Shisha Hookah Charcoal Production Line

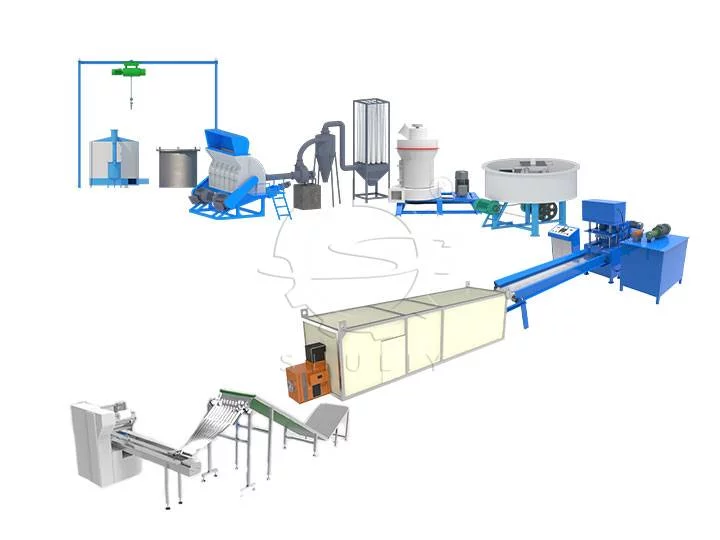

Our shisha hookah charcoal production line equipment contains continuous carbonization furnace, hammer mill, charcoal grinder mixer, hookah charcoal machine, drying room or mesh belt dryer, etc. And you will yield many advantages and returns. If you want to invest in this line, Shuliy will offer you reliable service after sales and quick response after your inquiry.

What Are the Raw Material for Shisha or Hookah?

The raw materials for shisha or hookah charcoal production mainly include coconut shells, bamboo, fruitwood, and other natural materials. These materials are chosen for their low ash content, high calorific value, and ability to produce clean and flavorful smoke.

Shisha Charcoal Production Line Process

The shisha charcoal production line involves several essential steps. First, the raw materials are pulverized into fine powder by a crusher. Next, the charcoal powder is mixed with a binder and water to form a dough-like mixture.

The mixture is then compacted into shape using a shisha charcoal briquette machine. After molding, the briquettes are dried in a dryer to reduce moisture content. Finally, the dried shisha charcoal briquettes undergo carbonization in a carbonization furnace to improve burning efficiency and enhance the flavor.

Shisha Hookah Charcoal Production Line Machine

The shisha hookah charcoal production line machine includes a crusher, mixer, briquette machine, dryer, and carbonization furnace. These machines work together seamlessly to ensure a smooth and efficient production process.

Continuous Carbonization Furnace

This machine in the shisha hookah charcoal production line is designed to handle a wide range of raw materials, such as sawdust, rice husk, and wood chips. This furnace is particularly suitable for small, lightweight materials, making it ideal for directly charring wood pellets.

Hammer mill

In the shisha hookah charcoal production line, it is used to crush and grind the raw materials into fine particles, ensuring the proper size and consistency required for making high-quality hookah charcoal.

Charcoal grinder mixer

It is used to mix and grind the charcoal powder with other ingredients to create a homogeneous and consistent mixture. This ensures that the final shisha charcoal products have the desired flavor and texture, making it an indispensable part of the charcoal production process.

Hookah charcoal machine

It is specifically designed to compress charcoal powder and other materials into high-quality hookah charcoal briquettes with various shapes and sizes. This machine plays a crucial role in automating the shisha hookah charcoal production line process and ensuring the consistency and efficiency of the final products.

Dryer

In the shisha hookah charcoal production line, the dryer is a crucial component for efficiently reducing the moisture content of the raw materials. There are different types of dryers used in this process, including the drying room and the mesh belt dryer.

Hookah briquette packaging machine

It is designed to efficiently pack the produced hookah charcoal briquettes into bags or other containers, ensuring convenient and hygienic storage and transportation.

How to Make Desired Shisha?

To make desired shisha, manufacturers must carefully select high-quality raw materials and control the production process.

Next, properly adjusting the ratio of binder to charcoal powder ensures the briquettes hold their shape and provide a smooth smoking experience. In the end, precise temperature control during carbonization is crucial to achieve the desired burning properties and flavors.

Hookah Charcoal Production Line Return After the Investment

Investing in a hookah charcoal production line can yield promising returns. The increasing popularity of hookah culture worldwide ensures a consistent demand for high-quality shisha charcoal. With proper marketing and product positioning, manufacturers can capitalize on this growing market and establish a stable customer base, leading to a profitable venture.

Service of After Sales in Shisha Charcoal Production Line

After sales service in the shisha charcoal production line includes:

- Technical Support: Providing technical guidance and solutions for any issues during the production process.

- Machine Installation: Assisting in the installation and commissioning of the production line.

- Training: Conducting training sessions for operators to ensure safe and efficient operation.

- Quality Assurance: Ensuring the quality of shisha charcoal produced meets the required standards.

- Maintenance Services: Providing regular maintenance to keep the equipment in optimal condition.

- Customer Support: Offering 24/7 customer support for any inquiries or assistance needed.

By investing in a shisha hookah charcoal production line, businesses can not only meet the increasing demand for shisha charcoal but also benefit from the reliable after-sales service and support provided by the Shuliy supplier, ensuring a successful and sustainable production solution. For price, send an inquiry now.

Hot Product

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Charcoal Briquettes Packing Machine for Barbecue Charcoal

Our charcoal briquettes packing machine, namely BBQ charcoal…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Coal Briquette Machine | Honeycomb Coal Press Machine

Coal briquette machine can produce different shape and…

Vertical Carbonization Furnace for Hardwood Charcoal Making

This vertical carbonization furnace can be used for…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…