Honeycomb Coal Production Line

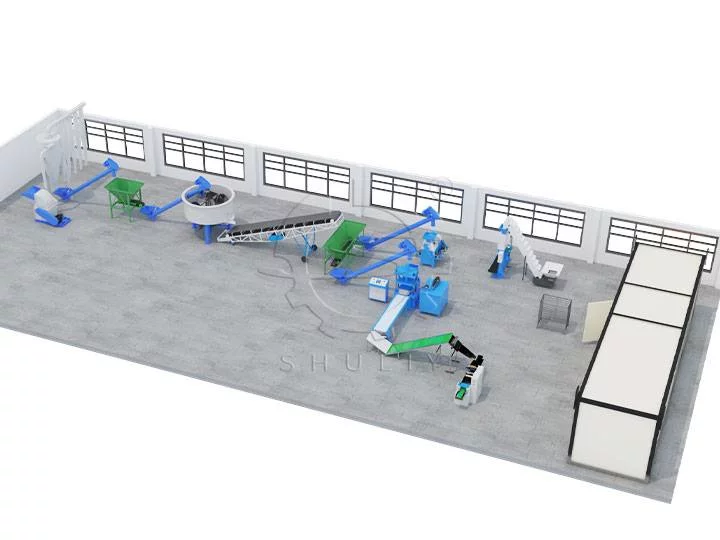

In honeycomb coal production line, you can produce different types of honeycomb-shaped coal briquettes. In honeycomb briquettes processing plant, it needs to use several series of equipment, including coal crusher, honeycomb coal press machine, carbonization furnace, etc. And investing it has many advantages. Welcome to contact us to get its price.

Raw Material in Honeycomb Coal Production Line

In a honeycomb coal production line, the primary raw material used to produce honeycomb coal briquettes is coal dust or charcoal fines. Coal dust refers to finely ground coal particles that result from the crushing or pulverizing of coal.

Charcoal fines, on the other hand, are the residual particles left after the carbonization or pyrolysis process of wood, coconut shells, or other biomass materials.

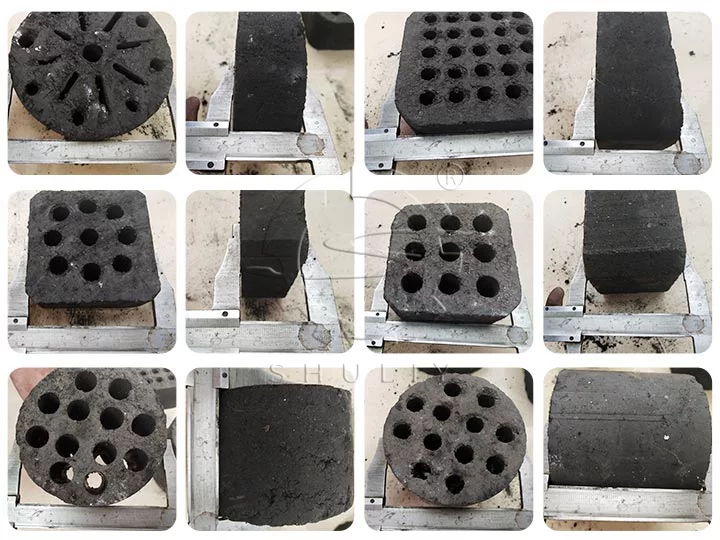

Final Products You Can Produce

From a honeycomb coal production line, the final products are honeycomb-shaped coal briquettes. These briquettes are compact and have a unique hexagonal shape, resembling a honeycomb structure, hence the name.

Honeycomb coal briquettes are an efficient and clean-burning fuel source, commonly used for heating, cooking, and industrial applications. They have several advantages, such as high heat output, long burning time, low ash content, and reduced smoke and emissions compared to traditional raw coal.

Honeycomb Coal Production Line Machine

Our honeycomb coal production line involves several machines, including the coal crusher, mixer, honeycomb coal briquette machine, and the final product cutter.

honeycomb coal briquette production line machine list

Coal Crusher

In honeycomb coal production line, it crush the raw coal into small particles for easier handling and processing.

