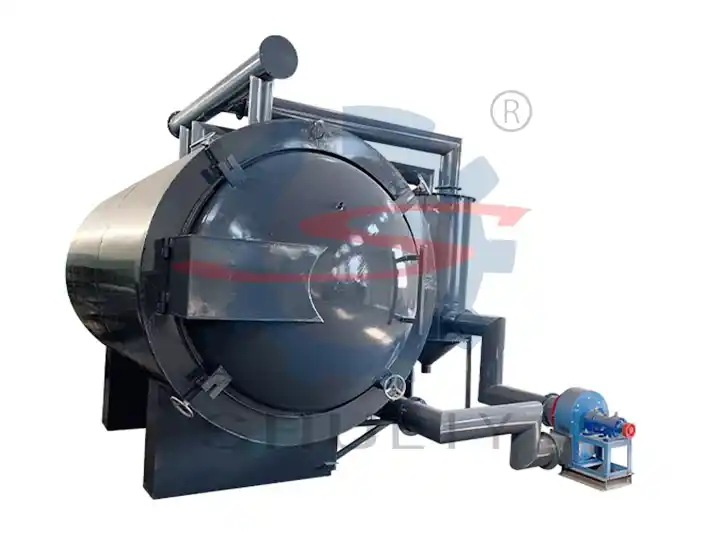

Forno horizontal a carvão para produção de biochar

Máquina horizontal para fazer carvão | Forno a carvão

Forno horizontal a carvão para produção de biochar

Máquina horizontal para fazer carvão | Forno a carvão

Visão geral dos recursos

Um forno de carvão horizontal é um dispositivo de alto desempenho, projetado para uma carbonização industrial eficiente e ecológica. Apresenta uma estrutura horizontal inovadora, integrando tecnologia de controlo de temperatura precisa e um sistema de combustão de poupança de energia. Pode produzir carvão de forma eficiente a partir de madeira, bambu, serradura, cascas de coco e outros materiais.

Com uma capacidade diária de900-3000 kg(12-14 horas por lote), atende às necessidades de produção de pequena a grande escala. Este forno é amplamente utilizado na produção de carvão vegetal, fabricação de carvão ativado, tratamento térmico de metais e processamento de matérias-primas químicas.

O forno de carbonização horizontal apresenta uma estrutura selada e resistente ao calor, composta por uma casca exterior, revestimento interior, tubulações e um sistema de purificação de gases de combustão. Estes componentes trabalham em conjunto para garantir uma carbonização uniforme e estável.

Com uma eficiência superior a 95%, o forno oferece uma alta utilização de energia térmica, um ciclo de produção curto e um excelente rendimento de carvão. O seu desempenho estável, operação fácil, baixo consumo de energia e alta produção fazem dele uma escolha muito popular entre as empresas de produção de carvão.

Aplicação de forno de carvão horizontal

A fornalha horizontal de carvão, também conhecida como fornalha de carvão em toras ou máquina horizontal de produção de carvão, é uma solução de carbonização altamente versátil e eficiente.

Projetado para produção de escala industrial, converte vários materiais de biomassa-como lascas de madeira, serragem e resíduos agrícolas-em carvão ou biochar de alta qualidade através de um processo de carbonização controlada.

- Agricultura e silvicultura - Utilizado para o processamento de resíduos agrícolas e florestais em biochar para melhoria do solo e seqüestro de carbono.

- Proteção Ambiental -Ajuda a reduzir o desperdício, convertendo a biomassa em carvão ecológico, apoiando soluções de energia sustentável.

- Produção comercial de carvão -Ideal para empresas que exigem carbonização em larga escala e alta eficiência para produzir carvão para combustível, carbono ativado ou aplicações industriais.

Aqui estão algumas fotos mostrando os resultados da carbonização dos produtos.

