機能の概要

連続炭化炉は、もみ殻、ココナッツ殻、木材チップ、おがくずなど、さまざまなバイオマス材料から高品質の炭を大規模に生産するように設計されています。

400〜2000kg/hの容量で、高温条件下で無酸素乾留を行い、わら、パーム核殻、竹くずなどの材料の炭化率を高めます。

これにより、継続的な炭化炉は、持続可能な炭を効率的に生産しようとしている企業にとって理想的なソリューションになります。

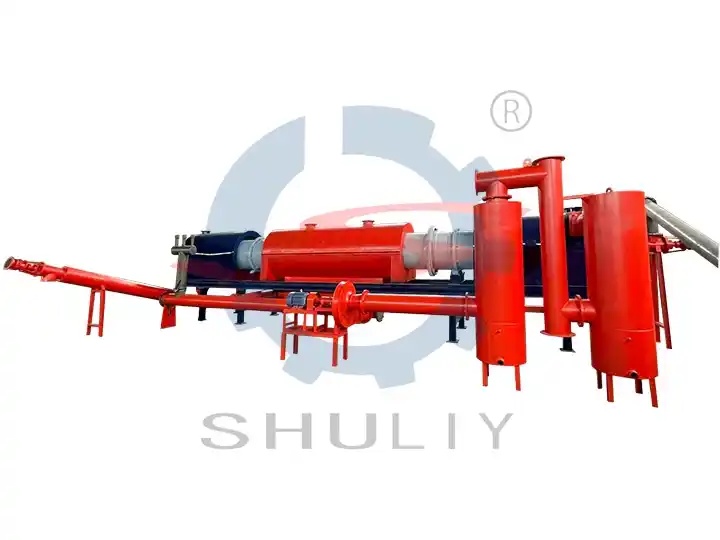

販売用の連続炭化炉

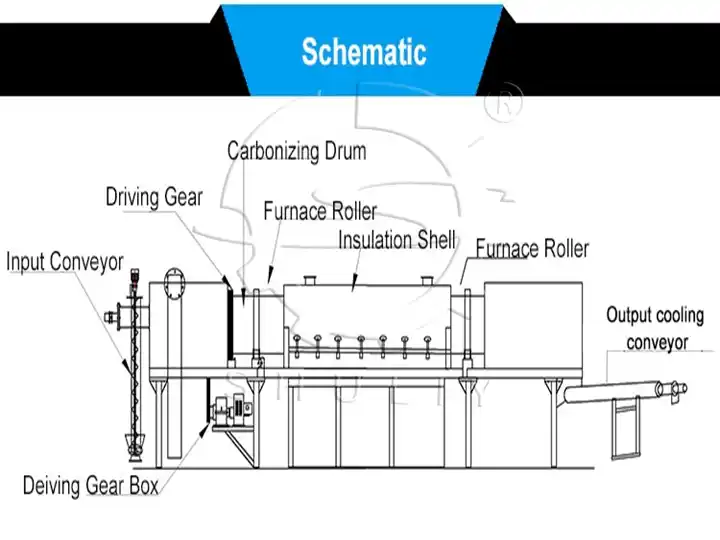

連続炭化炉は、スクリュー供給システム、水平供給、回転ドラム、凝縮排出、バーナー、燃焼室、精製ユニット、制御盤で構成されています。

連続炭化炉の概略図

主要コンポーネントの展示

- 炭素化剤。 バイオマスを木炭に変換するためのコアユニット。

- ガス装置。 炭化プロセス中に可燃性ガスの生産を促進します。

- すすプロセッサ。 不純物を除外し、有害な粒子の放出を防ぎます。

- 可燃性ガス浄化器。 きれいな排出物を確保するために、ガスから汚染物質を除去します。

- 可燃性ガスコンデンサー。 さらに使用するためにガスを集めて凝縮します。

- ドラフトファンを誘発しました。 システム全体のガス循環を促進して、効率的な動作を維持します。

連続炭化炉は、環境への影響を最小限に抑えながら高品質の木炭を生産するために相互に作用するいくつかの重要なコンポーネントで構成されています。

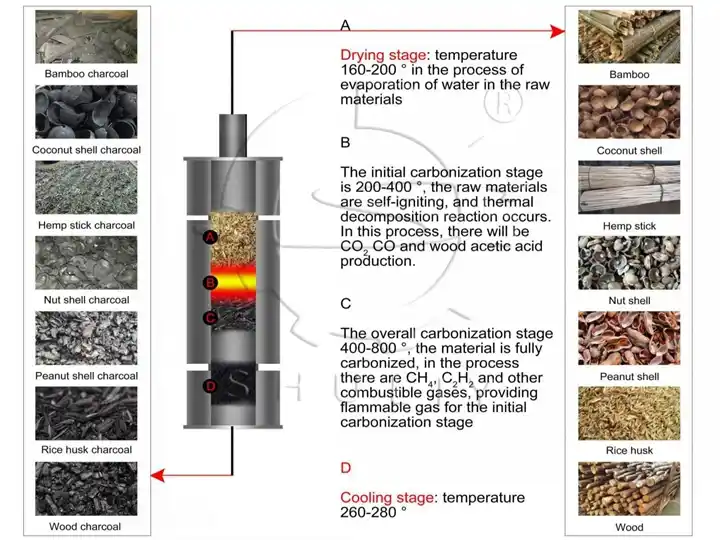

連続炭化炉の生産プロセス

連続炭化炉は、燃焼プロセスから生成された熱を活用してバイオマス原料の熱分解を開始することにより動作します。

材料が回転ドラムを通過すると、慎重に制御された高温にさらされ、複雑な有機化合物を分解し、揮発性ガスを放出します。

次に、これらのガスは燃焼室で燃焼し、炉のエネルギー効率を大幅に改善しながら、有害な排出量を最小限に抑えます。

- 熱利用燃焼熱を利用してバイオマス原料の熱分解を開始します。

