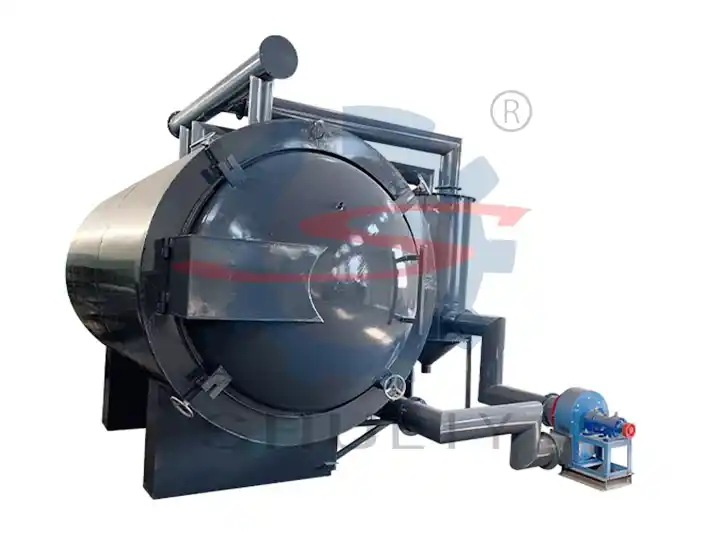

Horno de carbón horizontal para producir biocarbón

Máquina para fabricar carbón vegetal | Horno de carbón de leña

Horno de carbón horizontal para producir biocarbón

Máquina para fabricar carbón vegetal | Horno de carbón de leña

Funciones de un vistazo

El horno de carbón horizontal es un equipo de alto rendimiento diseñado para una carbonización industrial eficiente y ecológica. Con una estructura horizontal innovadora, integra una tecnología de control de temperatura precisa y un sistema de combustión que ahorra energía.

Con una capacidad de procesamiento diario de 900-3000 kg (12-14 horas por lote), satisface las necesidades de producción de pequeña a gran escala. Este horno se usa ampliamente en la producción de carbón de biomasa, fabricación de carbono activado, tratamiento térmico de metal y procesamiento de materias primas químicas.

Aplicación del horno de carbón horizontal

El horno de carbón horizontal, también conocido como el horno de carbón de registro o máquina para fabricar carbón horizontal, es una solución de carbonización altamente versátil y eficiente.

Diseñado para la producción a escala industrial, convierte varios materiales de biomasa, como chips de madera, aserrín y desechos agrícolas, en carbón o biochar de alta calidad a través de un proceso de carbonización controlado.

- Agricultura y silvicultura - Utilizado para procesar los residuos agrícolas y forestales en biochar para la mejora del suelo y el secuestro de carbono.

- Protección ambiental -Ayuda a reducir los desechos al convertir la biomasa en carbón ecológico, apoyando soluciones de energía sostenible.

- Producción de carbón comercial -Ideal para empresas que requieren carbonización a gran escala y alta eficiencia para producir carbón de carbón para combustible, carbono activado o aplicaciones industriales.

Para satisfacer diversas necesidades de carbonización, también ofrecemos hornos de carbonización continua, hornos de carbonización de flujo de aire verticaly otros modelos especializados.

¿Cómo funciona la máquina de fabricación de carbón horizontal?

- Carga de biomasa. Los materiales de biomasa se cargan en el horno de carbón horizontal.

- Generación de encendido y calor. El horno se enciende, generando calor dentro de la cámara e iniciando el proceso de carbonización.

- Control de temperatura. La temperatura generalmente se controla a aproximadamente 600 ℃.

- Incluso calefacción. El diseño horizontal garantiza un calentamiento incluso de los materiales de biomasa.

- Liberación de gases y volátiles. Los gases evolucionados y los componentes volátiles se liberan durante esta fase.

- Flujo de aire controlado. El flujo de aire controlado se mantiene dentro del horno horizontal.

- Eliminación eficiente. Esto garantiza la eliminación eficiente de la humedad, las sustancias volátiles y otras impurezas de los materiales de biomasa.

- Transformación gradual. Los materiales sufren una transformación gradual, convirtiéndose en carbón de alta calidad.

Ventajas del diseño horizontal

- Flujo de aire óptimo. También proporciona un flujo de aire óptimo, que es crucial para la eliminación eficiente de las impurezas y la producción de carbón de alta calidad.

- Distribución de calor uniforme. El diseño horizontal garantiza una distribución de calor uniforme durante todo el proceso de carbonización.

La máquina de carbón horizontal aprovecha su diseño único para garantizar una carbonización eficiente y la producción de productos de carbón superiores.

Al mantener el flujo de aire controlado y la distribución de calor uniforme, facilita la transformación gradual de los materiales de biomasa en carbón de alta calidad.

Proceso de carbonización en el horno de carbón de registro

El proceso de carbonización En un horno de carbón de registro sigue una secuencia estructurada para garantizar Producción de carbón eficiente y controlada. Al utilizar un sistema bien diseñado, el horno convierte efectivamente las materias primas en carbón de alta calidad a través de un proceso de combustión cíclica.

- Cargando las materias primas

- Secciones de registro y ramas están cuidadosamente organizados dentro de un marco de hierro, que luego se empuja suavemente hacia la cavidad del horno usando una pista transportadora.

- Alternativamente, Cadrones de coco, ramas rotas y otros materiales de biomasa se puede cargar directamente en el barril de horno del horno de carbón horizontal.

- Sellando el horno

- El cubierta del horno de carbón horizontal de flujo de aire está cerrado de forma segura.

- Cualquier hueco cerca de la cubierta son sellado con barro o aislamiento algodón Para evitar la fuga de aire y garantizar un ambiente hermético.

