Tungku Karbonisasi Berkelanjutan | Mesin Pembuat Arang Serbuk Gergaji

Tungku karbonisasi biomassa

Tungku Karbonisasi Berkelanjutan | Mesin Pembuat Arang Serbuk Gergaji

Tungku karbonisasi biomassa

Sekilas Fitur

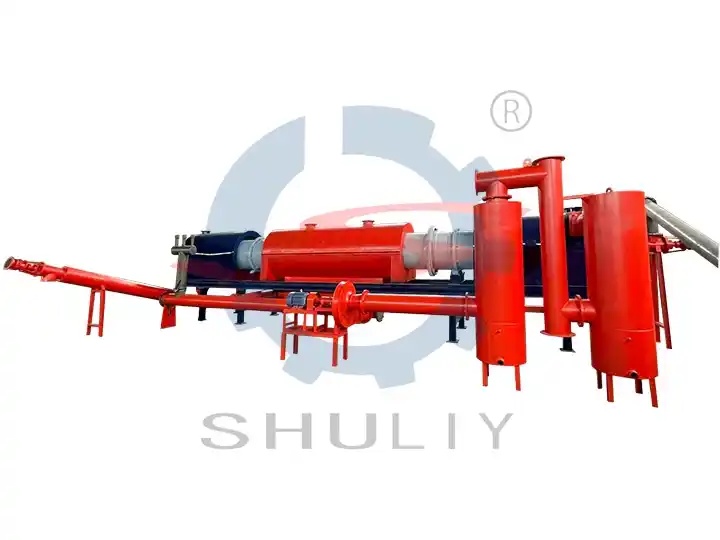

Tungku Karbonisasi Berkelanjutan dirancang untuk produksi arang berkualitas tinggi dalam skala besar dari berbagai bahan biomassa, termasuk sekam padi, tempurung kelapa, serpihan kayu, serbuk gergaji, dan bahan serupa lainnya.

Dengan kapasitas 400-2000kg/jam, alat ini beroperasi pada kondisi suhu tinggi untuk mencapai distilasi kering tanpa oksigen, menghasilkan tingkat karbonisasi tinggi untuk bahan seperti jerami, tempurung inti sawit, dan potongan bambu.

Ini menjadikan tungku karbonisasi berkelanjutan solusi ideal untuk bisnis yang ingin menghasilkan arang berkelanjutan secara efisien.

Tungku Karbonisasi Berkelanjutan Dijual

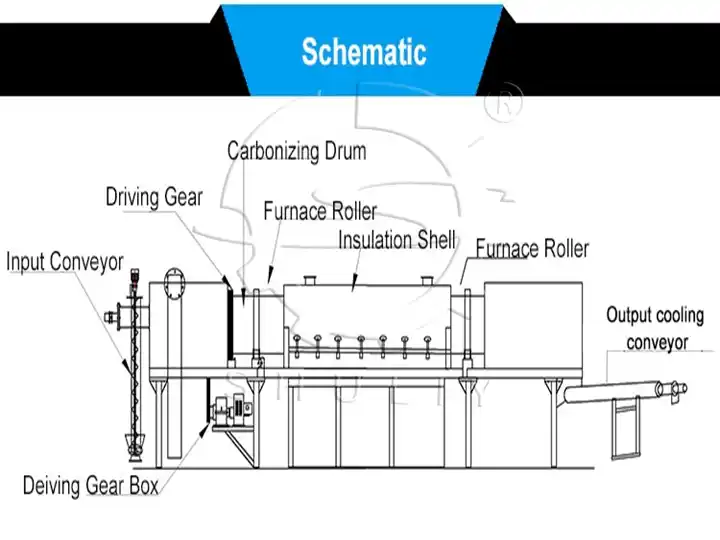

Tungku karbonisasi berkelanjutan terdiri dari sistem pengumpanan sekrup, pengumpanan horizontal, drum putar, pembuangan kondensasi, pembakar, ruang pembakaran, unit pemurnian, dan kabinet kontrol.

Skema dari tungku karbonisasi kontinu

Pameran komponen inti

- Karbonis. Unit inti untuk mengubah biomassa menjadi arang.

- Gasifier. Memfasilitasi produksi gas yang mudah terbakar selama proses karbonisasi.

- Prosesor jelaga. Menyaring kotoran dan mencegah emisi partikel berbahaya.

- Pembersih gas yang mudah terbakar. Lepaskan kontaminan dari gas untuk memastikan emisi yang bersih.

