Broyeur de bois pour entreprises envoyé en Pologne

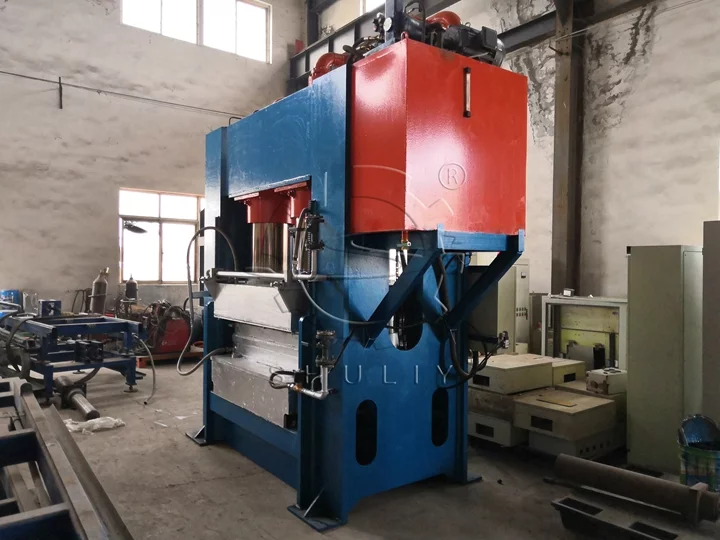

We are pleased to present a successful case study involving the sale of our SL-600 wood crusher machine to a customer in Poland.

Cette collaboration souligne notre engagement à fournir des équipements performants et adaptés aux besoins spécifiques de nos clients de l’industrie de la transformation du bois.

Exigences des clients pour la machine de concassage de bois

Lors de nos premières discussions, le client a souligné plusieurs exigences critiques :

- Spécifications du modèle. Ils étaient intéressés par le modèle SL-600, doté d'une capacité de traitement de 800 à 1 000 kg/h, propulsé par un moteur robuste de 30 kW et capable de traiter des matières premières jusqu'à 17 cm de diamètre.

- Transformation polyvalente des matières premières. La machine devait traiter efficacement divers types de bois, notamment des bûches, des branches, des chutes de bois et des palettes de bois. La capacité à gérer des matériaux issus de la biomasse tels que le bambou et les résidus agricoles était également cruciale.

- Haute efficacité et fiabilité. Le client recherchait une machine fiable, capable de fournir un rendement constant et de résister à une utilisation intensive.

Défis rencontrés

Au cours du processus d'achat, le client a rencontré plusieurs défis :

- Polyvalence des matériaux. Ils se demandaient si le SL-600 pouvait gérer efficacement une large gamme de matières premières, y compris les options en bois et non ligneuses.

- Comprendre le principe de fonctionnement. Le client souhaitait des informations détaillées sur le fonctionnement de la machine, notamment sur ses capacités de concassage.

- Soutien opérationnel. S'assurer que leur équipe puisse faire fonctionner la machine sans temps d'arrêt fréquent était une priorité.

Nos solutions

Pour relever ces défis, nous avons mis en œuvre des solutions ciblées :

- Démonstration de manutention. Nous avons organisé une démonstration en direct montrant la capacité du SL-600 à traiter différents matériaux. Cela a démontré la polyvalence de la machine dans la manipulation de grumes, de branches et de résidus agricoles.

- Explication détaillée du principe de fonctionnement. Nous avons fourni un aperçu complet du fonctionnement du SL-600. La machine comprend une trémie d'alimentation dans laquelle les matières premières entrent, et à l'intérieur de la chambre de concassage, des lames rotatives et des marteaux travaillent ensemble pour réduire les matériaux en particules plus petites, obtenant ainsi un concassage efficace par cisaillement et impact.

- Formation et assistance complètes. Nous avons organisé des sessions de formation pour le personnel du client, couvrant les meilleures pratiques d’exploitation et de maintenance. Cela a permis à leur équipe de se sentir en confiance dans l’utilisation efficace de la machine.

Avantages du broyeur à bois SL-600

Le broyeur à bois SL-600 a apporté des avantages significatifs à notre client polonais :

- Traitement amélioré des matériaux. La capacité impressionnante du SL-600 de 800 à 1 000 kg/h permet un traitement efficace de diverses matières premières, notamment les bûches et la biomasse, rationalisant ainsi leurs opérations.

- Efficacité accrue. La combinaison d'un puissant moteur de 30 kW et de la capacité de manipuler des matériaux jusqu'à 17 cm de diamètre signifie un traitement plus rapide et des coûts d'exploitation réduits.

- Durabilité et économies de coûts. Conçu pour résister à une utilisation intensive, le SL-600 s'est avéré être un atout fiable, réduisant les besoins de maintenance et les coûts globaux pour le client.

Conclusion

Notre collaboration avec le client polonais met en évidence notre capacité à répondre aux exigences spécifiques du secteur de la transformation du bois.

En fournissant le broyeur à bois SL-600, nous avons non seulement répondu à leurs besoins en matière de traitement efficace et polyvalent, mais nous les avons également positionnés pour une croissance et un succès futurs dans leurs opérations.

Nous sommes impatients de les soutenir à mesure qu’ils développent davantage leurs capacités.