Compressed Wood Pallet Machine for Presswood Pallet

Wood Pallet Machine | Pallet Press Machine

Compressed Wood Pallet Machine for Presswood Pallet

Wood Pallet Machine | Pallet Press Machine

Features at a Glance

Our compressed wood pallet machine is designed to manufacture presswood pallets, offering versatility with a range of raw materials such as logs, sawdust, waste wood, and more. The pallets produced by our wood pallet making machine boast numerous advantages.

Additionally, our wood pallet press machine ensures efficient production and customizable specifications to meet your specific needs. Leveraging years of industry expertise, we guarantee competitive pricing. Feel free to reach out to us for further inquiries. We look forward to hearing from you soon!

Compressed Wood Pallet Machine Introduction

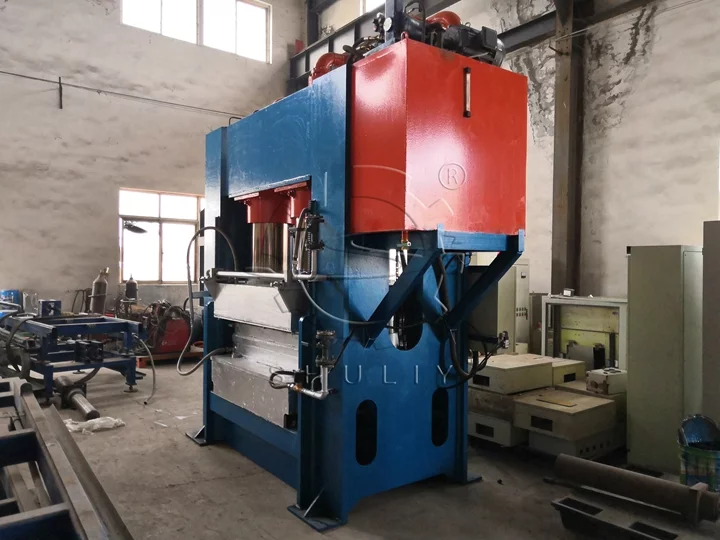

The compressed wood pallet machine, also known as a wood pallet making machine or wood pallet press machine, is an efficient equipment designed to manufacture sturdy and durable pallets from compressed wood fibers.

This innovative machine utilizes high pressure and heat to bind the wood fibers together, creating pallets with consistent dimensions and excellent load-bearing capacity.

The machine’s efficient production process and the resulting high-quality pallets make it an essential asset for businesses involved in logistics, manufacturing, and transportation.

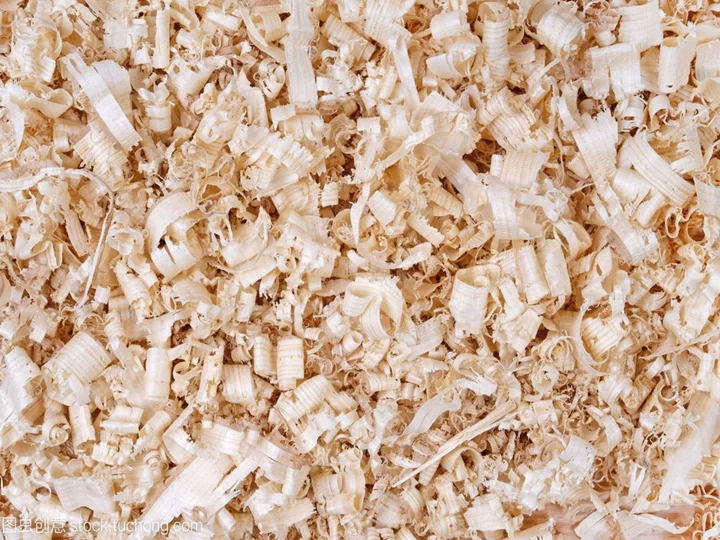

What Material Can Be Used to Make Presswood Pallets?

Presswood pallets from our press pallet machine can be made from a variety of materials including sawdust, logs, wood chips, shavings, waste wood, wood scrap, bamboo, straw, waste kraft paper, and other materials containing wood fiber.

Our compressed wood pallet machine efficiently processes these raw materials to create durable and eco-friendly press pallets, suitable for various industrial and shipping applications.

What Are the Advantages of Presswood Pallets?

Presswood pallets or compressed wood pallets offer several advantages over traditional wooden pallets. Firstly, they are environmentally friendly as they are made from recycled wood fibers, reducing the demand for virgin timber.

Secondly, they have a consistent and uniform structure, ensuring reliable load-bearing capacity and stability. Additionally, presswood pallets are resistant to pests, moisture, and chemicals, enhancing their durability and lifespan.

These pallets from industrial wood pallet machines typically come in various sizes, including dimensions like 400mm to 600mm, 600mm to 800mm, 800mm to 1000mm, 1000mm to 1200mm, and 1100mm by 1100mm.

These pallets exhibit dynamic load capacities spanning from 250kg to 1500kg, with a weight range of 10kg to 20kg.

These versatile pallets find application in various industries including logistics, manufacturing, warehousing, and transportation.

The pallets from our compressed wood pallet machine are ideal for safely and efficiently transporting goods, whether it’s in storage, during transit, or for international shipping. Their lightweight design also contributes to reduced transportation costs and improved handling efficiency.

Features of Compressed Wood Pallet Machine

The features of the compressed wood pallet machine include:

Efficient Pallet Production: This molded pallet press machine is designed for high-efficiency pallet production, streamlining the process from raw material to finished product.

Customizable Specifications: Our hydraulic pallet press machine offers the flexibility to produce compressed wood pallets in various sizes and specifications, catering to different industrial needs.

Molded Pallet Pressing: Utilizing advanced molding technology, ensures precise and uniform pressing of the pallets, resulting in consistent quality.