- 回転ドラム。 バイオマスはドラムを通過し、高温に均等にさらされることを保証します。

- 効率的な分解。 高温は有機化合物を分解し、揮発性ガスを放出します。

- エネルギーの最大化揮発性ガスは燃焼室で燃焼され、最適なエネルギー利用が行われます。

- 排出削減生産過程で生成される木材タールと木酢は燃焼され、環境汚染がないことを保証します。水はリサイクル可能で、水資源の節約と保護に役立ちます。

連続炭化炉仕様

ホットセールの連続炭化炉:

| モデル | SL-CF800 | SL-CF1000 | SL-CF1200 |

| 直径(mm) | 800 | 1000 | 1200 |

| 能力(kg/h) | 400-600 | 800-1000 | 1200-2000 |

| 主電力(kw) | 18.5 | 18.5 | 20 |

| 炭化温度(℃) | 500-800 | 500-800 | 500-800 |

| ファン出力(kw) | 5.5 | 5.5 | 5.5 |

カスタマイズサービスをサポートしています。私たちのモデルや製品の詳細についてもっと知りたい場合は、お気軽にお問い合わせください!

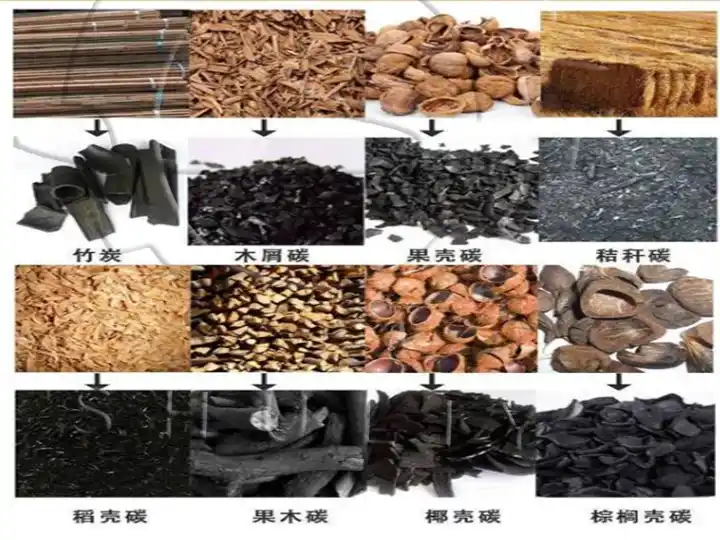

おがくずの木炭製造機に適した材料は何ですか?

おがくずの木炭製造機は、さまざまな原材料を処理することができ、非常に用途が広いためです。

バイオマス、スラッジ、ゴミなどの材料を処理できます。ただし、サイズが15cm未満で、水分含有量が15%未満である必要があります。

これらの材料は直接炭化され、炭の効率的で持続可能な生産を可能にすることができます。

- バイオマス材料(たとえば、おがくず、ピーナッツの殻、トウモロコシの茎、米殻)

- 農業残留物(例:バガス、ソルガムの茎、綿の茎)

- 林業廃棄物(たとえば、竹のチップ、枝、ヤシの殻)

- その他の有機廃棄物(例:蒸留器の穀物、コーンコブ、枯れ葉など)

- さまざまな産業からの副産物(たとえば、コーヒーかす、アプリコットの殻、伝統的な漢方薬の残留物)

- さまざまな植物の茎(例:ヒマワリの種の殻、ヤムグラス、麻の茎)

