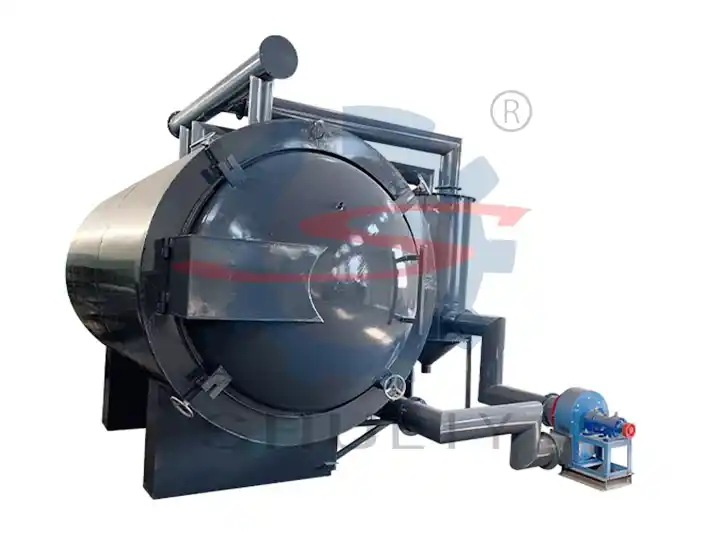

Four à charbon horizontal pour la production de biochar

Machine de fabrication de charbon de bois horizontale | Four à charbon de bois

Four à charbon horizontal pour la production de biochar

Machine de fabrication de charbon de bois horizontale | Four à charbon de bois

Aperçu des fonctionnalités

Le four horizontal au charbon de bois est un équipement haute performance conçu pour une carbonisation industrielle efficace et respectueuse de l'environnement. Doté d'une structure horizontale innovante, il intègre une technologie de contrôle de la température précise et un système de combustion d'économie d'énergie.

Avec une capacité de traitement quotidienne de 900 à 3000 kg (12-14 heures par lot), il répond aux besoins d'une production petite à grande à grande échelle. Cette fournaise est largement utilisée dans la production de charbon de bois de biomasse, la fabrication de carbone activée, le traitement thermique en métal et le traitement des matières premières chimiques.

Application du four horizontal au charbon de bois

Le four à charbon horizontal, également connu sous le nom de Four à charbon de bois ou machine de fabrication de charbon de bois horizontale, est une solution de carbonisation très polyvalente et efficace.

Conçu pour la production à l'échelle industrielle, il convertit divers matériaux de biomasse, tels que les copeaux de bois, la sciure de bois et les déchets agricoles - en charbon de bois ou biochar de haute qualité grâce à un processus de carbonisation contrôlé.

- Agriculture et foresterie - Utilisé pour traiter les résidus agricoles et forestiers dans le biochar pour l'amélioration du sol et la séquestration du carbone.

- Protection de l'environnement - Aide à réduire les déchets en convertissant la biomasse en charbon de bois respectueux de l'environnement, en soutenant des solutions énergétiques durables.

- Production commerciale de charbon de bois - Idéal pour les entreprises nécessitant une carbonisation à grande échelle et à haute efficacité pour produire du charbon de bois pour le carburant, le carbone activé ou les applications industrielles.

Pour répondre à divers besoins de carbonisation, nous offrons également fours de carbonisation continue, fours de carbonisation à flux d'air verticalet d'autres modèles spécialisés.

Comment fonctionne la machine de fabrication de charbon de bois horizontale?

- Chargement de la biomasse. Les matériaux de biomasse sont chargés dans le four horizontal au charbon de bois.

- Ignition et génération de chaleur. La fournaise est enflammée, générant de la chaleur dans la chambre et initiant le processus de carbonisation.

- Contrôle de la température. La température est généralement contrôlée à environ 600 ℃.

- Même le chauffage. La disposition horizontale garantit un chauffage uniforme des matériaux de biomasse.