- Kondensor gas yang mudah terbakar. Mengumpulkan dan memadatkan gas untuk digunakan lebih lanjut.

- Penggemar draft yang diinduksi. Mempromosikan sirkulasi gas di seluruh sistem untuk mempertahankan operasi yang efisien.

Kuil karbonisasi kontinu terdiri dari beberapa komponen kunci yang bekerja secara sinergis untuk memproduksi arang berkualitas tinggi sambil meminimalkan dampak lingkungan.

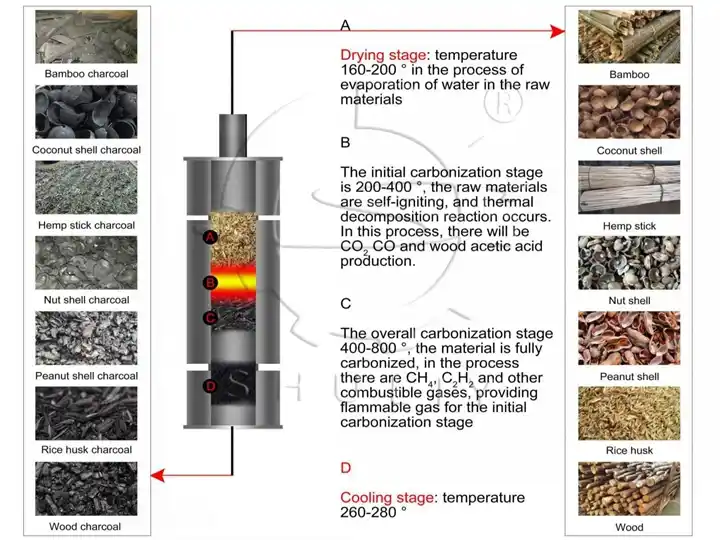

Proses produksi dari tungku karbonisasi kontinu

Tungku karbonisasi kontinu beroperasi dengan memanfaatkan panas yang dihasilkan dari proses pembakaran untuk memulai pirolisis bahan baku biomassa.

Ketika bahan bergerak melalui drum yang berputar, ia mengalami suhu tinggi yang dikendalikan dengan cermat, yang memecah senyawa organik yang kompleks dan melepaskan gas yang mudah menguap.

Gas -gas ini kemudian dibakar di ruang pembakaran, secara signifikan meningkatkan efisiensi energi tungku sambil meminimalkan emisi berbahaya.

- Pemanfaatan panas. Menggunakan panas pembakaran untuk memulai pirolisis bahan baku biomassa.

- Drum berputar. Biomassa bergerak melalui drum, memastikan paparan yang merata terhadap suhu tinggi.

- Pemisahan yang efisien. Suhu tinggi memecah senyawa organik dan melepaskan gas volatil.

- Maksimalisasi energi. Gas volatil dibakar di ruang pembakaran untuk penggunaan energi yang optimal.

- Pengurangan emisiTar kayu dan cuka kayu yang dihasilkan selama proses produksi dibakar, memastikan tidak ada pencemaran lingkungan. Air dapat didaur ulang, membantu menghemat dan melestarikan sumber daya air.

Spesifikasi tungku karbonisasi kontinyu

Furnace karbonisasi kontinu yang laris:

| Model | SL-CF800 | SL-CF1000 | SL-CF1200 |

| Diameter (mm) | 800 | 1000 | 1200 |

| Kapasitas (kg/jam) | 400-600 | 800-1000 | 1200-2000 |

| Kekuatan Utama (kw) | 18.5 | 18.5 | 20 |

| Suhu Karbonisasi (℃) | 500-800 | 500-800 | 500-800 |

| Kekuatan Kipas (kw) | 5.5 | 5.5 | 5.5 |

Kami mendukung layanan kustomisasi. Jika Anda ingin mengetahui lebih lanjut tentang model dan detail produk kami, silakan hubungi kami!

