Các tính năng trong nháy mắt

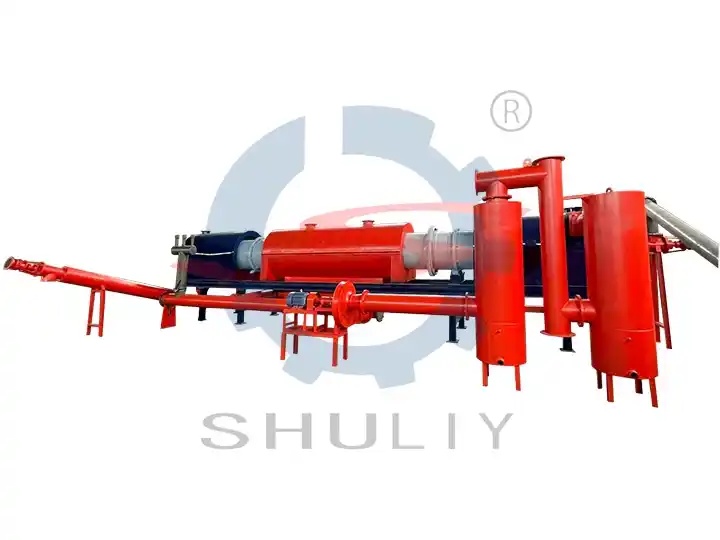

Lò Carbon Hóa Liên Tục được thiết kế để sản xuất than chất lượng cao trên quy mô lớn từ nhiều loại vật liệu sinh khối khác nhau, bao gồm vỏ trấu, gáo dừa, dăm gỗ, mùn cưa, và các vật liệu tương tự khác.

Với công suất 400-2000kg/h, nó hoạt động ở điều kiện nhiệt độ cao để thực hiện quá trình chưng cất khô, không có oxy, mang lại tỷ lệ carbon hóa cao cho các vật liệu như rơm, vỏ hạt cọ, và mảnh tre.

Điều này làm cho lò cacbon hóa liên tục trở thành một giải pháp lý tưởng cho các doanh nghiệp tìm cách sản xuất than bền vững một cách hiệu quả.

Lò cacbon hóa liên tục để bán

Lò carbon hóa liên tục bao gồm một hệ thống cấp liệu bằng vít, cấp liệu ngang, trống quay, xả ngưng tụ, bộ đốt, buồng đốt, bộ phận lọc khí và tủ điều khiển.

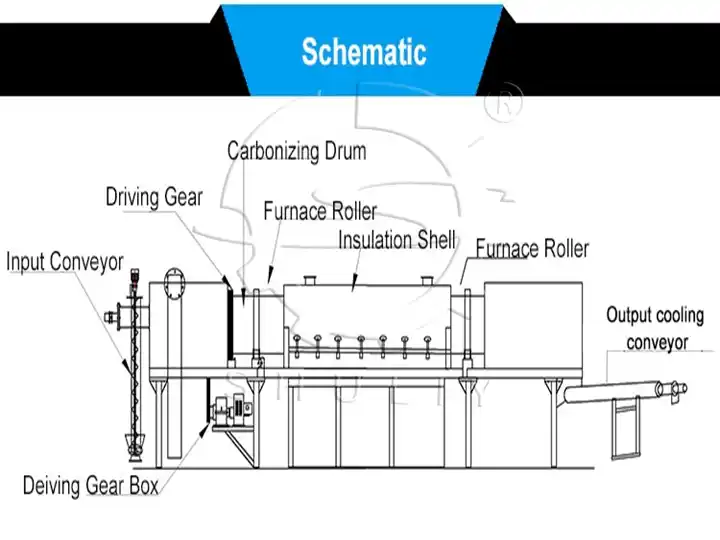

Sơ đồ của lò carbon hóa liên tục

Trưng bày các thành phần chính

- Carbonat. Đơn vị cốt lõi để chuyển đổi sinh khối thành than.

- Máy khí hóa. Tạo điều kiện cho việc sản xuất khí dễ cháy trong quá trình cacbon hóa.

- Bộ xử lý bồ hóng. Lọc ra tạp chất và ngăn chặn sự phát xạ của các hạt có hại.

- Máy lọc khí dễ cháy. Hủy bỏ các chất gây ô nhiễm khỏi khí để đảm bảo khí thải sạch.

- Ngưng tụ khí dễ cháy. Thu thập và ngưng tụ các khí để sử dụng thêm.

- Người hâm mộ dự thảo. Thúc đẩy lưu thông khí trong suốt hệ thống để duy trì hoạt động hiệu quả.