- Libération de gaz et de volatiles. Des gaz évolués et des composants volatils sont libérés au cours de cette phase.

- Flux d'air contrôlé. Le flux d'air contrôlé est maintenu dans la fournaise horizontale.

- Retrait efficace. Cela garantit l'élimination efficace de l'humidité, des substances volatiles et d'autres impuretés des matériaux de biomasse.

- Transformation progressive. Les matériaux subissent une transformation progressive, se transformant en charbon de bois de haute qualité.

Avantages de la conception horizontale

- Flux d'air optimal. Il fournit également un flux d'air optimal, ce qui est crucial pour l'élimination efficace des impuretés et la production de charbon de bois de haute qualité.

- Distribution de la chaleur uniforme. La conception horizontale assure une distribution de chaleur uniforme tout au long du processus de carbonisation.

La machine horizontale de fabrication de charbon de bois exploite sa conception unique pour assurer une carbonisation efficace et la production de produits de charbon de bois supérieurs.

En maintenant un flux d'air contrôlé et une distribution de chaleur uniforme, il facilite la transformation progressive des matériaux de biomasse en charbon de bois de haute qualité.

Processus de carbonisation dans le four à charbon de bois en rondins

Le processus de carbonisation dans une fournaise en bois à bois suit une séquence structurée pour s'assurer Production de charbon de bois efficace et contrôlée. En utilisant un système bien conçu, la fournaise convertit efficacement les matières premières en charbon de bois de haute qualité grâce à un processus de combustion cyclique.

- Chargement des matières premières

- Sections de journal et branches sont soigneusement disposés dans un cadre en fer, qui est ensuite poussé en douceur dans la cavité du four à l'aide d'un piste de convoyeur.

- Alternativement, cocoes de noix de coco, branches cassées et autres matériaux de biomasse peut être directement chargé dans le furnace du four horizontal au charbon de bois.

- Sceller la fournaise

- Le Couverture du fours à charbon horizontal du flux d'air est fermement fermé.

- Toutes les lacunes près de la couverture sont scellé de boue ou d'isolation coton pour éviter les fuites d'air et assurer un environnement étanche à l'air.

- Allumage et chauffage initial

- UN fournaise à gazéification est utilisé pour enflammer le carburant dans le port d'allumage au bas de la fournaise.

- Au fur et à mesure que le carburant brûle, la température à l'intérieur du four augmente progressivement.

- Surveillance de la température et de la circulation des gaz

- Le thermomètre à fournaise est surveillé étroitement. Lorsque la température atteint autour 400 ° C, le four à gazéification est désactivé.

- À ce stade, le gaz combustible produit à l'intérieur du four à carbonisation subit combustion cyclique, Réduire le besoin de carburant externe.

- Carbonisation finale et formation de charbon de bois

- Le processus de chauffage soigneusement réglementé garantit transformation efficace de matières premières dans charbon de bois de haute qualité.

- Le contrôlé flux d'air et distribution de chaleur contribuer à un processus de carbonisation cohérent et efficace.

En suivant ces étapes systématiques, le four à charbon de bois maximise efficacité énergétique, minimise déchetset assure Production de charbon de bois à haut rendement, ce qui en fait une solution idéale pour les besoins de carbonisation commerciale.

Paramètre du four horizontal au charbon de bois

| Modèle | Capacité | Poids de la machine | Dimensions (L × W × H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg / 12–14 heures | 2500 kg | 3 × 1,7 × 2,2 mètres |

| SL-1500 | 1500–2000 kg / 12–14 heures | 4000 kg | 4,5 × 1,9 × 2,3 mètres |

| SL-1900 | 2500–3000 kg / 12–14 heures | 5500 kg | 5 × 2,3 × 2,5 mètres |

Structure du four horizontal au charbon de bois

Isolation thermique améliorée

- Les surfaces rocheuses d'isolation thermique très efficaces sont intégrées dans le couvercle et le corps de la fournaise, garantissant une rétention de chaleur supérieure.

