特点一览

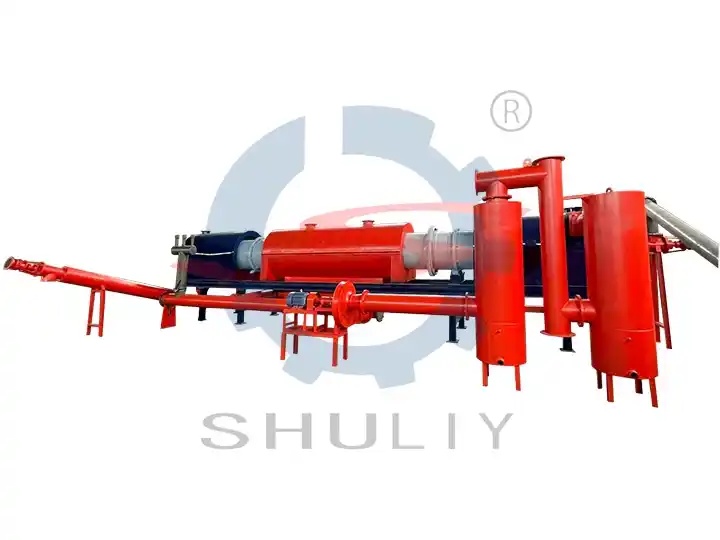

连续碳化炉旨在大规模生产高质量的木炭,原料包括各种 生物质材料,如稻壳、椰子壳、木屑、锯末, 和其他类似材料。

具有 400-2000千克/小时的能力, 它在高温条件下运行,以实现无氧、干燥的干馏,从而使稻草、棕榈仁壳和竹屑等材料的碳化率达到较高水平。

这使得连续的碳化炉成为希望有效生产可持续木炭的企业的理想解决方案。

连续碳化炉出售

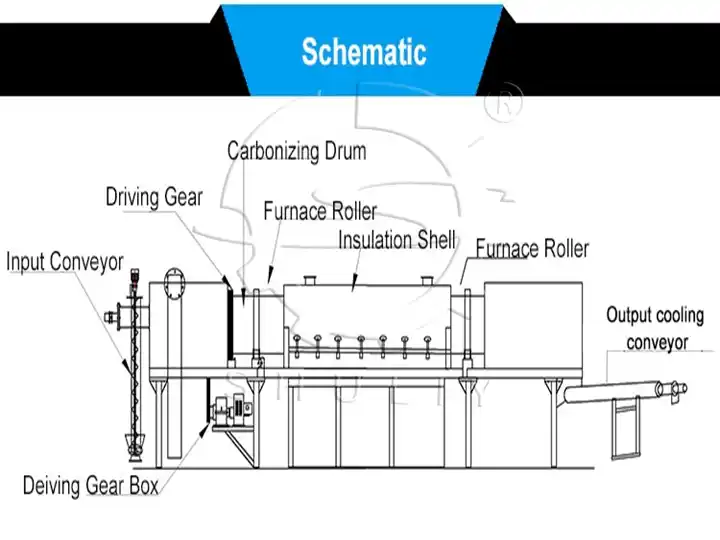

连续碳化炉由一个 螺旋进料系统、水平进料、旋转鼓、冷凝排放、燃烧器、燃烧室、净化单元和控制柜组成。

连续碳化炉的示意图

核心组件展示

- 碳化剂。 将生物量转化为木炭的核心单元。

- 加油站。 在碳化过程中促进可燃气体的产生。

- 烟灰处理器。 过滤杂质并防止有害颗粒的排放。

- 可燃气体净化器。 清除气体中的污染物,以确保清洁排放。

- 可燃气管冷凝器。 收集并凝结气体以供进一步使用。

- 诱发的选秀迷。 在整个系统中促进气体循环以保持有效的运行。

连续碳化炉由几个关键组件组成,这些组件协同工作,以生产高质量的木炭,同时最小化对环境的影响。

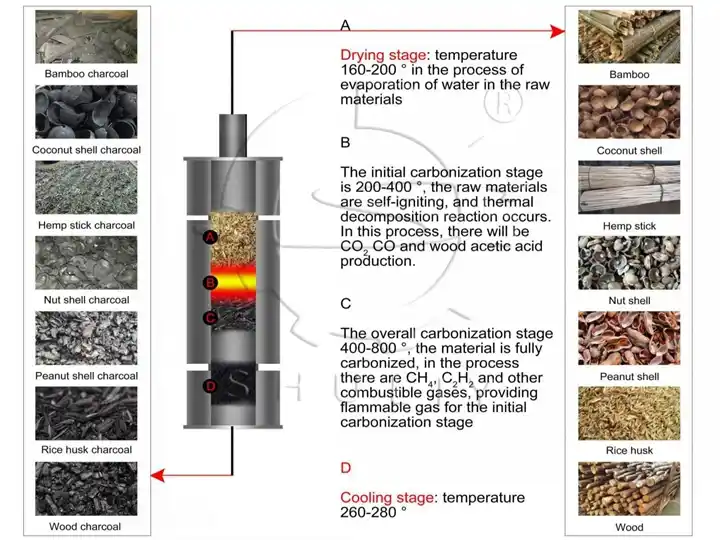

连续碳化炉的生产过程

连续的碳化炉是通过利用从燃烧过程产生的热量来启动生物质原料的热解的作用。

