre aux divers besoins de différentes industries. Les spécifications peuvent inclure des paramètres tels que la puissance du moteur, la capacité de déchiquetage, la taille de l'alimentation et les dimensions. Chez Shuliy, vous trouverez celui qui convient à votre entreprise.

Principales caractéristiques du concasseur complet

Il est doté de plusieurs fonctionnalités qui contribuent à son fonctionnement efficace et fiable. De nombreux clients ont choisi notre machine et ont obtenu d'excellentes performances.

- Conception sans fondation. Simplifie l'installation en éliminant le besoin de fondations, ce qui permet d'économiser du temps, de la main-d'œuvre et des ressources.

- Contrôle entièrement automatique. Automatise les processus d'alimentation et de déchargement, améliorant ainsi la capacité de production et garantissant un environnement d'exploitation sûr.

- Manutention efficace des matériaux. Gère divers matériaux, notamment le bambou, les planches en caoutchouc et les palettes de marchandises, sans les endommager par des clous ou d'autres obstructions.

- Mécanisme d'alimentation en douceur. Augmente la capacité de production en assurant une alimentation en matériaux plus fluide et plus efficace.

- Durée de vie prolongée. Construit pour la durabilité avec des exigences d'entretien minimales, réduisant ainsi les coûts globaux de maintenance.

- Système de décharge secondaire. Permet un fonctionnement flexible en permettant aux utilisateurs d'ajuster la direction de décharge selon les besoins.

- Système hydraulique. Comprend un mécanisme hydraulique d'ouverture et de fermeture du boîtier, simplifiant les procédures de maintenance.

- Système de surveillance intégré. Fournit une surveillance en temps réel de l’état opérationnel, garantissant des performances sûres et fiables de la machine.

Comment fonctionne le broyeur de palettes en bois ?

Le broyeur de palettes en bois fonctionne principalement grâce à l’utilisation de l’énergie d’impact pour décomposer efficacement les matériaux en bois. Voici comment cela fonctionne.

- Rotation à grande vitesse. Le moteur du concasseur entraîne le rotor à tourner à grande vitesse. Lorsque le bois entre dans la chambre de concassage, il rencontre le marteau qui tourne rapidement.

- Concassage par impact. Le marteau, se déplaçant à grande vitesse, frappe le bois avec une force importante. Cet impact est le principal mécanisme qui provoque la rupture du bois.

- Assistance gravitationnelle. Outre l’impact du marteau, le poids du bois lui-même contribue au processus de broyage. Cette combinaison garantit une décomposition complète des matériaux.

- Processus de sélection. Le bois broyé passe ensuite à travers un tamis situé au bas du broyeur. Les morceaux de bois plus petits que la taille du tamis sont évacués, tandis que les morceaux plus gros restent à l'intérieur.

- Écrasement continu. Les morceaux de bois plus gros qui ne traversent pas le tamis continuent d'être frappés et broyés par les marteaux jusqu'à ce qu'ils atteignent la taille appropriée et puissent passer à travers le tamis pour être déchargés.

Pourquoi choisir d'acheter notre broyeur de bois complet ?

La sélection d’un fournisseur fiable et réputé est essentielle pour une gestion efficace des déchets de bois. Nos broyeurs de bois complets offrent plusieurs avantages qui les distinguent de la concurrence.

- Durabilité et efficacité. Nos concasseurs sont conçus pour durer, avec une construction robuste qui garantit des performances et une fiabilité à long terme. Ils sont conçus pour un fonctionnement efficace, réduisant les temps d'arrêt et les coûts de maintenance.

- Large gamme de modèles. Nous proposons une sélection diversifiée de modèles pour répondre aux différents besoins des clients. Que vous ayez besoin d'une machine pour des opérations à petite échelle ou pour de grands processus industriels, nous avons une solution adaptée à vos besoins.

- Technologie avancée. Équipés d'une technologie de pointe, nos broyeurs de bois traitent une large gamme de matériaux en bois, des palettes aux gros bois, offrant polyvalence et efficacité dans le traitement des déchets de bois.

- Excellent support client. Notre équipe d'experts dévoués offre un service client exceptionnel, vous aidant à sélectionner la bonne machine et vous fournissant une assistance continue pour garantir des performances optimales.

Choisir notre gamme complète bois concasseurs signifie investir dans des machines de haute qualité soutenues par un support expert. Contactez-nous dès aujourd'hui pour connaître les tarifs et découvrir comment nos solutions peuvent améliorer vos processus de gestion des déchets de bois.

Machine à copeaux de bois | Copeaux de bûches pour litière pour animaux

La machine à copeaux de bois coupe et traite efficacement le bois pour…

Broyeur à marteaux en bois | Broyeur à marteaux

Le broyeur à marteaux à bois broie efficacement les copeaux de bois, la paille, les déchets…

Machine de broyeur de bois | Broyeur de bois industriel

Les broyeurs de bois sont conçus pour traiter efficacement divers bois…

Déchiqueteuse à bois à disque | Machine de fabrication de copeaux de bois

La déchiqueteuse à bois à disque constitue une solution polyvalente pour le traitement…

Machine de fabrication de blocs de palettes en bois

La machine de fabrication de blocs de palettes en bois utilise de la sciure de bois et divers autres…

Machine à écorcher le bois | Machine à éplucher les bûches

Machine à écorcher le bois, également connue sous le nom de machine à éplucher les bûches,…

Machine à granulés d'alimentation animale | Machine de broyeur d'aliments pour granulés

Shuliy propose à la vente la machine à granulés d'aliments pour animaux. Toi…

Machine portative de scierie à bois | Machine à scier le bois

La scierie à bois portable de Shuliy Machinery combine…

Machine de fabrication de palettes en bois au Sénégal

En tant que fournisseur de la machine de fabrication de palettes en bois, nous…

Broyeur de bois pour entreprises envoyé en Pologne

Nous sommes heureux de présenter une étude de cas réussie impliquant…

Produit chaud

Machine à copeaux de bois | Copeaux de bûches pour litière pour animaux

La machine à copeaux de bois coupe et traite efficacement…

Déchiqueteuse à bois à tambour

Une déchiqueteuse à bois à tambour est utilisée dans…

Four de carbonisation vertical pour la fabrication de charbon de bois dur

Ce four de carbonisation vertical peut être utilisé pour…

Machine à palettes en bois comprimé pour palettes en bois pressé

Notre machine à palettes en bois compressé est conçue pour…

Four de carbonisation continue | Machine de fabrication de charbon de bois de sciure de bois

La fournaise de carbonisation continue est pour la grande échelle…

Machine de fabrication de blocs de palettes en bois

La machine de fabrication de blocs de palettes en bois utilise de la sciure de bois et…

Machine à granulés d'alimentation animale | Machine de broyeur d'aliments pour granulés

Shuliy propose la machine à granulés d'aliments pour animaux pour…

Broyeur à marteaux en bois | Broyeur à marteaux

Le broyeur à marteaux en bois broie efficacement les copeaux de bois,…

Machine à charbon de chicha pour charbon de narguilé rond et cubique

Notre populaire machine à charbon de chicha peut produire des produits de haute qualité…