Línea de producción de briquetas de aserrín de madera para Pini Kay

Planta de troncos de calor de Pini Kay | Línea de procesamiento de briquetas de aserrín.

Línea de producción de briquetas de aserrín de madera para Pini Kay

Planta de troncos de calor de Pini Kay | Línea de procesamiento de briquetas de aserrín.

Funciones de un vistazo

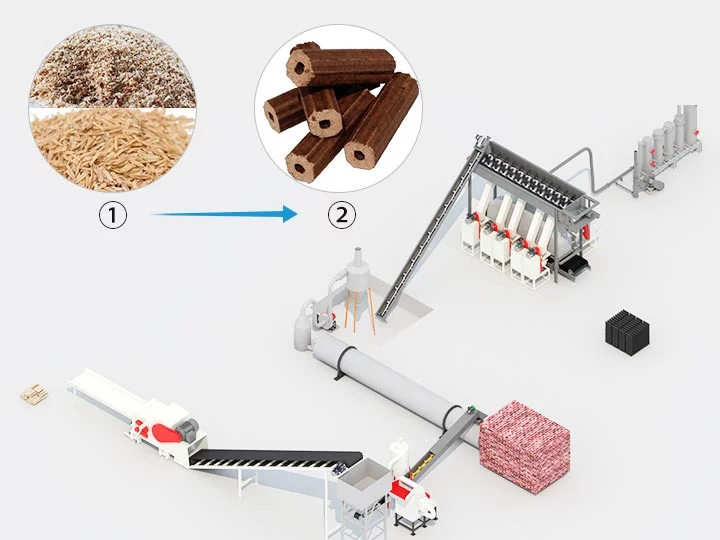

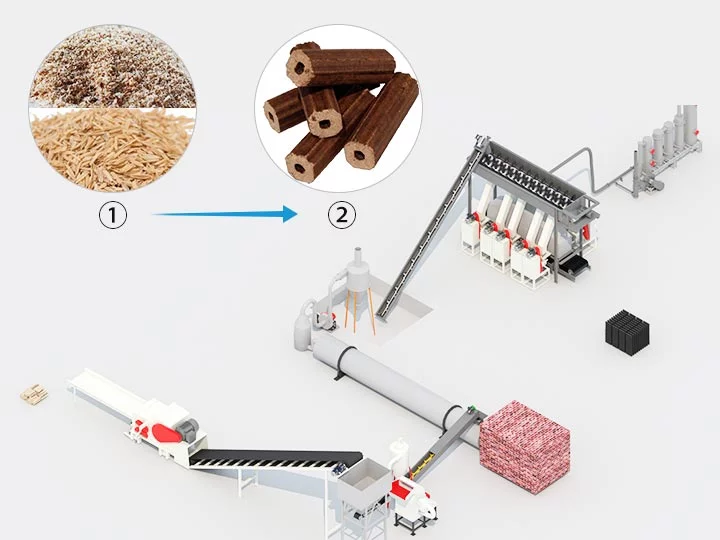

Esta línea de producción de briquetas de aserrín de madera, también conocida como planta de procesamiento de pini kay, se utiliza para convertir aserrín y otras materias primas en combustible de biomasa conocido como troncos de calor de pini kay. El equipo principal de esta línea incluye un astillador de madera, trituradora de madera, secador rotatorio de aserrín, máquina de briquetas de aserrín y transportadores de tornillo. Puede producir de manera eficiente briquetas de pini kay de alta calidad, ecológicas y ampliamente utilizadas para calefacción y cocina. Contáctenos para precios promocionales.

La capacidad de esta línea de producción de briquetas de aserrín de madera se determina principalmente por el número de máquinas de briquetas. Cada máquina tiene una capacidad de 250 kg/h. La configuración más común de esta línea es 1 tonelada por hora.

Independientemente de la producción requerida, Shuliy puede personalizar y configurar la línea de producción según sus necesidades. Contáctenos a través del chat en línea en la derecha para más detalles.

Aplicación de la línea de producción de briquetas de aserrín de madera

La aplicación de la línea de producción de briquetas de aserrín de madera es vital en la producción de combustible de biomasa de alta calidad conocido como leños térmicos pini kay. Esta línea de producción industrial procesa eficientemente aserrín o cáscaras de arroz extruyéndolos a altas temperaturas y presiones.

Los troncos de calor Pini Kay producidos mediante este proceso tienen numerosas aplicaciones en diversas industrias y sectores. Sirven como una alternativa ecológica y sostenible a los combustibles convencionales como el carbón y el carbón vegetal. Estas briquetas se utilizan ampliamente para calentar, cocinar y generar energía. Los hogares residenciales, los establecimientos comerciales y las instalaciones industriales pueden beneficiarse de la fuente de energía limpia y eficiente que proporciona la planta de procesamiento de pini kay.