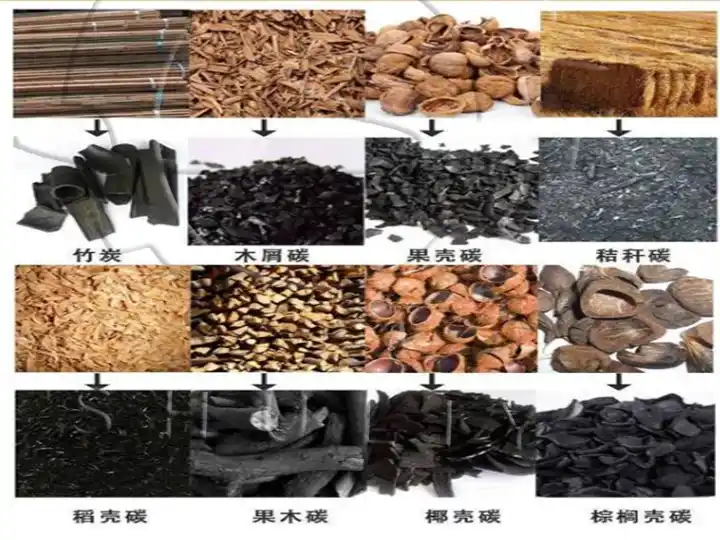

Bahan apa yang cocok untuk mesin pembuat arang serbuk gergaji?

Mesin pembuat arang serbuk gergaji mampu memproses berbagai bahan baku, membuatnya sangat fleksibel.

Dapat menangani biomassa, lumpur, sampah, dan bahan lainnya, asalkan ukurannya di bawah 15 cm dan kadar air di bawah 15%.

Bahan -bahan ini dapat secara langsung berkarbonisasi, memungkinkan produksi arang yang efisien dan berkelanjutan.

- Bahan biomassa (mis., Gergaji, kerang kacang, batang jagung, dan sekam padi)

- Residu pertanian (mis., Basi, tangkai sorgum, dan tangkai kapas)

- Limbah kehutanan (mis., Keripik bambu, cabang, dan cangkang palem)

- Limbah organik lainnya (mis., Biji -bijian penyuling, tepung jagung, dan daun mati)

- Produk sampingan dari berbagai industri (mis., Tempat kopi, sekam aprikot, dan residu obat tradisional Tiongkok)

- Berbagai batang tanaman (mis., Sekam biji bunga matahari, rumput ubi, dan batang rami)

Semua bahan ini dapat diproses secara efisien di tungku karbonisasi kontinu untuk menghasilkan arang berkualitas tinggi.

Keuntungan dari tungku karbonisasi berkelanjutan

- Efisiensi tinggi. Mengaktifkan operasi berkelanjutan, meningkatkan produktivitas dengan menghilangkan pemuatan dan pembongkaran yang sering.

- Output yang konsisten. Memastikan karbonisasi yang seragam, menghasilkan kualitas yang konsisten dari arang akhir.

- Efisiensi Energi. Memanfaatkan sistem pemulihan panas untuk mendaur ulang gas buang dan limbah panas, mengurangi konsumsi energi.

- Fleksibilitas. Beradaptasi dengan berbagai bahan baku dan pengaturan karbonisasi, seperti suhu, waktu tinggal, dan laju aliran gas.

- Kontrol otomatis. Fitur otomatisasi canggih untuk pemantauan yang tepat, meningkatkan keselamatan dan meminimalkan intervensi manusia.

- Keramahan lingkungan. Memasukkan sistem kontrol debu dan emisi untuk memenuhi standar lingkungan dan mengurangi polusi.

- Penghematan biaya. Mengurangi biaya tenaga kerja dan energi, sementara output berkualitas tinggi meningkatkan daya saing pasar dan profitabilitas.

Fitur Teknologi Tungku Karbonisasi Berkelanjutan

- Otomatisasi tinggi. Produksi jalur perakitan dengan teknologi canggih untuk penyegelan suhu tinggi, memungkinkan karbonisasi di berbagai lingkungan (vakum, tekanan positif, perlindungan atmosfer, bebas oksigen).

- Kisaran suhu yang bisa disesuaikan. Suhu dapat dikontrol secara tepat dari 50-1000 ° C untuk memenuhi persyaratan produk tertentu.

- Operasi tekanan normal. Memastikan kondisi operasi yang unggul dengan debu minimal di bengkel.

- Volume udara rendah. Mengurangi tekanan pada sistem pengumpulan debu dengan membutuhkan volume udara minimal.

- Waktu tembak yang dikendalikan. Waktu tembak dapat disesuaikan untuk memastikan karbonisasi yang merata dan menyeluruh.

- Daur Ulang Energi. Daur ulang energi termal yang komprehensif meningkatkan efisiensi pemanfaatan energi termal.

- Beberapa zona suhu. Silinder dalam dapat memiliki beberapa zona untuk kontrol suhu berdasarkan karakteristik produk.

