BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ charcoal ball pressing machine

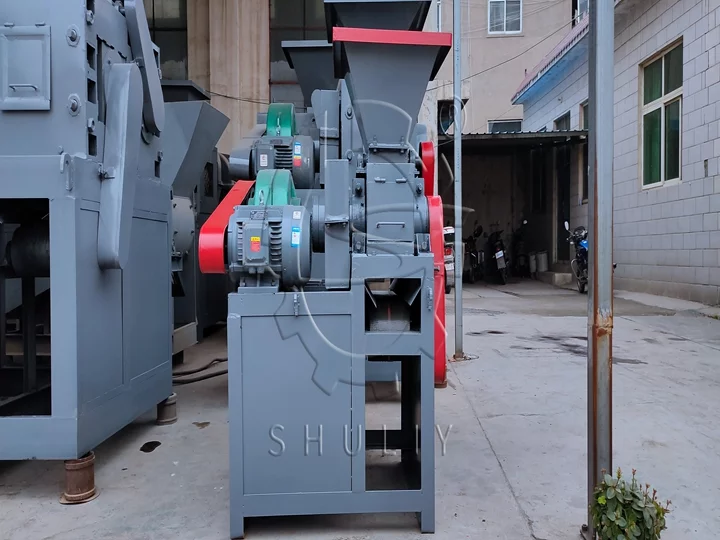

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ charcoal ball pressing machine

Features at a Glance

BBQ Charcoal Making Machine can press powdery materials, such as carbon powder and coal powder, into BBQ charcoal, which is used as barbecue fuel.

With a capacity ranging from 2 to 40 tons per hour, this machine meets the growing market demand for BBQ charcoal while offering an eco-friendly solution by reducing forest resource consumption and minimizing environmental pollution.

The finished product specifications of this BBQ Charcoal Making Machine include egg-shaped balls, oval balls, round balls, square balls, cylindrical balls, strip-shaped balls, and baguette-shaped balls. Customization is also available according to customer requirements. The general diameter is about 5 cm, with a thickness of 3 cm.

The coal ball press machine shapes materials that are energy-efficient, facilitate transport, and improve the recycling of waste, delivering significant economic and social advantages.

What are the raw materials for barbecue charcoal?

The raw materials for barbecue charcoal primarily consist of various powdered substances that can be processed into high-quality charcoal briquettes. The charcoal ball press machine is designed to handle a wide range of these materials, making it highly versatile for charcoal production.

- Coal powder

- Charcoal powder

- Coke powder

- Iron ore powder

- Aluminum powder

- Iron powder

- Magnesium dry powder

- Slag

- Gypsum

- Tailings

- Sludge

- Kaolin

- Activated carbon

Raw Material Requirements

- Particle Size: ≤1 mm accounts for 30%–40%; 1–2 mm accounts for 30%–40%; ≥3 mm accounts for about 10%.

- Moisture Content: ≤8%–10%

- Prohibited: No iron pieces or high-hardness materials allowed.

- Binder and Other Additives: (such as desulfurizers) can be added as needed.

This flexibility allows the charcoal ball press machine to efficiently convert a diverse range of raw materials into high-quality barbecue charcoal, ensuring a sustainable and cost-effective solution for barbecue fuel production.

BBQ charcoal making machine various molds

We provide various molds for producing charcoal products in different shapes. A wide range of options is available, including cubes, rounds, spheres, and more.

- Size and design flexibility. Molds come in various sizes and designs to meet different production needs.

- High-quality materials. Molds are made of durable and precise materials to ensure longevity and accurate molding.

- Customizable options. Manufacturers can produce a range of BBQ charcoal to cater to diverse market demands.

Components of the BBQ charcoal making machine

The machine is mainly composed of four parts: the feeding system, the conveying section, the forming section, and the hydraulic system.

How does the coal ball press machine work?

Feeding part

Composition

- Belt Conveyor

- Horizontal Screw Feeder (suitable for narrow rollers)

- Pre-press Screw Feeder (adjustable pressure, commonly set at 0.3–0.5 MPa

Functions

- Achieves quantitative feeding to ensure even distribution of material in the double roller space.

- The screw feeding device is driven by an electromagnetic speed-regulating motor, a belt pulley, and a worm reducer, forcing the material into the inlet.

Driving part

Composition

- Motor, v-belt, cylindrical gear reducer, exposed gears, rollers

Functions

- The driving shaft operates synchronously with the driven shaft through an open gear to ensure smooth operation.

Forming part

Composition

- Casting Rollers: Low cost, low density, loose structure.

- Forged Rollers: High density, compact structure, wear-resistant, long service life, reliable operation. Mainly used for large ball press machines, though at a higher cost.

Functions

- The core part of the machine is the double roller structure, which is responsible for shaping the charcoal.

- A hydraulic device is located behind the passive bearing seat to provide additional support.