Materia prima para la producción de briquetas de aserrín de madera.

Además de materias primas comunes como troncos, maderas duras y ramas de árboles (por ejemplo, pino y roble), la línea de producción puede procesar una amplia gama de materiales de biomasa.

Materiales a base de madera

- Troncos y maderas duras

- Ramas de árboles y recortes de madera

- Aserrín y virutas de madera

Residuos agrícolas

- Tallossas de algodón

- Tallossas de sorgo

- Paja de arroz

- Tallossas de maíz

Subproductos del procesamiento de cultivos

- Mazorcas de maíz

- Cáscaras de arroz

Residuos de nueces y palmas

- Cáscaras de cacahuete

- Cáscaras de palma

- Otros residuos de procesamiento agrícola

Proceso de producción de briquetas de aserrín de madera

Esta línea de producción de briquetas de biomasa principalmente incluye un astillador de madera, trituradora de madera, secador de aserrín y máquina de briquetas de biomasa. A través de procesos como astillado, trituración, secado y briquetado, las materias primas se procesan en combustible de biomasa de alta densidad— briquetas de aserrín de biomasa.

Astilladora de madera estilo tambor

- Función: Convierte eficientemente grandes troncos o ramas en astillas de madera o aserrín uniformes.

- Componente principal: Tambor giratorio con cuchillas para corte preciso de madera.

- Capacidad: 10–15 toneladas por hora, ideal para producción a gran escala.

- Aplicaciones: Silvicultura, carpintería y procesamiento de biomasa.

- Ventajas: Alta eficiencia, producción consistente y amplia aplicabilidad.

- Diferencias con astilladoras de disco: El estilo de tambor es más adecuado para producción en volumen alto y continua.

Trituradora de madera / Trituradora

- Función: Tritura materias primas—troncos, maderas duras, ramas y pajas agrícolas—en partículas más pequeñas para facilitar su manejo y procesamiento.

- Propósito: Prepara el aserrín para una producción suave y eficiente de briquetas de alta calidad.

- Fineness ajustable: Equipado con pantallas intercambiables de diferentes tamaños de orificio para producir aserrín con diferentes tamaños de partículas.

- Uso típico: El aserrín para briquetas de pini kay suele tener alrededor de 5 mm de tamaño.

Secador de aserrín

- Función: Reduce el contenido de humedad del aserrín a un nivel óptimo para una producción de briquetas suave y eficiente.

- Tipo: Secador de tambor, comúnmente usado para polvos y materiales granulados.

- Control de humedad: Ajusta la humedad del aserrín por debajo del 12% para garantizar briquetas de alta calidad.

Máquina para fabricar briquetas de aserrín

- Función: Convierte aserrín, virutas de madera y paja en briquetas de combustible de alta densidad.

- Capacidad: 160–320 kg/h, adecuado para producción pequeña a grande.

- Tecnología: Extrusión de doble tornillo con control inteligente de temperatura, logrando una relación de compresión superior a 8:1.

- Valor calorífico: 4000–4500 kcal/kg, maximizando la utilización de energía de biomasa.

- Versatilidad: Sistema de moldes modulares que soporta briquetas cuadradas y redondas de 6–80 mm.

- Aplicaciones: : Caldera, generación de energía y combustible doméstico, promoviendo una economía circular ecológica.

Ventajas de la línea de producción de briquetas de aserrín

- Admite múltiples materias primas: Procesa aserrín, virutas de madera, ramas, paja y otros residuos agrícolas o forestales para un uso eficiente de los desechos.

- Alta capacidad y estabilidad: La producción depende del número de máquinas de briquetas, con cada máquina produciendo alrededor de 250 kg/h. La producción más común de línea es de 1 t/h. Shuliy puede configurar la línea para cualquier escala, asegurando operación continua y eficiente.

- Combustible de alta calidad: Las briquetas son densas con bajo contenido de humedad, ofreciendo alta eficiencia de combustión y un valor calorífico de 4000–4500 kcal/kg, apto para calderas, generación de energía y calefacción doméstica.

- Tamaños versátiles: Sistema de moldes modulares que soporta 6–80 mm briquetas cuadradas y redondas para satisfacer diferentes requisitos del cliente.

- Ecológico y rentable: Reduce residuos de biomasa, promueve la producción ecológica y la economía circular, con bajo costo y rápida recuperación de inversión.

- Soporte flexible: Ya sea para comenzar una nueva planta o ampliar una línea existente, Shuliy ofrece soluciones completas y ofertas promocionales.