随着材料通过旋转鼓的移动,它会受到仔细控制的高温,从而破坏复杂的有机化合物并释放挥发性气体。

然后在燃烧室中燃烧这些气体,从而显着提高炉的能效,同时最大程度地减少有害排放。

- 热能利用利用燃烧热量启动生物质原料的热解。

- 旋转鼓。 生物质在鼓内移动,确保均匀暴露于高温下。

- 高效分解。 高温分解有机化合物并释放挥发性气体。

- 能量最大化挥发性气体在燃烧室中燃烧,以实现最佳能量利用。

- 减少排放在生产过程中产生的木焦油和木醋被燃烧,确保没有环境污染。水是可回收的,有助于节约和保护水资源。

连续式炭化炉规格

热销连续碳化炉:

| 模型 | SL-CF800 | SL-CF1000 | SL-CF1200 |

| 直径(毫米) | 800 | 1000 | 1200 |

| 产能(公斤/小时) | 400-600 | 800-1000 | 1200-2000 |

| 主功率(kw) | 18.5 | 18.5 | 20 |

| 炭化温度(℃) | 500-800 | 500-800 | 500-800 |

| 风机功率(kw) | 5.5 | 5.5 | 5.5 |

我们支持定制服务。如果您想了解更多关于我们的型号和产品详情,请随时与我们联系!

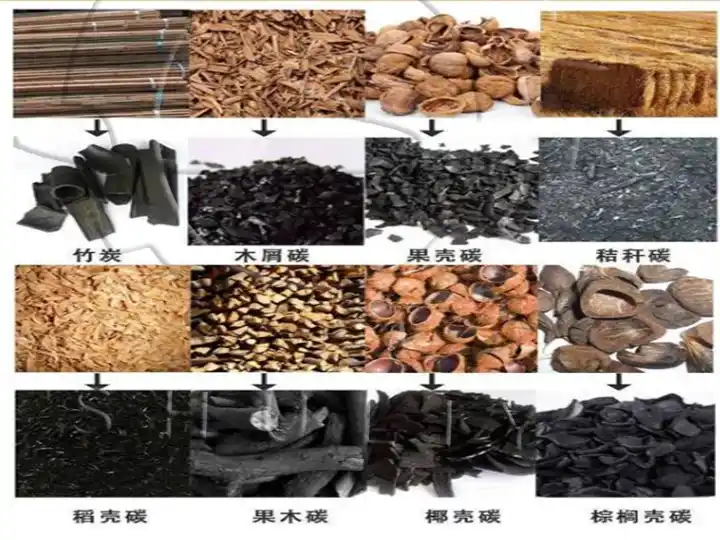

哪些材料适合木屑制造机器?

锯末木炭制造机能够处理多种原材料,使其具有高度的用途。

它可以处理生物质、污泥、垃圾和其他材料,只要它们的尺寸低于 15厘米 水分含量低于 15%.

