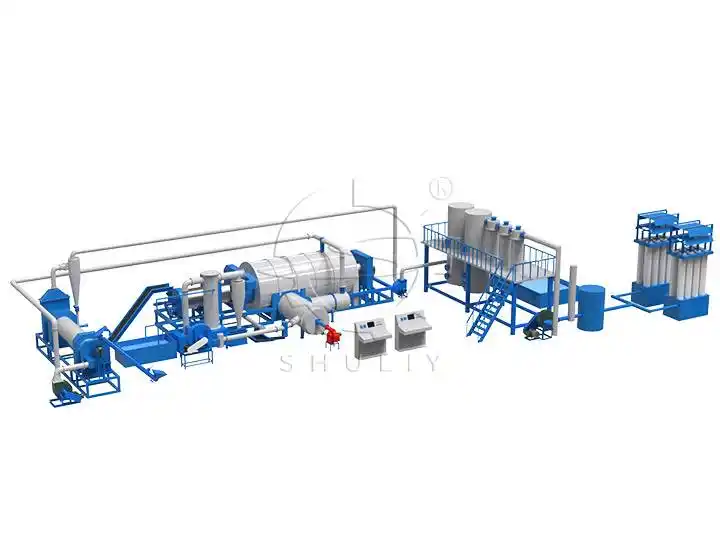

A Complete Charcoal Production Line has been Installed in Zimbabwe

In May 2025, our company exported a complete charcoal production line to Zimbabwe. It has now been successfully installed and put into production.

Project Background

In March 2025, a client from Zimbabwe contacted our company. The client, mainly engaged in charcoal sales and export, planned to build a modern charcoal production line to increase output and improve product quality, meeting the growing demand in local and surrounding markets.

After several rounds of communication and solution comparison, the client finally chose our company’s complete charcoal production solution, which includes the full process of crushing, mixing, briquetting, and continuous carbonization.

Customer Requirements

- Raw material: Log wood

- Final product: High-density charcoal briquettes

- Production capacity: About 500 kg per hour

- Special requirements: Easy operation, energy-saving, eco-friendly, and suitable for continuous operation

Charcoal Production Line Configuration

Based on the customer’s raw materials and production requirements, we provided the following equipment setup:

1. Wood Crusher

Used to crush logs, branches, and waste wood into fine particles of 3–5 mm, preparing them for the briquetting process.

The machine adopts a heavy-hammer design with a solid structure and uniform discharge.

2. Mixer

Mixes the crushed sawdust with a binder thoroughly to ensure even material composition and proper moisture content.

The inner wall of the mixing tank is made of stainless steel, resistant to corrosion and easy to clean.

Compresses the mixed material into dense stick-shaped briquettes suitable for carbonization.

It provides high forming pressure, resulting in smooth, high-density briquettes.

4. Continuous Carbonization Furnace

A fully sealed continuous carbonization system capable of 24-hour non-stop operation.

The carbonization efficiency reaches up to 95%, equipped with a flue gas purification and recycling system that reuses combustible gases for energy saving and environmental protection.

The temperature is automatically controlled to ensure uniform carbonization and high carbon content in the final product.

Installation and Operation

After the equipment was shipped to Zimbabwe, our technical engineers provided remote guidance for installation and commissioning. The client’s team completed the assembly of the production line within one week.

After multiple trial runs, the entire production line operates stably, producing fully carbonized briquettes of excellent quality.

The daily output reaches 6–8 tons of finished charcoal, with energy consumption reduced by over 30% compared to traditional carbonization methods.

Summary & Project Highlights

- Continuous and Efficient Production: The continuous carbonization furnace can operate 24 hours non-stop, greatly improving production efficiency.

- Energy-Saving and Eco-Friendly Design: The flue gas recycling and purification system reduces energy waste and smoke emissions.

- Stable Product Quality: Automatic temperature control ensures high charcoal yield, uniform quality, and high carbon content.

- Easy and Safe Operation: The compact, highly automated line reduces manual labor and maintenance costs.

- Strong Market Competitiveness: The produced high-density briquettes burn longer and are well-received in the local market.

Charcoal Production Line vs. Manual Charcoal Production

| Comparison Item | Charcoal Production Line | Traditional Manual Charcoal |

|---|---|---|

| Production Capacity | 6–8 tons of finished charcoal per day | About 1–1.5 tons per day |

| Carbonization Efficiency (Yield) | 90–95% | 60–70% |

| Carbonization Cycle | 6–8 hours per batch continuous operation possible | 2–3 days per batch, intermittent production |

| Energy Consumption | About 60–80 kWh per ton of charcoal | 100–150 kg of wood or coal per ton of charcoal |

| Labor Requirement | 2–3 operators for the whole line | 8–10 workers high labor intensity |

| Charcoal Quality Stability | Uniform quality carbon content 85–90% | Uneven quality carbon content 70–75% |

| Smoke Emission | Equipped with a flue gas purification and recycling system almost no black smoke | High smoke and dust serious pollution |

| Unit Production Cost | About $50–60 per ton | About $100–120 per ton |

| Annual Output (based on 300 days) | 1,800–2,400 tons | 300–450 tons |

| ROI (Return on Investment) | 6–10 months | Equipped with a flue gas purification and recycling system, almost no black smoke |

Summary

The comparison shows that the automated charcoal production line outperforms manual charcoal production in terms of capacity, energy consumption, labor cost, and environmental performance:

- Output: 3–5 times higher

- Energy consumption: Reduced by over 40%

- Labor savings: Over 70%

- Cost per ton: Nearly 50% lower

The charcoal production line not only improves economic efficiency but also aligns with current trends in energy saving, emission reduction, and green production, making it an ideal replacement for traditional brick-kiln charcoal methods.