これらの材料はすべて、連続炭化炉で効率的に処理され、高品質の炭を生産できます。

連続炭化炉の利点

- 高効率。 継続的な動作を可能にし、頻繁な積み込みと荷降ろしを排除することにより、生産性を高めます。

- 一貫した出力。 均一な炭化を保証し、最終的な木炭の一貫した品質をもたらします。

- エネルギー効率。 熱回収システムを利用して、煙道ガスと廃熱をリサイクルし、エネルギー消費を減らします。

- 柔軟性。 温度、滞留時間、ガス流量など、さまざまな原材料と炭化の設定に適応します。

- 自動制御。 正確な監視、安全性を高め、人間の介入を最小限に抑えるための高度な自動化を特徴としています。

- 環境への親しみやすさ。 環境基準を満たし、汚染を削減するために、ダスト除去および排出制御システムを組み込みます。

- コスト削減。 高品質の生産量は市場の競争力と収益性を向上させる一方で、労働力とエネルギーコストを削減します。

連続炭化炉の技術機能

- 高自動化。 高温シーリングの高度な技術を備えた組立ラインの生産。さまざまな環境での炭化を可能にします(真空、陽圧、大気保護、酸素なし)。

- 調整可能な温度範囲。 温度は、特定の製品要件を満たすために、50〜1000°Cから正確に制御できます。

- 通常の圧力操作。 ワークショップでは、最小限のほこりで優れた動作条件を保証します。

- 低い空気容積。 最小限の空気量を必要とすることにより、ダスト収集システムへの圧力を軽減します。

- 制御された発射時間。 発火時間を調整して、均一かつ徹底的な炭化を確保することができます。

- エネルギーリサイクル。 包括的な熱エネルギーリサイクルは、熱エネルギー利用効率を向上させます。

- 複数の温度ゾーン。 内側のシリンダーには、製品特性に基づいて温度制御用の複数のゾーンがあります。

- 溶媒回復。 材料からの溶媒の回収に便利です。

- 高い充填材料速度。 最適な煙道ガスと最適な熱交換のために、最適な速度で25%で15%を超える充填材料を達成します。

おがくずの木炭製造機はどのように機能しますか?

- デフレクターメカニズム。 原材料は、炭化の主な炉に入り、デフレクターによって導かれた炉の回転とともに水平方向に動きます。

- 継続的な炭化。 材料は、飼料入口から炭素出口に徐々に移動し、その動き中に炭化を受けます。

- エアロック。 飼料と炭素の両方のコンセントには、空気が入るのを防ぐための空気ロックが装備されており、酸素不足の環境を維持しています。

- ドラフトファンを誘導しました。 メイン炉には、連続した給餌および炭化プロセス中に酸素装飾雰囲気を維持するために、誘導されたドラフトファンが装備されています。

- 連続動作。 この設計により、継続的な給餌と炭化が可能になり、効率と生産能力が向上します。

- 炭化の結果が改善されました。 酸素不足の環境は、より良い炭化品質を保証し、炭と竹の炭を生産するのに理想的です。

継続的な炭化炉の顧客ケース

驚くべき成功例として、コンゴの顧客が Shuliy 工場に連続炭化炉と木炭粉砕機を注文しました。

800 ~ 1000kg/h という優れた生産能力を備えたこれらの機械は、高品質のバーベキュー用炭の製造と販売を容易にするために特に選ばれました。

お問い合わせ

結論として、連続炭化炉は、持続可能な炭生産の分野における革新の灯台として際立っています。その連続プロセス、効率的なバイオマス変換、環境に優しい運転は、よりグリーンな実践を求める産業にとって不可欠な資産となっています。

さらに、当社では、ホイスト炭化炉と水平炭化炉の2つの他のモデルの炭化炉も提供しています。

各モデルは、木炭生産と持続可能なエネルギー ソリューションにおける多様なニーズに応える独自の機能を備えています。当社のさまざまな炭化炉を調べて、今日の木炭生産へのアプローチに革命を起こしてください。

人気商品

炭ブリケット用メッシュベルト乾燥機

メッシュベルト乾燥機は、別名…と呼ばれています。

シーシャ炭化包装機

当社のシーシャ炭包装機は重要な…

硬木炭化用垂直炭化炉

この垂直炭化炉は…に使用できます

ラウンド&キューブフーカー炭用のシーシャ炭機

当社の人気のシーシャ用木炭機は高品質な…

米殻乾燥機 | 回転乾燥機販売中

私たちの稲わら乾燥機、または回転式…

圧縮木パレット機械 for Presswoodパレット

当社の圧縮木製パレット機は…設計されています…

動物飼料ペレット機 | ペレット飼料ミル

Shuliyは…向けの飼料ペレット機を提供しています

木材剥皮機 | 丸太皮むき機

木材剥皮機(別名ログデバーカーとも呼ばれる)は…

バーベキュー炭用炭ブリケット包装機

当社の木炭ブリケット包装機、つまりBBQ用木炭…