- Pemulihan pelarut. Nyaman untuk pemulihan pelarut dari material.

- Laju bahan pengisian tinggi. Mencapai lebih dari 15% pengisian laju bahan untuk pertukaran panas yang optimal dengan gas buang panas, dengan laju maksimum 25%.

Bagaimana cara kerja mesin pembuatan arang serbuk gergaji?

- Mekanisme deflektor. Bahan baku memasuki tungku utama karbonisasi dan bergerak secara horizontal dengan rotasi tungku, dipandu oleh deflektor.

- Karbonisasi berkelanjutan. Bahan secara bertahap bergerak dari saluran masuk pakan ke outlet karbon sambil menjalani karbonisasi selama pergerakannya.

- Kunci udara. Baik outlet pakan dan karbon dilengkapi dengan kunci udara untuk mencegah udara masuk, mempertahankan lingkungan miskin oksigen.

- Penggemar draft yang diinduksi. Tungku utama dilengkapi dengan kipas angin yang diinduksi untuk mempertahankan atmosfer miskin oksigen selama proses pemberian makan dan karbonisasi yang berkelanjutan.

- Operasi Berkelanjutan. Desain ini memungkinkan pemberian makan dan karbonisasi yang berkelanjutan, meningkatkan efisiensi dan kapasitas produksi.

- Peningkatan hasil karbonisasi. Lingkungan miskin oksigen memastikan kualitas karbonisasi yang lebih baik dan sangat ideal untuk menghasilkan arang arang dan bambu.

Kasus Pelanggan di Tungku Karbonisasi Berkelanjutan

Dalam kisah sukses yang luar biasa, seorang pelanggan dari Kongo memesan tungku karbonisasi berkelanjutan dan penggiling arang dari Pabrik Shuliy.

Dengan kapasitas keluaran yang mengesankan sebesar 800-1000kg/jam, mesin ini dipilih secara khusus untuk memfasilitasi produksi dan penjualan arang barbekyu berkualitas tinggi.

Hubungi kami

Sebagai kesimpulan, Tungku Karbonisasi Berkelanjutan berdiri sebagai mercusuar inovasi dalam ranah produksi arang berkelanjutan. Proses berkelanjutannya, konversi biomassa yang efisien, dan operasi yang ramah lingkungan menjadikannya aset yang sangat diperlukan bagi industri yang mencari praktik yang lebih hijau.

Selain itu, kami bangga menawarkan dua model tungku karbonisasi lainnya: Tungku Karbonisasi Hoist dan Tungku Karbonisasi Horizontal.

Setiap model menawarkan fitur unik untuk memenuhi beragam kebutuhan produksi arang dan solusi energi berkelanjutan. Jelajahi rangkaian tungku karbonisasi kami dan revolusi pendekatan Anda terhadap produksi arang sekarang juga.

Tungku Pirolisis Berkelanjutan SL-CF1200 Berhasil Dikirim ke Inggris

Pada bulan Maret 2025, sebuah perusahaan yang berbasis di Inggris yang berfokus pada restorasi alam…

Produk Panas

Mesin Serutan Kayu | Serutan Batang untuk Tempat Tidur Hewan

Mesin Serutan Kayu memotong dan memproses secara efisien…

Furnace Karbonisasi Kontinu | Mesin Pembuatan Arang Serbuk Kayu

Tungku Karbonisasi Kontinu ditujukan untuk produksi skala besar…

Pengering Jaring Sabuk untuk Briket Arang

Pengering sabuk jala, juga dikenal sebagai…

Mesin Pembuatan Blok Palet Kayu

Mesin pembuat balok palet kayu memanfaatkan serbuk gergaji dan…

Mesin Arang Shisha untuk Arang Hookah Bulat & Kubus

Mesin Arang Shisha populer kami dapat menghasilkan arang berkualitas tinggi…

Mesin Pencetak Briket Batubara | Mesin Tekan Batubara Honeycomb

Mesin briket batu bara dapat menghasilkan berbagai bentuk dan…

Tungku Arang Horizontal untuk Memproduksi Biochar

Tungku Arang Horizontal adalah peralatan berkinerja tinggi…

Mesin Pengering Briket Arang Kotak

Mesin pengering briket arang berbentuk kotak ini adalah sebuah…

Mesin Pemotong Kayu Gaya Drum

Penghancur kayu model drum digunakan di…