特点一览

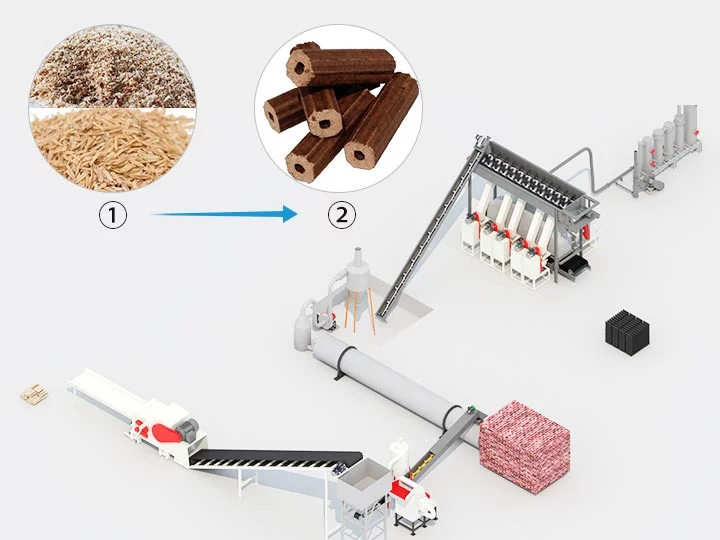

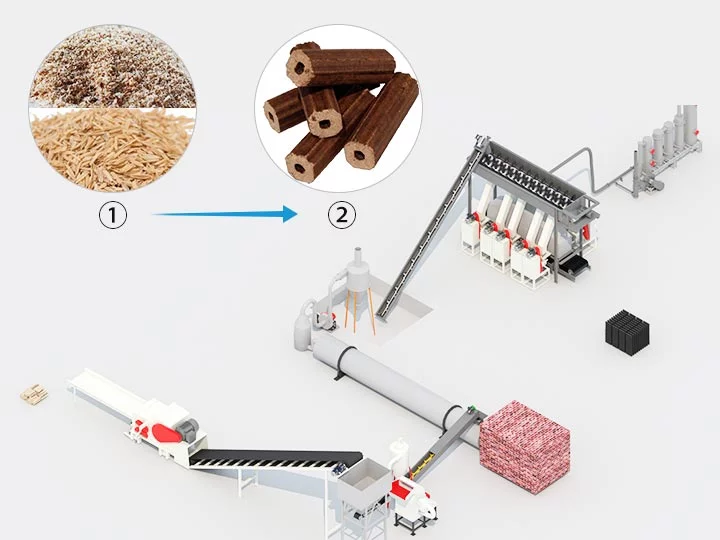

这 木屑压块生产线,也称为松木加工厂,用于将锯末和其他原料转化为生物质燃料,称为松木热块。该生产线的主要设备包括 木材破碎机、木材粉碎机、旋转式干燥机、锯末压块机和螺旋输送机。 您可以高效生产环保且广泛用于取暖和烹饪的松木压块。联系我们获取优惠价格。

该木屑压块生产线的产能主要由锯末压块机的数量决定。每台压块机的生产能力为250公斤/小时。该生产线的最常见配置为每小时1吨。

无论所需产量如何,Shuliy都可以根据您的需求定制和配置生产线。欢迎通过右侧的在线聊天窗口联系我们获取更多详情。

木屑成型生产线的应用

木屑压块生产线的应用对于生产高品质生物质燃料(称为“pini kay 热原木”)至关重要。该工业生产线通过在高温高压下挤压锯末或稻壳来有效地加工它们。

通过该工艺生产的 Pini kay 热原木在各个行业和领域都有广泛的应用。它们是煤炭和木炭等传统燃料的环保且可持续的替代品。这些煤球广泛用于加热、烹饪和发电目的。住宅家庭、商业机构和工业设施都可以受益于皮尼凯加工厂提供的清洁高效的能源。

