什么是水平木炭炉以及它是如何工作的?

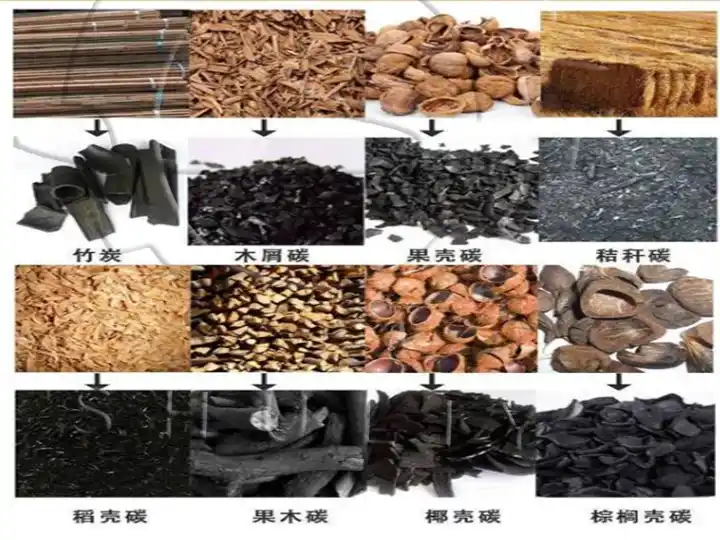

水平木炭炉是一种将木材、竹材或农业和林业废弃物转化为木炭的装置。在众多炭化机中,它由于结构合理、操作简便、炭化效果稳定而被广泛应用于工业和家庭木炭生产。

什么是水平木炭炉?

水平木炭炉是一种水平放置的炭化装置。炉体为水平结构:原料从前端进入炉腔,成炭从另一端排出。与竖直木炭炉相比,其优点是:

- 扁平炉腔,材料铺开面积大

- 均匀的热分布,确保良好的炭化效果

- 易装载/卸料,省人工

- 结构紧凑,运行安全

水平木炭炉的工作原理

水平木炭炉的核心工作原理是热解炭化。

装载中

在炉腔中将原料均匀铺开。层厚保持适中,避免因太密而影响传热的区域。

外部加热与点火

炉子有外部燃烧室,可使用木材、煤气或回收的炭化气作为热源。点火后,炉温逐渐上升,原料开始分解。

炭化过程

在低氧条件下,高温驱出木材中的水分、树脂和挥发物。

在早期产生的一氧化碳和甲烷等气体被重新燃烧,提供内部热量,节省能源,同时环保。

冷却与排出

炭化后,控制炉温,让木炭缓慢冷却,防止自燃。

最后,从排放口取出木炭,获得优质木炭。

温度控制 – 椰子壳木炭示例

椰子壳是一种硬质、高密度的生物质材料,其炭化需要精准的温度控制。水平木炭炉通过适当的温度管理能够确保高质量、高产量的椰子壳木炭。

炭化温度阶段

1. 脱水阶段(100℃–200℃)

- 目的: 去除椰壳中的水分,防止炭化过程中产生烟雾或裂纹。

- 控制方法: 缓慢升温,避免表面焦黑或不均匀炭化。

2.热解阶段(250℃–450℃)

- 目的: 椰壳中的挥发物分解,产生可燃气体,形成木炭骨架。

- 控制方法: 保持稳定加热和低氧环境,防止燃烧而非炭化。

3. 炭化阶段(450℃–600℃)

- 目的: 完成炭化,生产高硬度、低灰分、燃烧稳定的木炭。

- 控制方法: 保持高温一段时间,然后逐渐冷却,使木炭密实,防止自燃。

椰子壳木炭的炭化结果

在精确的温度控制下,椰子壳木炭具备以下特征:

- 高密度: 燃烧时间长,适用于工业和烧烤

- 灰分低: 燃烧干净,减少污染

- 燃烧稳定: 均匀加热,烟雾少

- 密实木炭: 触感坚硬,不易破碎

水平木炭炉的温控方法

- 外部燃烧室调节: 使用柴火、煤气或炭化气作为燃料。通过调节燃料量和通风口控制炉温。

- 炉腔通风: 调整通风口或空气入口,控制进入的空气量,确保低氧环境和稳定的温度。

- 温度监测系统: 先进的水平炭化炉可以配备温度传感器和PLC控制系统,实现自动温度调节,提高炭化的均匀性和效率。

应用领域

- 工业木炭生产:用于冶炼、烧烤和化工原料木炭生产。

- 家庭炭化:小型水平木炭炉适合农民或家庭使用。

- 农业废弃物处理:把秸秆和果壳转化为高价值木炭,减少环境污染。

水平木炭炉型号推荐

| 模型 | 容量 | 机器重量 | 尺寸(L×W×H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg/12–14小时 | 2500公斤 | 3×1.7×2.2米 |

| SL-1500 | 1500–2000 kg/12–14小时 | 4000公斤 | 4.5×1.9×2.3米 |

| SL-1900 | 2500–3000 kg/12–14小时 | 5500公斤 | 5×2.3×2.5米 |

水平木炭炉可以用于哪些生产?

以下文章将帮助您更好地理解水平木炭炉在生产过程中的作用。