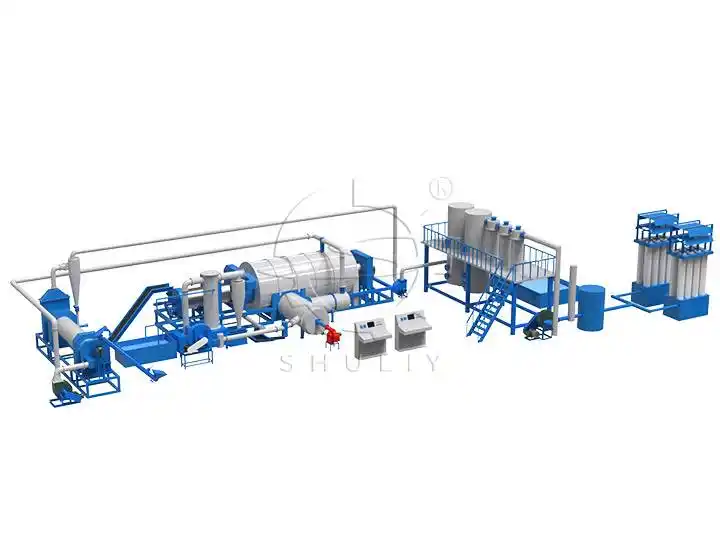

Para atender a diversas necessidades de carbonização, também oferecemos fornalhas de carbonização contínua, fornalhas de carbonização com fluxo de ar vertical e outros modelos especializados.

Como funciona a máquina de fazer o carvão horizontal?

- Carregamento de biomassa. Os materiais de biomassa são carregados no forno de carvão horizontal.

- Ignição e geração de calor. O forno é inflamado, gerando calor dentro da câmara e iniciando o processo de carbonização.

- Controle de temperatura. A temperatura é geralmente controlada em cerca de 600 ℃.

- Até aquecimento. O layout horizontal garante mesmo aquecimento dos materiais de biomassa.

- Liberação de gases e voláteis. Gases evoluídos e componentes voláteis são liberados durante esta fase.

- Fluxo de ar controlado. O fluxo de ar controlado é mantido dentro do forno horizontal.

- Remoção eficiente. Isso garante a remoção eficiente da umidade, substâncias voláteis e outras impurezas dos materiais de biomassa.

- Transformação gradual. Os materiais passam por uma transformação gradual, transformando-se em carvão de alta qualidade.

Vantagens do design horizontal

- Fluxo de ar ideal. Ele também fornece fluxo de ar ideal, que é crucial para a remoção eficiente de impurezas e a produção de carvão de alta qualidade.

- Distribuição uniforme de calor. O projeto horizontal garante a distribuição uniforme de calor em todo o processo de carbonização.

Processo de carbonização no forno de carvão de madeira

O processo de carbonização num forno de carvão em tronco segue uma sequência estruturada para garantir uma produção de carvão eficiente e controlada. Ao utilizar um sistema bem projetado, o forno converte efetivamente matérias-primas em carvão de alta qualidade através de um processo de combustão cíclica.

- Carregando as matérias -primas

- Seções de tronco e galhos são cuidadosamente arranjadas dentro de uma estrutura de ferro, que é então suavemente empurrada para dentro da cavidade do forno usando uma pista de transporte.

- Alternativamente, cascas de coco, galhos partidos e outros materiais biomassa podem ser carregados diretamente no tambor do forno horizontal de carvão.

- Selando o forno

- A tampa do forno horizontal de carvão com fluxo de ar é fechada com segurança.

- Quaisquer lacunas próximas à tampa são vedadas com lama ou algodão isolante para evitar fugas de ar e garantir um ambiente hermético.

Ignição e aquecimento inicial

- Um forno de gaseificação é usado para ignitar o combustível na porta de ignição na parte inferior do forno.

- À medida que o combustível queima, a temperatura dentro do forno aumenta gradualmente.

Monitorização da temperatura e circulação de gás

- O termômetro do forno é monitorado de perto. Quando a temperatura chega 400 ° C., o forno de gaseificação está desligado.

- Nesta fase, o gás combustível produzido dentro do forno de carbonização sofre Combustão cíclica, reduzindo a necessidade de combustível externo.

Carbonização final e formação de carvão

- O processo de aquecimento cuidadosamente regulado garante uma transformação eficaz das matérias-primas em carvão de alta qualidade.

- O fluxo de ar controlado e a distribuição de calor contribuem para um processo de carbonização consistente e eficiente.

Seguindo estes passos sistemáticos, o forno de carvão em tronco maximiza a eficiência do combustível, minimiza resíduos e garante uma produção de carvão de alto rendimento, tornando-se uma solução ideal para necessidades comerciais de carbonização.

Estrutura do forno de carvão horizontal

Isolamento térmico aprimorado

- As superfícies de rocha de isolamento térmico altamente eficientes são integradas na tampa e no corpo do forno, garantindo retenção superior de calor.