Lò carbon hóa liên tục được cấu thành từ nhiều thành phần chính hoạt động đồng bộ để sản xuất than chất lượng cao trong khi giảm thiểu tác động đến môi trường.

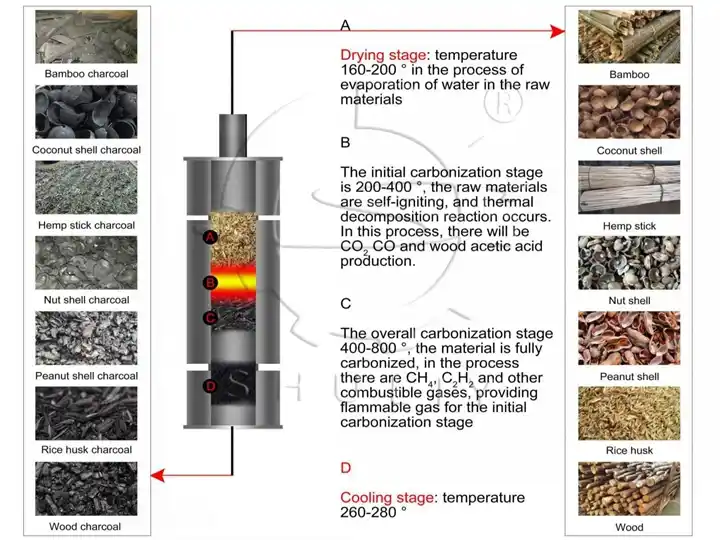

Quy trình sản xuất của lò carbon hóa liên tục

Lò cacbon hóa liên tục hoạt động bằng cách khai thác nhiệt được tạo ra từ quá trình đốt cháy để bắt đầu quá trình nhiệt phân của nguyên liệu sinh khối.

Khi vật liệu di chuyển qua trống quay, nó phải chịu nhiệt độ cao được kiểm soát cẩn thận, phá vỡ các hợp chất hữu cơ phức tạp và giải phóng khí dễ bay hơi.

Những khí này sau đó được đốt cháy trong buồng đốt, cải thiện đáng kể hiệu quả năng lượng của lò trong khi giảm thiểu khí thải có hại.

- Sử dụng nhiệt. Sử dụng nhiệt đốt để khởi động quá trình nhiệt phân của nguyên liệu sinh khối.

- Trống quay. Sinh khối di chuyển qua trống, đảm bảo tiếp xúc đồng đều với nhiệt độ cao.

- Phân tích hiệu quả. Nhiệt độ cao phân hủy các hợp chất hữu cơ và giải phóng khí dễ bay hơi.

- Tối đa hóa năng lượng. Khí dễ bay hơi được đốt trong buồng đốt để sử dụng năng lượng tối ưu.

- Giảm phát thảiNhựa gỗ và giấm gỗ được tạo ra trong quá trình sản xuất được đốt cháy, đảm bảo không gây ô nhiễm môi trường. Nước có thể tái chế, giúp tiết kiệm và bảo tồn tài nguyên nước.

Đặc điểm kỹ thuật của lò cacbon hóa liên tục

Lò carbon hóa liên tục bán chạy:

| Người mẫu | SL-CF800 | SL-CF1000 | SL-CF1200 |

| Đường kính (mm) | 800 | 1000 | 1200 |

| Công suất (kg / giờ) | 400-600 | 800-1000 | 1200-2000 |

| Công suất chính (kw) | 18.5 | 18.5 | 20 |

| Nhiệt độ cacbon hóa (oC) | 500-800 | 500-800 | 500-800 |

| Công suất quạt (kw) | 5.5 | 5.5 | 5.5 |

Chúng tôi hỗ trợ dịch vụ tùy chỉnh. Nếu bạn muốn tìm hiểu thêm về các mẫu và chi tiết sản phẩm của chúng tôi, xin vui lòng liên hệ với chúng tôi!