Coal Mixer

The coal mixer is used to mix the crushed coal with binder and other additives to improve the briquette’s binding and burning properties.

Honeycomb Coal Briquette Machine

This is the core machine in the production line, responsible for shaping the coal mixture into honeycomb-shaped briquettes.

Briquette Drying Machine

After forming, the briquettes need to be dried to reduce their moisture content, improving their burning efficiency and stability.

honeycomb charcoal briquette production line machine list

Carbonization Furnace

This machine is used for the carbonization process, converting the dried briquettes into solid and stable charcoal with higher heat value.

Charcoal Crusher

The charcoal crusher in honeycomb coal production line is used to crush the charcoal into fine powder, preparing it for further processing or packaging.

Charcoal Mixer

It will mix charcoal powder with binders and additives before forming into charcoal briquettes.

Charcoal Briquette Machine

Similar to the honeycomb coal briquette machine, this machine is designed specifically for shaping charcoal briquettes in various shapes.

Charcoal Briquette Drying Machine

The dried charcoal briquettes need further drying to remove excess moisture and improve their quality.

Advantages of Investing in Honeycomb Briquettes Processing Plant

Investing in a Honeycomb Briquettes Processing Plant or honeycomb coal production line offers several advantages:

High Profitability: Honeycomb briquettes are in high demand due to their clean-burning properties and long-lasting heat. This leads to a steady market demand and good profit potential for investors.

Eco-Friendly Fuel: Honeycomb briquettes are made from renewable biomass resources, such as sawdust, crop waste, or wood chips, making them an eco-friendly alternative to traditional fossil fuels.

Cost-Effective Production: The production process of honeycomb briquettes is relatively simple and efficient, which helps in reducing production costs and increasing profitability.

Versatile Applications: Honeycomb briquettes can be used for various heating purposes, such as cooking, heating, and industrial applications, providing a diverse range of potential customers.

Sustainable Business Model: The growing awareness of environmental issues and the need for sustainable energy sources ensures a continuous demand for eco-friendly briquettes.

Parameters of Coal Briquette Press Machine

| mold | XFM125 | XFM83 | FM220 | FMJ102 | FMJ-120 |

| Forming height (mm) | 70-100 | 70-90 | 75-90 | 70-80 | 70-80 |

| Stamping times (times/min) | 48 | 48 | 35 | 45 | 48 |

| Motor power (kW) | 7.5 | 7.5 | 11 | 4.5 | 7.5 |

| Machine weight (kg) | 1600 | 1800 | 3800 | 1100 | 1400 |

| Formed coal specification (mm) | φ100×75 φ125×75 | φ150×90 φ140×90 | φ220×90 φ200×90 | φ100×75 φ120×75 | φ120×75 φ100×75 |

Shuliy Service for You

With Shuliy’s dedicated service and reliable equipment, you can count on a seamless experience in setting up and operating your wood chipper, charcoal briquette machine, or any other machinery in your honeycomb coal production line. Your success is our priority, and we are here to support your journey every step of the way.

Professional Guidance: Our experienced team is ready to guide you in choosing the most suitable equipment for your specific needs. Whether you are looking for a wood chipper, charcoal briquette machine, or any other machinery, we offer expert advice to ensure you make the right investment.

Customization: We offer customization options for our machines, allowing you to get the equipment to your unique preferences and production demands.

Quality Assurance: Shuliy takes pride in the quality of our machines. We adhere to strict quality control measures during the manufacturing process to deliver reliable, durable, and high-performing equipment.

Timely Delivery: Our efficient logistics team ensures that your orders are delivered promptly and safely.

After-Sales Support: Our commitment to customer satisfaction extends beyond the sale. We offer comprehensive after-sales support, including installation guidance, troubleshooting assistance, and spare parts availability.

Global Reach: Shuliy serves customers worldwide, and we are proud of our reputation as a trusted supplier in the industry.

Hot Product

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a…

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…

Rice Husk Drying Machine | Rotary Dryer for Sale

Our rice husk drying machine, or a rotary…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…