- La conception avancée d'étanchéité améliore l'isolation thermique, empêchant la perte de chaleur pendant le processus de carbonisation.

- La construction optimisée des fournais maintient des températures internes stables, améliorant l'efficacité énergétique globale.

Circulation efficace des gaz de combustion

- Un réseau de tuyaux est intégré dans le four, reliant les sections supérieures et inférieures pour optimiser le débit de gaz.

- Les tuyaux en circulation facilitent le mouvement du gaz combustible dans le cylindre, améliorant l'efficacité énergétique.

- Des tuyaux supplémentaires sont conçus pour filtrer les gaz de combustion, améliorant les performances environnementales du four.

Système de chariot pratique

- Les systèmes de chariot sont inclus pour faciliter le transport des matières premières et du charbon de bois fini.

- Conçu pour gérer la capacité substantielle du four et la puissance élevée, assurant un fonctionnement en douceur.

- Améliore l'efficacité globale et la commodité, réduisant l'intensité de la main-d'œuvre pour les opérateurs.

Caractéristiques de la machine à fabrication de charbon de bois horizontal

- Corps de four à trois couches. Le corps de la fournaise est construit avec trois couches, et la porte est doublée d'un coton ignifuge et issu de la flamme, assurant une excellente étanchéité de l'air, une rétention thermique et une efficacité énergétique tout en réduisant la consommation de carburant.

- Système de récupération de gaz de combustion. La technologie intégrée de récupération des gaz de combustion améliore l'efficacité énergétique, minimisant les déchets de ressources.

- Conception de la voiture au four. La voiture de four à mobile simplifie le fonctionnement, réduisant l'intensité du travail et rendant le chargement et le déchargement plus pratique.

- Haute capacité et carbonisation unique. La machine peut accueillir de grandes charges de matériaux, permettant une carbonisation efficace par lots.

- Plusieurs options de chauffage. Compatible avec diverses sources de carburant, y compris le bois, le charbon et le gaz naturel, offrant une flexibilité en fonction de la disponibilité et du coût.

- Émissions sans fumée. Un système de purification des gaz de combustion à haute performance garantit un fonctionnement respectueux de l'environnement avec un minimum d'émissions de fumée.

- Système de refroidissement par eau. Un système de refroidissement rapide accélère le processus, améliorant l'efficacité globale et la productivité.

Contactez-nous

Si vous êtes intéressé par notre produit et souhaitez en savoir plus ou demander un devis, n’hésitez pas à nous contacter.

Notre équipe professionnelle se consacre à vous fournir un soutien et une assistance pour vous aider à atteindre vos objectifs de production de charbon de bois. Agissez maintenant et rejoignez-nous pour façonner l'avenir de durable charbon production!

Produit chaud

Machine de séchage de briquettes de charbon de bois en boîte

Cette machine à sécher les briquettes de charbon de bois est un…

Machine à palettes en bois comprimé pour palettes en bois pressé

Notre machine à palettes en bois compressé est conçue pour…

Machine de fabrication de briquettes de sciure de bois | Machine à briquettes de biomasse

La machine de fabrication de briquettes de sciure de bois est une solution écologique…

Machine à charbon de chicha pour charbon de narguilé rond et cubique

Notre populaire machine à charbon de chicha peut produire des produits de haute qualité…

Déchiqueteuse à bois à disque | Machine de fabrication de copeaux de bois

La déchiqueteuse à bois à disque constitue une solution polyvalente…

Mélangeur de charbon de bois | Mélangeur de poudre de charbon de bois

Ce mélangeur à charbon de bois peut également être nommé…

Four de carbonisation vertical pour la fabrication de charbon de bois dur

Ce four de carbonisation vertical peut être utilisé pour…

Machine de fabrication de blocs de palettes en bois

La machine de fabrication de blocs de palettes en bois utilise de la sciure de bois et…

Machine à granulés d'alimentation animale | Machine de broyeur d'aliments pour granulés

Shuliy propose la machine à granulés d'aliments pour animaux pour…