- Encendido y calefacción inicial

- A horno de gasificación se usa para encender el combustible en el puerto de encendido en la parte inferior del horno.

- A medida que el combustible arde, la temperatura dentro del horno aumenta gradualmente.

- Monitoreo de temperatura y circulación de gas

- El termómetro de horno se monitorea de cerca. Cuando la temperatura alcanza 400 ° C, el horno de gasificación está apagado.

- En esta etapa, el Gas combustible producido dentro del horno de carbonización sufre combustión cíclica, reduciendo la necesidad de combustible externo.

- Carbonización final y formación de carbón

- El proceso de calentamiento cuidadosamente regulado asegura transformación efectiva de materias primas en carbón de alta calidad.

- El controlado Distribución de flujo de aire y calor contribuir a un proceso de carbonización consistente y eficiente.

Siguiendo estos pasos sistemáticos, el horno de carbón de registro maximiza eficiencia de combustible, minimiza desperdiciar, y asegura Producción de carbón de alta salida, lo que lo convierte en una solución ideal para las necesidades de carbonización comercial.

Parámetro del horno de carbón horizontal

| Modelo | Capacidad | Peso de la máquina | Dimensiones (L × W × H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg/12–14 horas | 2500 kg | 3 × 1.7 × 2.2 metros |

| SL-1500 | 1500–2000 kg/12–14 horas | 4000 kg | 4.5 × 1.9 × 2.3 metros |

| SL-1900 | 2500–3000 kg/12–14 horas | 5500 kg | 5 × 2.3 × 2.5 metros |

Estructura del horno de carbón horizontal

Aislamiento térmico mejorado

- Las superficies de roca de aislamiento térmico altamente eficientes se integran en la tapa y el cuerpo del horno, lo que garantiza una retención de calor superior.

- El diseño avanzado de sellado mejora el aislamiento térmico, evitando la pérdida de calor durante el proceso de carbonización.

- La construcción optimizada del horno mantiene temperaturas internas estables, mejorando la eficiencia energética general.

Circulación de gases de combustión eficiente

- Una red de tuberías está integrada en el horno, conectando las secciones superior e inferior para optimizar el flujo de gas.

- Las tuberías circulantes facilitan el movimiento de gas combustible dentro del cilindro, mejorando la eficiencia energética.

- Las tuberías adicionales están diseñadas para filtrar gas de combustión, mejorando el rendimiento ambiental del horno.

Sistema de tranvía conveniente

- Se incluyen sistemas de tranvía para facilitar el transporte de materias primas y carbón terminado.

- Diseñado para manejar la capacidad sustancial del horno y la alta salida, asegurando un funcionamiento suave.

- Mejora la eficiencia y la conveniencia general, reduciendo la intensidad laboral para los operadores.

Características de la máquina de fabricación de carbón horizontal

- Cuerpo de horno de tres capas. El cuerpo del horno está construido con tres capas, y la puerta está bordeada de algodón de algodón con retardantes de llama y a insulento con calor, asegurando una excelente opresión del aire, retención de calor y eficiencia energética al tiempo que reduce el consumo de combustible.

- Sistema de recuperación de gases de combustión. La tecnología integrada de recuperación de gases de combustión mejora la eficiencia del combustible, minimizando los desechos de recursos.

- Diseño de coches de horno. El automóvil de horno móvil simplifica la operación, reduciendo la intensidad del parto y haciendo que la carga y la descarga sean más convenientes.

- Alta capacidad y carbonización única. La máquina acomoda grandes cargas de material, lo que permite una carbonización de lotes eficiente.

- Opciones de calefacción múltiples. Compatible con varias fuentes de combustible, incluidas la madera, el carbón y el gas natural, proporcionando flexibilidad basada en la disponibilidad y el costo.

- Emisiones libres de humo. Un sistema de purificación de gas de combustible de alto rendimiento garantiza una operación ecológica con emisiones de humo mínimas.

- Sistema de enfriamiento de agua. Un sistema de enfriamiento rápido acelera el proceso, mejorando la eficiencia general y la productividad.

Contáctenos

Si está interesado en nuestro producto y desea conocer más detalles o solicitar un presupuesto, no dude en contactarnos.

Nuestro equipo profesional se dedica a brindarle apoyo y asistencia para ayudarlo a alcanzar sus objetivos de producción de carbón. Toma medidas ahora y únete a nosotros para dar forma al futuro de Sostenible carbón ¡producción!

Producto caliente

Secador de cinta de malla para briquetas de carbón

El secador de cinta de malla, también conocido como…

Molino de martillos para madera | Trituradora de molino de martillos

El molino de martillos para madera tritura eficientemente astillas de madera,...

Máquina empacadora de briquetas de carbón para carbón de barbacoa

Nuestra máquina envasadora de briquetas de carbón, concretamente carbón para barbacoa...

Máquina trituradora de carbón | Máquina trituradora de carbón

Esta máquina trituradora de carbón puede triturar materias leñosas ...

Máquina de aserradero de madera portátil | Sierra de madera

El aserradero de madera portátil tiene excelentes...

Horno de carbonización continua | Máquina para fabricar carbón de aserrín

El horno de carbonización continua es para la producción a gran escala…

Máquina trituradora de madera | Máquina trituradora de madera industrial

Las máquinas trituradoras de madera están diseñadas para procesar eficientemente...

Máquina para fabricar briquetas de aserrín | Máquina de briquetas de biomasa

La máquina para fabricar briquetas de aserrín es una solución ecológica...

Máquina descortezadora de madera | Peladora de troncos

Máquina descortezada de madera, también conocida como Tro…