- O projeto avançado de vedação aumenta o isolamento térmico, impedindo a perda de calor durante o processo de carbonização.

- A construção otimizada do forno mantém temperaturas internas estáveis, melhorando a eficiência energética geral.

Circulação eficiente de gases de combustão

- Uma rede de tubos é integrada ao forno, conectando as seções superior e inferior para otimizar o fluxo de gás.

- Os tubos circulantes facilitam o movimento de gás combustível dentro do cilindro, aumentando a eficiência energética.

- Tubos adicionais são projetados para filtrar gás de combustão, melhorando o desempenho ambiental do forno.

Sistema de carrinho conveniente

- Os sistemas de carrinho são incluídos para facilitar o transporte de matérias -primas e carvão acabado.

- Projetado para lidar com a capacidade substancial e a alta produção do forno, garantindo uma operação suave.

- Aumenta a eficiência e a conveniência gerais, reduzindo a intensidade do trabalho para os operadores.

Parâmetro do forno de carvão horizontal

| Modelo | Capacidade | Peso da máquina | Dimensões (L × W × H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg/12–14 horas | 2500 kg | 3 × 1,7 × 2,2 metros |

| SL-1500 | 1500–2000 kg/12–14 horas | 4000 kg | 4,5 × 1,9 × 2,3 metros |

| SL-1900 | 2500–3000 kg/12–14 horas | 5500 kg | 5 × 2,3 × 2,5 metros |

Recursos horizontais de fabricação de carvão

- Corpo do forno de três camadas. O corpo do forno é construído com três camadas, e a porta é revestida com algodão retardador de chama e isolamento de calor, garantindo excelente tensão, retenção de calor e eficiência energética enquanto reduz o consumo de combustível.

- Sistema de recuperação de gás de combustão. A tecnologia integrada de recuperação de gás de combustão aumenta a eficiência de combustível, minimizando o desperdício de recursos.

- Projeto de carro do forno. O carro do forno móvel simplifica a operação, reduzindo a intensidade do trabalho e tornando o carregamento e a descarga mais conveniente.

- Alta capacidade e carbonização única. A máquina acomoda grandes cargas de material, permitindo carbonização eficiente em lote.

- Várias opções de aquecimento. Compatível com várias fontes de combustível, incluindo madeira, carvão e gás natural, fornecendo flexibilidade com base na disponibilidade e custo.

- Emissões sem fumo. Um sistema de purificação de gases de combustão de alto desempenho garante uma operação ecológica com emissões mínimas de fumaça.

- Sistema de resfriamento de água. Um sistema de refrigeração rápido acelera o processo, melhorando a eficiência e a produtividade gerais.

Contate-nos

Se você estiver interessado em nosso produto e quiser saber mais detalhes ou solicitar um orçamento, não hesite em nos contatar.

Nossa equipe profissional dedica-se a fornecer suporte e assistência para ajudá-lo a atingir seus objetivos de produção de carvão. Aja agora e junte-se a nós na moldagem do futuro da produção sustentável de carvão!

Produto quente

Forno de carbonização vertical para produção de carvão de madeira dura

Esta fornalha de carbonização vertical pode ser utilizada para…

Máquina de Briquetes de Carvão | Extrusora de Carvão

A máquina de briquetes de carvão, também conhecida como…

Máquina de Triturador de Madeira | Máquina Industrial de Serragem

As máquinas triturador de madeira são concebidas para processar eficientemente…

Máquina de Descascar Madeira | Máquina de Pelar Troncos

Máquina de Descascar Madeira, também conhecida como Máquina de Toras…

Máquina de Paletes de Madeira Comprimida para Palete de Presswood

A nossa máquina de paletes de madeira comprimida foi concebida para…

Misturadora de Carvão | Misturador de Pó de Carvão

Esta máquina misturadora de carvão também pode ser chamada…

Girador de Madeira de Disco | Máquina de Fazer Lascas de Madeira

A debulhadora de madeira de disco apresenta-se como uma solução versátil…

Máquina de Fiação de Blocos de Palete de Madeira

A máquina de fabrico de blocos para paletes de madeira utiliza serrim e…

Triturador Completo de Madeira | Serradora de Paletes de Madeira

O britador abrangente, comumente referido como um…