Mesin pembuat palet kayu ke Senegal

Sebagai pemasok dari Mesin Pembuat Palet Kayu, kami baru-baru ini mengirimkan salah satu mesin kami ke perusahaan manufaktur yang berkembang pesat di Senegal.

Latar belakang pelanggan

Pelanggan kami, yang berbasis di Dakar, Senegal, adalah produsen solusi pengemasan terkemuka, yang memasok palet untuk industri lokal seperti pertanian, logistik, dan ekspor.

Mereka mencari solusi yang lebih efisien dan otomatis untuk memenuhi kebutuhan produksi mereka yang terus meningkat sekaligus memastikan kualitas dan keberlanjutan.

Persyaratan utama mesin pembuat palet kayu

Klien memiliki kebutuhan spesifik untuk Mesin Pembuat Palet Kayu untuk memenuhi permintaan produksi mereka yang terus berkembang:

- Meningkatkan kapasitas produksi. Mereka membutuhkan mesin yang mampu meningkatkan produksi harian mereka secara signifikan untuk memenuhi permintaan yang meningkat.

- Pertahankan kualitas yang konsisten. Palet yang diproduksi harus mematuhi standar industri, memastikan kekuatan dan daya tahan untuk berbagai aplikasi.

- Mengurangi biaya tenaga kerja. Otomatisasi sangat penting untuk menyederhanakan operasi, meminimalkan tenaga kerja manual, dan meningkatkan efisiensi secara keseluruhan.

- Mendukung keberlanjutan. Klien mencari mesin yang dapat memproses kayu daur ulang, sejalan dengan komitmen mereka terhadap praktik ramah lingkungan sekaligus mengurangi biaya material.

Solusi yang disesuaikan

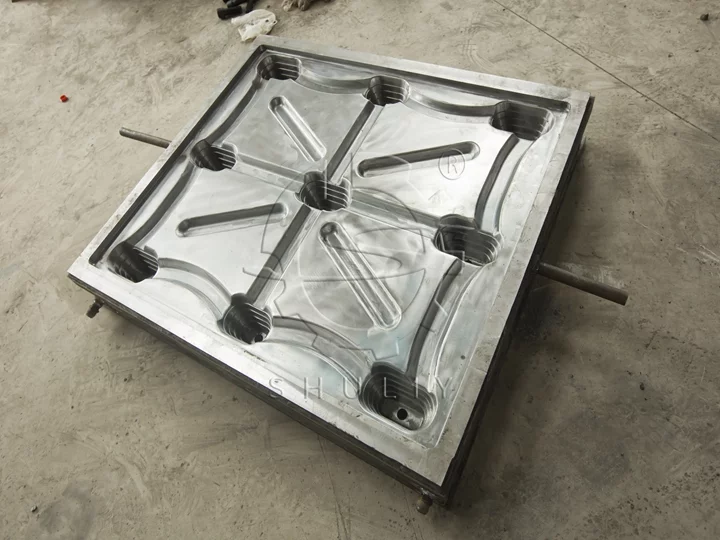

Setelah menilai kebutuhan spesifik klien, kami merekomendasikan Mesin Pembuat Palet Kayu berkinerja tinggi kami.

- Keluaran tinggi. Mampu memproduksi palet dalam jumlah besar per hari, memenuhi permintaan pelanggan yang terus meningkat.

- Manufaktur presisi. Mesin ini memastikan bahwa setiap palet memiliki ukuran, kekuatan, dan daya tahan yang seragam, sepenuhnya mematuhi standar industri.

- Otomatisasi yang efisien. Dengan fitur otomatisnya, alat berat ini hanya memerlukan sedikit intervensi manual, sehingga mengurangi biaya tenaga kerja dan meningkatkan produktivitas secara signifikan.

- Produksi berkelanjutan. Mesin kami dapat memproses bahan kayu daur ulang, memungkinkan klien mempertahankan praktik ramah lingkungan sekaligus mengurangi biaya bahan baku.

Instalasi dan pelatihan

Setelah alat berat tiba di Senegal, tim kami memberikan dukungan pemasangan yang komprehensif dan pelatihan langsung untuk staf pelanggan. Hal ini memastikan kelancaran transisi dari produksi manual ke operasi otomatis.

Klien dengan cepat beradaptasi dengan sistem baru, sehingga mereka dapat meningkatkan kapasitas produksi dengan segera.

Peningkatan produksi dan efisiensi biaya

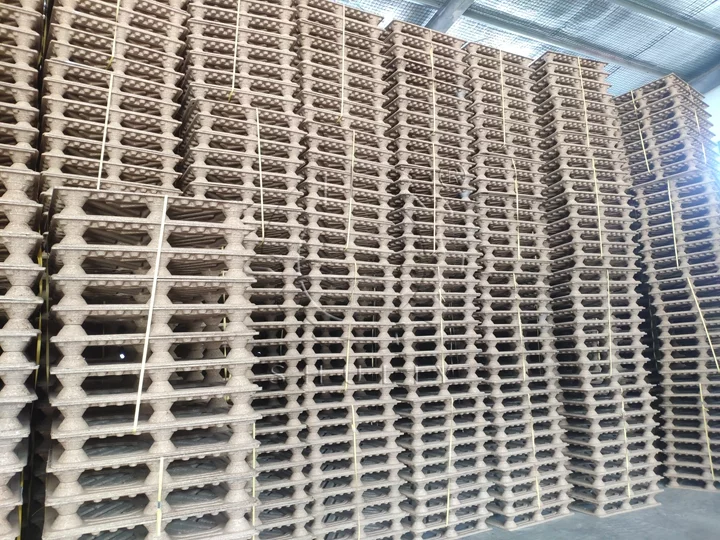

Setelah pemasangan Mesin Pembuat Palet Kayu, pelanggan mengalami peningkatan yang signifikan baik dalam kapasitas produksi maupun efisiensi biaya.

Sistem otomatis memungkinkan pengurangan biaya tenaga kerja secara drastis, sementara kemampuan menggunakan bahan daur ulang membantu menurunkan biaya bahan baku.

Yang terpenting, kualitas palet yang konsisten memenuhi permintaan klien mereka yang terus meningkat di berbagai industri.

Kesimpulan

Proyek ini menunjukkan bagaimana Mesin Pembuat Palet Kayu kami secara efektif mengatasi kebutuhan spesifik dari bisnis yang berkembang pesat di Senegal.

Dengan memberikan solusi yang meningkatkan kapasitas produksi, meningkatkan efisiensi, dan mendorong keberlanjutan, kami membantu pelanggan mengembangkan bisnisnya dan memenuhi permintaan pasar mereka.

Kami berharap dapat terus memberikan solusi mesin berkualitas tinggi yang dapat disesuaikan dengan kebutuhan bisnis di seluruh dunia.