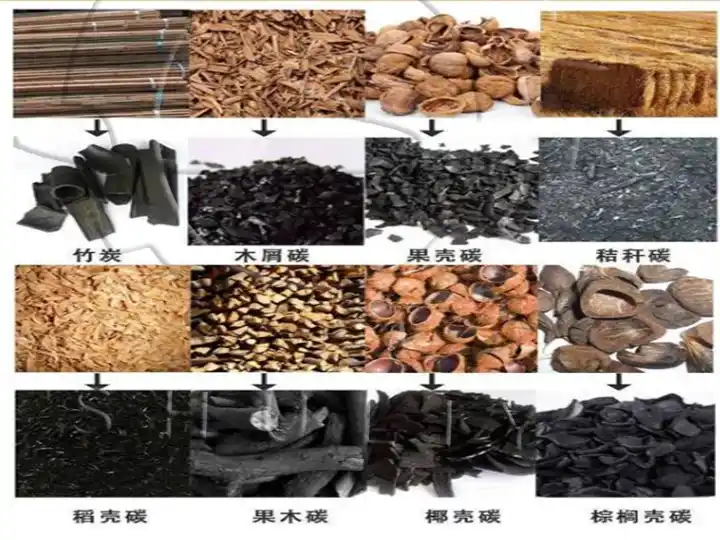

Những vật liệu nào phù hợp cho máy làm than cưa?

Máy làm than cưa có khả năng xử lý nhiều loại nguyên liệu thô, làm cho nó rất linh hoạt.

Nó có thể xử lý sinh khối, bùn, rác thải và các vật liệu khác, miễn là kích thước của chúng dưới 15 cm và độ ẩm dưới 15%.

Những vật liệu này có thể được cacbon hóa trực tiếp, cho phép sản xuất than hiệu quả và bền vững.

- Vật liệu sinh khối (ví dụ: mùn cưa, vỏ đậu phộng, thân ngô và vỏ gạo)

- Dư lượng nông nghiệp (ví dụ: bã mía, thân cây lúa miến và thân cây bông)

- Chất thải lâm nghiệp (ví dụ: chip tre, cành và vỏ cọ)

- Chất thải hữu cơ khác (ví dụ: hạt chưng cất, hạt ngô và lá chết)

- Sản phẩm phụ từ các ngành công nghiệp khác nhau (ví dụ: bã cà phê, vỏ quả mơ và dư lượng y học cổ truyền Trung Quốc)

- Các thân cây khác nhau (ví dụ: trấu hạt hướng dương, cỏ khoai mỡ và thân cây gai dầu)

Những vật liệu này đều có thể được xử lý hiệu quả trong lò cacbon hóa liên tục để sản xuất than chất lượng cao.

Ưu điểm của lò cacbon hóa liên tục

- Hiệu quả cao. Cho phép hoạt động liên tục, tăng năng suất bằng cách loại bỏ tải và dỡ hàng thường xuyên.

- Đầu ra nhất quán. Đảm bảo cacbon hóa đồng đều, dẫn đến chất lượng nhất quán của than cuối cùng.

- Hiệu quả năng lượng. Sử dụng các hệ thống thu hồi nhiệt để tái chế khí thải và nhiệt thải, giảm mức tiêu thụ năng lượng.

- Linh hoạt. Thích nghi với các nguyên liệu thô và cài đặt cacbon hóa khác nhau, như nhiệt độ, thời gian cư trú và tốc độ dòng khí.

- Kiểm soát tự động. Tính năng tự động hóa nâng cao để giám sát chính xác, tăng cường an toàn và giảm thiểu sự can thiệp của con người.

- Sự thân thiện với môi trường. Kết hợp loại bỏ bụi và hệ thống kiểm soát khí thải để đáp ứng các tiêu chuẩn môi trường và giảm ô nhiễm.

- Tiết kiệm chi phí. Giảm chi phí lao động và năng lượng, trong khi sản lượng chất lượng cao của nó giúp cải thiện khả năng cạnh tranh và lợi nhuận của thị trường.

Đặc điểm công nghệ của lò cacbon hóa liên tục

- Tự động hóa cao. Sản xuất dây chuyền lắp ráp với công nghệ tiên tiến để niêm phong nhiệt độ cao, cho phép cacbon hóa trong các môi trường khác nhau (chân không, áp suất dương, bảo vệ khí quyển, không có oxy).

- Điều chỉnh phạm vi nhiệt độ. Nhiệt độ có thể được kiểm soát chính xác từ 50-1000 ° C để đáp ứng các yêu cầu sản phẩm cụ thể.

- Hoạt động áp lực bình thường. Đảm bảo điều kiện hoạt động vượt trội với bụi tối thiểu trong hội thảo.

- Khối lượng không khí thấp. Giảm áp lực lên hệ thống thu thập bụi bằng cách yêu cầu thể tích không khí tối thiểu.

- Thời gian bắn có kiểm soát. Thời gian bắn có thể được điều chỉnh để đảm bảo cacbon hóa đồng đều và kỹ lưỡng.

- Tái chế năng lượng. Tái chế năng lượng nhiệt toàn diện giúp tăng cường hiệu quả sử dụng năng lượng nhiệt.