Eco-friendly Materials: It is compatible with a range of eco-friendly raw materials, such as wood chips, sawdust, and agricultural waste, contributing to sustainable manufacturing.

Energy-efficient Operation: This wood pallet press machine is designed to minimize energy consumption during the pressing process, promoting cost savings and environmental responsibility.

Low Maintenance: Its well-engineered design and quality construction lead to reduced maintenance requirements, ensuring smooth and uninterrupted production.

High Output Capacity: The compressed wood pallet machine offers a high output capacity, meeting the demands of large-scale pallet production.

Versatile Applications: The resulting compressed wood pallets find versatile applications in industries such as logistics, manufacturing, warehousing, and transportation.

Wood Pallet Press Machine Specification

| Model | SL-WP1000 |

| Power | 15kw |

| Pressure | 1000tons |

| Capacity | Produce one pallet need 4-5 minutes(can control by yourself ) |

| Dimension | 1.9*1.3*4m |

| Weight | 21000kg |

How Do You Make Compressed Wooden Pallets?

Creating compressed wooden pallets involves the following steps:

1. Mixing Wood Particles or Flakes with Resin:

Blend wood particles or flakes thoroughly with resin to ensure strong adhesion between materials for subsequent steps.

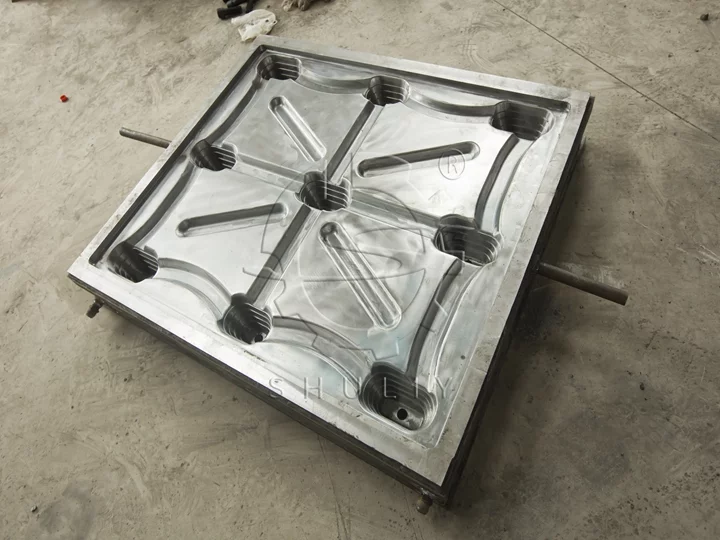

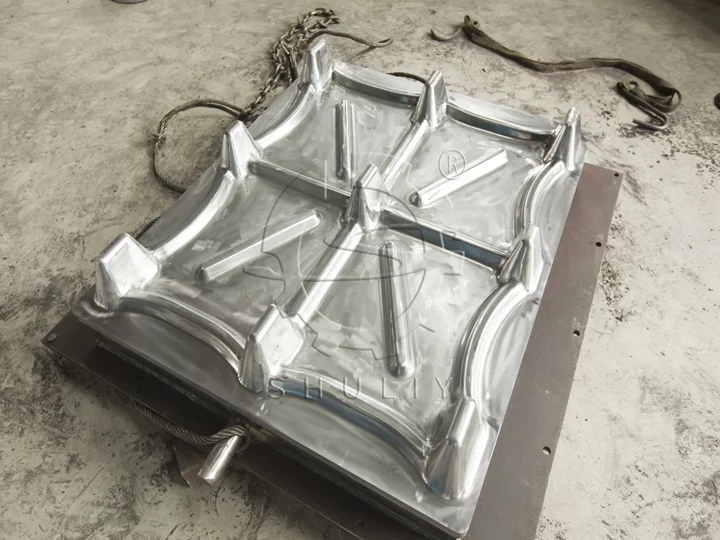

2. Forming the Mixture into Sheets Using a Mold:

Utilize molds to shape the mixture into flat sheets, applying appropriate pressure to maintain consistent shape and size.

3. Applying Heat and Pressure in a Molded Pallet Press Machine:

Subject the formed wooden sheets to heat and pressure within a specialized pallet press machine, enhancing the bond between resin and wood particles under controlled conditions.

4. Allowing the Sheets to Cure and Harden Under Controlled Conditions:

Place processed sheets in controlled environments to facilitate complete resin curing and wood hardening, enhancing the stability and durability of the pallets.

5. Trimming and Finishing the Molded Sheets to Precise Dimensions:

Trim and finish cured wooden sheets to exact specifications, ensuring smooth surfaces and precise dimensions.

6. Inspecting the Quality and Strength of the Compressed Wooden Pallets:

Conduct thorough quality and strength inspections on trimmed and finished wooden sheets to ensure compliance with relevant standards and requirements.

7. Stacking and Packaging the Pallets for Storage or Distribution:

Neatly stack and package the inspected compressed wooden pallets for convenient storage and transportation, safeguarding the products against damage during transit.

Throughout these steps, the compressed wood pallet machine plays a crucial role in efficiently molding and pressing the wooden sheets into sturdy and durable pallets, suitable for various industrial applications.

Contact Us for Wood Pallet Machine Price

Looking for the best deals on a compressed wood pallet machine? Our competitive wood pallet machine price ensures you get the right cost.

With years of expertise in the industry, we offer not just a machine, but a partnership for your success. In addition, we also offer a wood crushing machine and sawdust dryer for you.

Our dedicated team is here to guide you through the selection process, answer your queries, and provide comprehensive after-sales support. Contact us now to get the latest wood pallet machine price.

Hot Product

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Vertical Carbonization Furnace for Hardwood Charcoal Making

This vertical carbonization furnace can be used for…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a…

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…