这些材料可以直接碳化,从而使木炭的有效生产有效。

- 生物质材料(例如木屑,花生贝壳,玉米茎和稻壳)

- 农业残留物(例如,腌渣,高粱茎和棉茎)

- 林业垃圾(例如竹片,树枝和棕榈贝壳)

- 其他有机废物(例如,蒸馏器的谷物,玉米面和死叶)

- 来自各个行业的副产品(例如,咖啡渣,杏和中医残留物)

- 各种植物茎(例如,向日葵种子壳,山药草和大麻茎)

这些材料都可以在连续的碳化炉中有效加工,以生产高质量的木炭。

连续碳化炉的优势

- 高效率。 通过消除频繁的加载和卸载来实现连续操作,提高生产率。

- 一致的输出。 确保碳化均匀,从而导致最终木炭的质量一致。

- 能源效率。 利用热回收系统回收烟道气和废热,以减少能耗。

- 灵活性。 适应各种原材料和碳化设置,例如温度,停留时间和气流。

- 自动控制。 具有高级自动化,以进行精确监控,增强安全性并最大程度地减少人类干预。

- 环境友善。 将粉尘清除和排放控制系统结合在一起,以满足环境标准并减少污染。

- 节省成本。 降低劳动力和能源成本,而其高质量产出提高了市场的竞争力和盈利能力。

连续碳化炉的技术功能

- 高自动化。 具有高温密封的先进技术的组装线生产,可在各种环境(真空,正压,大气保护,无氧)中碳化。

- 可调温度范围。 温度可以从50-1000°C精确控制以满足特定的产品要求。

- 正常压力操作。 确保车间中的最小灰尘确保卓越的操作条件。

- 低空气体积。 通过需要最小的空气体积来降低灰尘收集系统的压力。

- 受控的发射时间。 可以调整发射时间以确保均匀碳化。

- 能源回收。 全面的热能回收提高了热能利用效率。

- 多个温度区。 内缸可以根据产品特性具有多个用于温度控制的区域。

- 溶剂恢复。 方便从材料中回收溶剂。

- 高填充材料速率。 通过热烟气气体达到最佳热量交换的15%填充材料速率,最大速率为25%。

木屑木炭制造机器如何工作?

- 偏转器机制。 原材料进入碳化主炉,并在熔炉的旋转下水平移动。

- 连续碳化。 该材料在运动过程中经过碳化时逐渐从进料入口移动到碳插座。

- 气锁。 饲料和碳插座都配备了空气锁,以防止空气进入,并保持贫困的环境。

- 诱导的风扇。 主炉配备了诱导的风扇,以在连续喂养和碳化过程中保持贫气的气氛。

- 连续操作。 该设计允许连续进食和碳化,增强效率和生产能力。

- 改善的碳化结果。 耗氧环境可确保更好的碳化质量,是生产木炭和竹木炭的理想选择。

连续碳化炉中的客户案例

在一个非凡的成功故事中,来自刚果的客户向 Shuliy 工厂订购了连续式碳化炉和木炭研磨机。

这些机器的产量高达 800-1000 公斤/小时,是专门为促进高品质烧烤木炭的生产和销售而选择的。

联系我们

总之,连续 碳化 Furnace 是可持续木炭生产领域的创新灯塔。其连续工艺、高效生物质转化和环保操作使其成为寻求绿色实践的行业不可或缺的资产。

此外,我们很自豪能够提供另外两种型号的碳化炉: 提升式炭化炉 和 卧式碳化炉.

每种型号都具有独特的功能,可以满足木炭生产和可持续能源解决方案的不同需求。探索我们的碳化炉系列,彻底改变您当今的木炭生产方法。

热门产品

便携式木材锯木机|木材锯床

便携式木材锯木机具有...

鼓式木材削片机

鼓式木材削片机用于......

水烟木炭包装机

我们的水烟木炭包装机是一个重要的……

木炭粉碎机| 木炭粉碎机|木炭研磨机

该木炭粉碎机可以粉碎木质原料……

综合破碎机|木托盘撕碎机

综合破碎机,俗称……

箱式木炭烘干机

该箱式木炭烘干机是......

用于生产生物炭的卧式木炭炉

水平木炭炉是一种高性能的设备……

木炭搅拌机|木炭粉搅拌机

该木炭搅拌机也可命名为……

型煤机|蜂窝压煤机

型煤机可生产不同形状和......