What is a horizontal charcoal making furnace and how does it work?

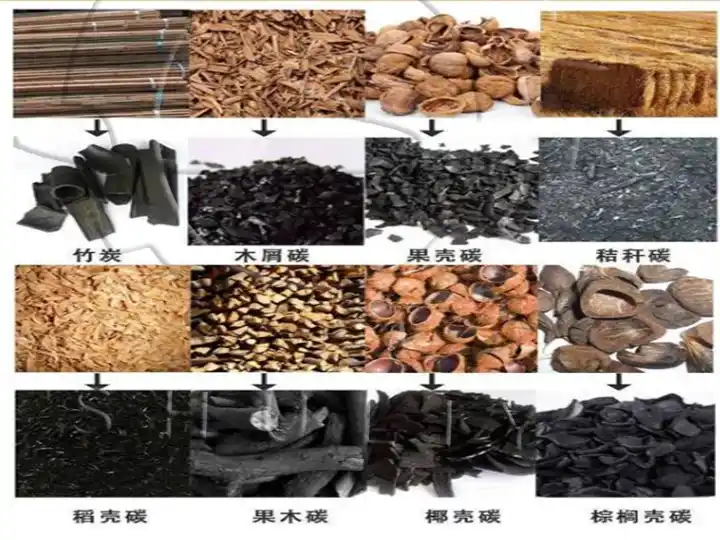

Horizontal charcoal making furnace is a device that converts wood, bamboo, or agricultural and forestry waste into charcoal. Among many carbonization machines, it is widely used in industrial and household charcoal production because of its reasonable structure, easy operation, and stable carbonization effect.

What is a horizontal charcoal making furnace?

A horizontal charcoal making furnace is a carbonization device placed horizontally. The furnace has a horizontal structure: raw materials are loaded into the chamber from the front, and the finished charcoal is discharged from the other end. Compared with a vertical charcoal furnace, its advantages are:

- Flat furnace chamber with a large material spreading area

- Even heat distribution, ensuring good carbonization

- Easy loading and unloading, saving labor

- Compact structure and safe operation

Working Principle of a Horizontal Charcoal Furnace

The core working principle of a horizontal charcoal furnace is pyrolysis carbonization.

Loading

Spread the raw materials evenly in the furnace chamber. Keep the layer thickness moderate to avoid dense spots that affect heat transfer.

External Heating and Ignition

The furnace has an external combustion chamber, which can use firewood, gas, or recovered carbonization gas as the heat source. After ignition, the furnace temperature gradually rises, and the raw materials begin to decompose.

Carbonization Process

Under low-oxygen conditions, high temperatures drive out moisture, resins, and volatile substances from the wood.

Gases like carbon monoxide and methane produced in the early stage are reburned, providing internal heat and saving energy while being environmentally friendly.

Cooling and Discharging

After carbonization, control the furnace temperature to let the charcoal cool slowly, preventing spontaneous combustion.

Finally, remove the charcoal from the discharge port to obtain high-quality charcoal.

Temperature Control – Example of Coconut Shell Charcoal

Coconut shell is a hard, high-density biomass material, and its carbonization requires precise temperature control. A horizontal charcoal making furnace can ensure high-quality and high-yield coconut shell charcoal through proper temperature management.

Carbonization Temperature Stages

1. Dehydration Stage (100℃–200℃)

- Purpose: Remove moisture from coconut shells to prevent smoke or cracks during carbonization.

- Control Method: Raise the temperature slowly to avoid surface scorching or uneven carbonization.

2. Pyrolysis Stage (250℃–450℃)

- Purpose: Volatile substances in the coconut shell decompose, producing combustible gases and forming the charcoal framework.

- Control Method: Maintain steady heating and a low-oxygen environment to prevent burning instead of carbonization.

3. Carbonization Stage (450℃–600℃)

- Purpose: Complete carbonization, producing charcoal with high hardness, low ash content, and stable combustion.

- Control Method: Keep high temperature for a set time, then cool gradually to make the charcoal dense and prevent spontaneous combustion.

Carbonization Results of Coconut Shell Charcoal

With precise temperature control, coconut shell charcoal has the following characteristics:

- High Density: Burns longer, suitable for industrial use, and barbecues

- Low Ash Content: Burns cleanly, reducing pollution

- Stable Combustion: Even heat, minimal smoke

- Dense Charcoal: Hard to the touch, not easy to break

Temperature Control Methods of a Horizontal Charcoal Furnace

- External Combustion Chamber Adjustment: Use firewood, gas, or carbonization gas as fuel. Control furnace temperature by adjusting fuel amount and air vents.

- Furnace Chamber Ventilation: Adjust vents or air inlets to control the amount of air entering, ensuring a low-oxygen environment and stable temperature.

- Temperature Monitoring System: Advanced horizontal charcoal making furnaces can be equipped with temperature sensors and a PLC control system for automatic temperature regulation, improving carbonization uniformity and efficiency.

Applications

- Industrial Charcoal Production: Used for smelting, barbecues, and chemical raw material charcoal production.

- Household Carbonization: Small horizontal charcoal furnaces are suitable for farmers or home use.

- Agricultural Waste Treatment: Convert crop straw and nutshells into high-value charcoal, reducing environmental pollution.

Horizontal Charcoal Making Furnace Model Recommendation

| Model | Capacity | Machine Weight | Dimensions (L×W×H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg/12–14 hours | 2500 kg | 3×1.7×2.2 meters |

| SL-1500 | 1500–2000 kg/12–14 hours | 4000 kg | 4.5×1.9×2.3 meters |

| SL-1900 | 2500–3000 kg/12–14 hours | 5500 kg | 5×2.3×2.5 meters |

In which productions can a horizontal charcoal making furnace be used?

The following posts will help you better understand the role of a horizontal charcoal making furnace in the production process.