- Nhiều vùng nhiệt độ. Xi lanh bên trong có thể có nhiều vùng để kiểm soát nhiệt độ dựa trên các đặc tính sản phẩm.

- Phục hồi dung môi. Thuận tiện cho sự phục hồi của dung môi từ vật liệu.

- Tỷ lệ vật liệu lấp đầy cao. Đạt được hơn 15% Tốc độ vật liệu để trao đổi nhiệt tối ưu với khí thải nóng, với tốc độ tối đa là 25%.

Làm thế nào để máy làm than cưa hoạt động?

- Cơ chế làm lệch hướng. Nguyên liệu thô xâm nhập vào lò chính cacbon hóa và di chuyển theo chiều ngang với vòng quay của lò, được hướng dẫn bởi bộ lệch.

- Cacbon hóa liên tục. Các vật liệu dần dần chuyển từ đầu vào thức ăn sang ổ cắm carbon trong khi trải qua quá trình cacbon hóa trong quá trình di chuyển của nó.

- Khóa không khí. Cả hai cửa hàng thức ăn và carbon đều được trang bị khóa không khí để ngăn không khí xâm nhập, duy trì môi trường nghèo oxy.

- Gây ra người hâm mộ dự thảo. Lò chính được trang bị quạt dự thảo cảm ứng để duy trì bầu không khí nghèo oxy trong quá trình cho ăn và cacbon hóa liên tục.

- Hoạt động liên tục. Thiết kế cho phép cho ăn và cacbon hóa liên tục, tăng cường hiệu quả và năng lực sản xuất.

- Cải thiện kết quả cacbon hóa. Môi trường nghèo oxy đảm bảo chất lượng cacbon hóa tốt hơn và lý tưởng để sản xuất than củi và tre.

Các trường hợp của khách hàng trong lò cacbon hóa liên tục

Trong một câu chuyện thành công đáng chú ý, một khách hàng đến từ Congo đã đặt hàng lò cacbon hóa liên tục và máy nghiền than từ Nhà máy Shuliy.

Với công suất đầu ra ấn tượng 800-1000kg/h, những chiếc máy này được lựa chọn đặc biệt để tạo điều kiện thuận lợi cho việc sản xuất và bán than nướng chất lượng cao.

Liên hệ với chúng tôi

Tóm lại, Lò Carbon Hóa Liên Tục là một minh chứng cho sự đổi mới trong lĩnh vực sản xuất than bền vững. Quy trình liên tục, chuyển đổi sinh khối hiệu quả và hoạt động thân thiện với môi trường khiến nó trở thành một tài sản không thể thiếu cho các ngành công nghiệp tìm kiếm các phương pháp thực hành xanh hơn.

Ngoài ra, chúng tôi tự hào cung cấp hai mẫu lò carbon hóa khác: Lò Carbon Hóa Nâng và Lò Carbon Hóa Ngang.

Mỗi mô hình cung cấp các tính năng độc đáo để đáp ứng nhu cầu đa dạng trong sản xuất than củi và các giải pháp năng lượng bền vững. Khám phá các loại lò cacbon hóa của chúng tôi và cách mạng hóa phương pháp sản xuất than củi của bạn ngay hôm nay.

Lò Carbonization liên tục SL-CF1200 được vận chuyển thành công đến Vương quốc Anh

Vào tháng 3 năm 2025, một công ty có trụ sở tại Vương quốc Anh tập trung vào phục hồi thiên nhiên…

Sản phẩm hot

Máy đóng gói phim co nhiệt | Máy đóng gói viên than

Máy đóng gói phim co nhiệt của chúng tôi, còn được gọi là…

Máy băm gỗ kiểu trống

Máy băm gỗ kiểu trống được sử dụng trong…

Máy sấy lưới băng tải cho viên nén than

Máy sấy băng tải lưới, còn được gọi là…

Máy Trộn Than | Máy Trộn Bột Than

Máy trộn than này cũng có thể được gọi là...

Máy làm than BBQ | Máy ép viên than

Máy sản xuất than BBQ có thể ép các vật liệu dạng bột,...

Máy ép viên than | Máy ép viên than tổ ong

Máy ép viên than có thể tạo ra các hình dạng khác nhau và…

Lò carbon hóa đứng cho việc sản xuất than từ gỗ cứng

Lò cacbon hóa đứng này có thể được sử dụng cho…

Lò carbon hóa liên tục | Máy làm than từ mùn cưa

Lò cacbon hóa liên tục dùng cho quy mô lớn…

Máy sấy vỏ rơm | Máy sấy quay để bán

Máy sấy trấu của chúng tôi, hay máy quay...