生产木屑煤球的原料

除了常见的原料如原木、硬木和树枝(如松树和橡木)外,压块生产线还可以处理各种生物质材料。

木质材料

- 原木和硬木

- 树枝和木料边角料

- 锯末和木屑

农业残渣

- 棉花秆

- 高粱秸秆

- 稻草

- 玉米秸秆

作物加工副产品

- 玉米芯

- 稻壳

坚果和棕榈废料

- 花生壳

- 棕榈壳

- 其他农业加工残渣

木屑压块生产工艺

该生物质压块生产线主要包括木材碎片机、木材破碎机、木屑干燥机和生物质压块机。通过破碎、干燥、炭化和成型等工艺,将原料加工成高密度生物质燃料——生物质木屑压块。

- 功能高效将大木料或树枝转化为均匀的木屑或碎木。

- 核心组件带切割刀的旋转鼓,用于精确木材切割。

- 容量每小时10–15吨,适合大规模生产。

- 应用领域林业、木工和生物质加工。

- 优点高效率、稳定输出、适用范围广。

- 与盘式碎木机的区别鼓式更适合大批量连续生产。

- 功能粉碎原料——原木、硬木、树枝和农作物稻草——成更小的颗粒,便于处理和加工。

- 用途为高品质压块的平稳高效生产准备木屑。

- 可调细度配备不同孔径的可更换筛网,以生产不同粒径的木屑。

- 典型用途松木锯末用于松木块的尺寸通常在5毫米左右。

木屑干燥机

- 功能将木屑的含水率降低到最佳水平,以实现平稳高效的压块生产。

- 类型鼓式干燥机,常用于粉末和颗粒材料。

- 含水率控制调节木屑含水率至12%以下,以确保高品质压块。

- 功能将木屑、木屑和稻草转化为高密度燃料压块。

- 容量160–320公斤/小时,适合小到大型生产。

- 技术双螺杆挤出,配备智能温控,压缩比超过8:1。

- 热值热值:4000–4500千卡/公斤,最大化生物质能利用。

- 多功能模块化模具系统支持6–80毫米的方形和圆形压块。

- 应用: 用于锅炉、发电和家庭燃料,推动绿色循环经济。

木屑压球生产线的优点

- 支持多种原料处理木屑、木屑、树枝、稻草及其他农业或林业残余物,实现废料的高效利用。

- 高容量与稳定性生产取决于压块机的数量,每台机器大约生产 250 kg/h。 最常见的生产线输出为1吨/小时。Shuliy可以根据任何规模配置生产线,确保连续高效运行。

- 高品质燃料压块密实,含水率低,具有高燃烧效率和热值, 每千克热值:4000–4500 千卡适用于锅炉、发电和家庭取暖。

- 多样尺寸支持模块化模具系统 6–80毫米 满足不同客户需求的方形和圆形压块。

- 环保且经济实惠减少生物质废料,促进绿色生产和循环经济,成本低,投资回报快。

- 灵活支持无论是新建工厂还是扩建现有生产线,Shuliy都提供完整解决方案和促销优惠。

成品展示

我们的木屑/生物质压块均匀、高密度、含水率低,热值为4000–4500 kcal/kg。支持6–80 mm的方形或圆形,适用于锅炉、发电和家庭取暖,提供环保高效的能源解决方案。

1000公斤/小时木屑压块机线——主要设备清单

| 设备名称 | 主要规格(毫米) | 力量 |

|---|---|---|

| 木屑机 | 容量:1000公斤/小时; 除尘器 直径:1000毫米; 6个除尘袋 | 45千瓦(主电机) 7.5千瓦(风扇) |

| 螺旋输送机 | 直径:219毫米; U型; 长度:6米 | 4千瓦 |

| 旋转干燥机 | 容量:1000公斤/小时; 鼓直径:1000毫米; 厚度:10毫米; 重量:2800 kg | 3千瓦(主电机) 15千瓦(风扇) |

| 螺旋输送机 | 直径:273毫米; U型;长度:4米 | 4千瓦 |

| 螺旋喂料机 | 均匀分布物料 至4台压块机, 带保护罩 | 5.5千瓦 |

| 木屑压块机 | 容量:每套200–250公斤/小时; 尺寸:1770 × 700 × 1450毫米; 重量:每套550公斤 | 每套18.5千瓦 |

| 烟尘收集器 | 包括风扇和净化系统 | 4千瓦 |

| 皮带输送机 | 用于收集和 输送成品压块; 带控制柜 | 1.5千瓦 |

整体技术参数

| 物品 | 规格 |

|---|---|

| 设计容量 | 每小时1吨 |

| 总压块产量 | 800–1000公斤/小时 |

| 总装机功率 | 163.5千瓦 |

| 所需工作面积 | 200–300平方米 |

| 所需劳动力 | 3–4名工人 |

关键配置细节

| 设备 | 关键配置 |

|---|---|

| 木屑机 | 筛孔尺寸可选:0.6–12毫米; 配备气锁和控制柜;易损件:锤子和筛网 |

| 旋转干燥机 | 配备1米旋风分离器; 标准磁线圈;可调速电机;独立控制柜 |

| 压块机 | 模具材料:铬锰合金; C型皮带;国家标准铜电机;加强型轴承;U型钢框架结构 |

相关产品——炭机生产线

炭化机生产线旨在将木材、竹子和稻草等生物质材料转化为高品质炭。该生产线集破碎、干燥、炭化和成型于一体,自动化高效。成品炭密实、燃烧时间长、热值稳定,非常适合工业燃料、家庭取暖和烧烤使用。

该生产线可视为木屑压块生产线的扩展:通过在压块线上添加炭化炉,木屑和其他生物质颗粒可以直接转化为高品质炭,最大化生物质利用率,提供完整的绿色能源解决方案。

热门产品

竖式碳化炉用于硬木炭制作

该立式炭化炉可用于…

连续炭化炉 | 锯末炭黑制造机

连续式碳化炉用于大规模的…

水烟炭包装机

我们的水烟木炭包装机是一个重要的…

动物饲料颗粒机 | 颗粒饲料厂机器

Shuliy提供动物饲料颗粒机,…

烧烤炭用木炭压块机

我们的炭球包装机,即烧烤炭…

木材锤磨机 | 锤式破碎机

木质锤式磨粉机高效粉碎木屑,…

炭块机 | 炭挤出机

炭球机,也称为…

便携式木工锯机 | 木材锯割机

便携式木材锯床具有出色的…

圆盘式木材碎片机 | 木屑制造机

圆盘木材粉碎机是一种多功能解决方案…