Coal ball press machine technical data

| Model (SLYQJ) | 290 | 360 | 400 | 500 | 650 | 750 | 850 | 1200 |

|---|---|---|---|---|---|---|---|---|

| Capacity | 2-3 t/h | 4 t/h | 6 t/h | 10 t/h | 14 t/h | 17 t/h | 20 t/h | 40 t/h |

| Power | 5.5-7.5 kW | 7.5 kW | 11-15 kW | 18.5-22 kW | 30 kW | 37 kW | 45 kW | 75 kW |

| Roller Mat. | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn | 65Mn |

| Dia. of Pro. | 30-60 mm | 30-60 mm | 30-60 mm | 30-60 mm | 30-60 mm | 30-60 mm | 30-60 mm | 30-60 mm |

BBQ charcoal making machine advantages

- High forming pressure. Ensures efficient and strong compression of charcoal.

- Adjustable revolution. Allows customization of the main machine’s speed for optimal performance.

- Hydraulic protection device. Protects the machine from damage caused by overfeeding or foreign objects.

- Customizable designs. Shuliy offers various models with specific sizes and shapes of charcoal balls, and can customize machines based on user needs.

- Stable quality. The finished charcoal has a stable quality, high density, and high combustion value.

- Durable shape. The charcoal balls are not easily scattered or damaged.

- High production capacity. Capable of producing large quantities of charcoal.

- Easy operation and maintenance. Simple to operate with minimal maintenance required.

- No dust pollution. The production process is clean with no dust emissions.

Application of barbecue charcoal

- Barbecuing and grilling. The primary use of BBQ charcoal is for grilling food in outdoor settings, such as during picnics, camping, and backyard barbecues.

- Food preparation in restaurants. Widely used in restaurants for grilling meats, vegetables, and other food items, especially in barbecue or smokehouse restaurants.

- Heating. BBQ charcoal can be used as a heat source for various cooking methods, providing high and consistent heat.

- Industrial applications. Used in some industrial processes where a high, controlled heat source is needed, such as in certain metalworking or forging operations.

- Charcoal-based products. Often utilized in the production of activated charcoal, which is used for air and water purification.

- Soil enrichment. BBQ charcoal, particularly charcoal made from organic materials, is sometimes used in gardening to improve soil fertility by acting as biochar.

Why choose Shuliy’s barbecue charcoal press machine?

- Industry leader. Shuliy is the top BBQ charcoal machine supplier in China.

- Customizable solutions. Offers tailored machines to meet specific needs and enhance productivity.Certifications. ISO9001 and CE-certified with expert technical support and design guidance.

- Competitive pricing. Delivers exceptional value for money.

- Global reputation. Trusted by customers worldwide for quality and reliability.

- High-quality manufacturing. Built with precision engineering and durable materials for long-lasting performance.

- Enhanced safety features. Includes explosion-proof designs, alarm systems, and secure gas pipelines.

- Complete charcoal processing factory: Shuliy can also provide large-scale BBQ production lines to meet higher output requirements.

Precautions for using the charcoal ball press machine

- It is strictly forbidden for hard objects such as iron blocks or stones to enter the machine; any damage caused will be the user’s responsibility.

- The processed material should have a particle size of ≤3 mm, otherwise the machine’s lifespan may be affected.

- Do not start the machine under heavy load.

- Perform regular maintenance and check whether the reducer and bearing seats have sufficient lubrication.

Customer success case

In May 2025, we successfully exported a charcoal ball press machine to a customer in Thailand who owns a wood processing factory. The machine, with a processing capacity of 1–2 tons per hour and equipped with a conveyor, efficiently converted carbonized wood shavings into high-quality barbecue charcoal balls. The customer was highly satisfied, noting excellent output, high raw material utilization, easy operation, and stable performance. This project not only enhanced the customer’s economic value but also demonstrated Taizy’s expertise in providing customized, efficient, and environmentally friendly new energy machinery solutions.

Conclusion

In conclusion, the BBQ charcoal making machine is an efficient and reliable solution for producing high-quality barbecue charcoal to meet market demands.

In addition to this machine, our company also offers a wide range of charcoal processing equipment, including shisha charcoal machines, charcoal briquette machines, and carbonization furnaces.

We invite you to contact us for inquiries and explore how our comprehensive solutions can support your business needs.

F&Q

What is the production line process, and what is the difference between coal powder and charcoal powder?

The mixers are different, and the binders are different.

Can the size of the ball press machine be customized?

Yes.

What are the shapes of the pressed balls?

Standard spherical, pillow-shaped, and oval-shaped.

What are the accessories of the ball press machine?

Press rollers, which have a long service life.

Can it press sawdust?

Yes, but a dry powder ball press machine with high pressure is required.

What is the moisture content of the finished product?

About 20%.

Is there a four-roller ball press machine?

The standard is two rollers; for models above 360, four rollers can be made.

What is the standard size of a single ball?

5 cm in diameter and 3 cm in thickness.

Charcoal Production Line Machine

The Charcoal Production Line Machine by our company offers a…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality shisha charcoal…

Charcoal briquette press machine exported to Iraq

Recently, our charcoal briquette press machine has successfully been sold…

Hookah charcoal making machine sent to Jakarta

As a leading supplier of hookah charcoal making machines, we…

Two vertical carbonization furnaces shipped to myanmar

Good news! Our vertical carbonization furnaces have been successfully shipped…

Hot Product

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Shisha Charcoal Packing Machine

Our shisha charcoal packing machine is an important…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Sawdust Briquette Making Machine | Biomass Briquette Machine

The sawdust briquette making machine is an environmentally…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…