Muestra del Producto Terminado

Nuestras briquetas de aserrín de madera/biomasa son uniformes, de alta densidad y con bajo contenido de humedad, con un valor calorífico de 4000–4500 kcal/kg. Disponibles en formas cuadradas o redondas de 6–80 mm, son ideales para calderas, generación de energía y calefacción doméstica, ofreciendo una solución energética ecológica y eficiente.

Línea de máquina de briquetas de aserrín de 1000 kg/h – Lista de equipos principales

| Nombre del equipo | Especificaciones principales (mm) | Fuerza |

|---|---|---|

| Máquina de aserrín de madera | Capacidad: 1000 kg/h; Extractor de polvo diámetro: 1000 mm; 6 bolsas de polvo | 45 kW (motor principal) 7.5 kW (ventilador) |

| Transportador de tornillo | Diámetro: 219 mm; Tipo U; Longitud: 6 m | 4 kW |

| Máquina de secado rotatorio | Capacidad: 1000 kg/h; Diámetro del tambor: 1000 mm; Grosor: 10 mm; Peso: 2800 kg | 3 kW (motor principal) 15 kW (ventilador) |

| Transportador de tornillo | Diámetro: 273 mm; Tipo U; Longitud: 4 m | 4 kW |

| Alimentador de tornillo | Distribuye el material de manera uniforme hasta 4 máquinas de briquetas, con cubierta protectora | 5.5 kW |

| Máquina de briquetas de aserrín | Capacidad: 200–250 kg/h por conjunto; Dimensión: 1770 × 700 × 1450 mm; Peso: 550 kg por conjunto | 18.5 kW por conjunto |

| Recolector de humo | Incluye ventilador y sistema de purificación | 4 kW |

| Cinta transportadora | Para recolectar y transportando briquetas terminadas; Con armario de control | 1.5 kW |

Parámetros técnicos generales

| Artículo | Especificación |

|---|---|

| Capacidad diseñada | 1 tonelada/hora |

| Producción total de briquetas | 800–1000 kg/h |

| Potencia total instalada | 163.5 kW |

| Área de trabajo requerida | 200–300 m² |

| Mano de obra requerida | 3–4 trabajadores |

Detalles clave de configuración

| Equipo | Configuración clave |

|---|---|

| Máquina de aserrín de madera | Tamaño de pantalla opcional: 0.6–12 mm; Equipado con separador ciclónico de 1 m y armario de control; |

| Secador rotatorio | Equipado con separador ciclónico de 1 m; Bobina magnética estándar; motor de velocidad ajustable; armario de control independiente |

| Máquina de briquetas | Material del molde: aleación de cromo-manganeso; Correa en C; motor de cobre de estándar nacional; rodamiento reforzado; estructura de marco de acero U; |

Producto relacionado – Línea de producción de máquinas de carbón vegetal

La línea de producción de máquinas de carbón vegetal está diseñada para convertir materiales de biomasa como madera, bambú y paja en carbón de alta calidad. La línea integra trituración, secado, carbonización y conformado en un proceso totalmente automatizado y eficiente. El carbón terminado es denso, de larga duración y tiene un valor calorífico estable, lo que lo hace ideal para combustible industrial, calefacción doméstica y uso en barbacoas.

Esta línea de producción puede considerarse una extensión de la línea de briquetas de aserrín de madera: añadiendo un horno de carbonización a la línea de briquetas, se pueden transformar directamente aserrín y otras pellets de biomasa en carbón vegetal de alta calidad, maximizando la utilización de biomasa y proporcionando una solución energética verde completa.

Producto caliente

Horno de carbonización continua | Máquina de hacer carbón de aserrín

El Horno de Carbonización Continua es para la gran escala…

Máquina portátil de aserradero de madera | Máquina de aserrado de madera

La máquina aserradora portátil de madera tiene un gran…

Mezclador de carbón | Mezclador de polvo de carbón

Esta mezcladora de carbón también puede denominarse…

Secador de banda de malla para briquetas de carbón

El secador de cinta de malla, también conocido como el…

Máquina de carbón para shisha para carbón de hookah redondo y en cubo

Nuestra popular máquina de carbón para shisha puede producir carbón de alta calidad…

Máquina de embalaje con película retráctil | Máquina de embalaje de briquetas de carbón

Nuestra máquina de embalaje con película retráctil por calor, también conocida…

Trituradora de madera integral | Trituradora de palets de madera

La trituradora integral, comúnmente denominada…

Trituradora de madera de estilo tambor

Una astilladora de madera de tambor se utiliza en…

Máquina de descortezado de madera | Máquina de pelado de troncos

Máquina descortezadora de madera, también conocida como peladora de troncos…