Wood debarker effective usage in Mali

As a leading supplier of wood processing equipment, our company recently supplied a wood debarker to a prominent furniture manufacturer based in Mali.

This case study highlights our successful collaboration and the impact of our wood debarker on enhancing their production capabilities.

Client Background:

Our client is a well-established furniture manufacturer in Mali, renowned for crafting high-quality wooden furniture using locally sourced timber.

With a commitment to sustainability and quality craftsmanship, they sought innovative solutions to streamline their wood processing operations.

Challenges Faced:

Prior to acquiring our wood debarker, our client grappled with inefficiencies stemming from outdated wood processing machinery.

The low efficiency of their existing equipment posed significant challenges to their production workflow, resulting in prolonged processing times and hindering their overall productivity.

Solution Provided:

Understanding the client’s requirements, we recommended our advanced wood debarker tailored to their specific needs.

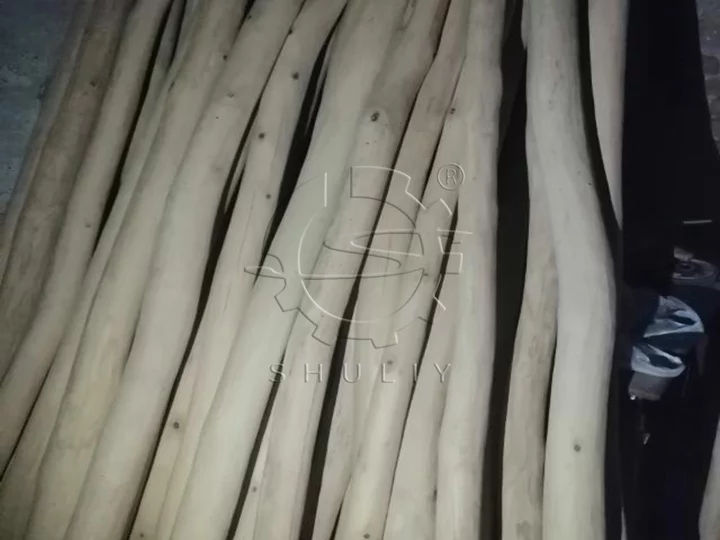

Our debarker offered automated bark removal, significantly reducing processing time and labor costs while ensuring consistent quality of debarked timber.

Implementation:

Upon receiving the wood debarker, our technical team provided on-site installation and training to the client’s staff, ensuring seamless integration into their production line.

We collaborated closely with their team to optimize machine settings for different wood species and sizes, maximizing efficiency.

Results Achieved:

The implementation of our wood debarker yielded remarkable results for our client:

- Increased Efficiency: The automated debarking process led to a substantial reduction in processing time, allowing our client to accelerate their production throughput.

- Cost Savings: By minimizing labor requirements and optimizing resource utilization, our client achieved significant cost savings in their wood processing operations.

- Improved Product Quality: The consistent and precise bark removal ensured the production of high-quality timber, enhancing the overall aesthetics and durability of their furniture pieces.

- Enhanced Sustainability: With improved efficiency and reduced waste, our client advanced their sustainability goals, aligning with their commitment to responsible forestry practices.

Conclusion:

Our collaboration with the furniture manufacturer in Mali exemplifies the transformative impact of our wood debarker on enhancing wood processing efficiency, reducing costs, and improving product quality.

By delivering innovative solutions tailored to our client’s needs, we remain committed to empowering businesses worldwide in their pursuit of excellence in wood processing.