Coal Briquette Machine | Honeycomb Coal Press Machine

test

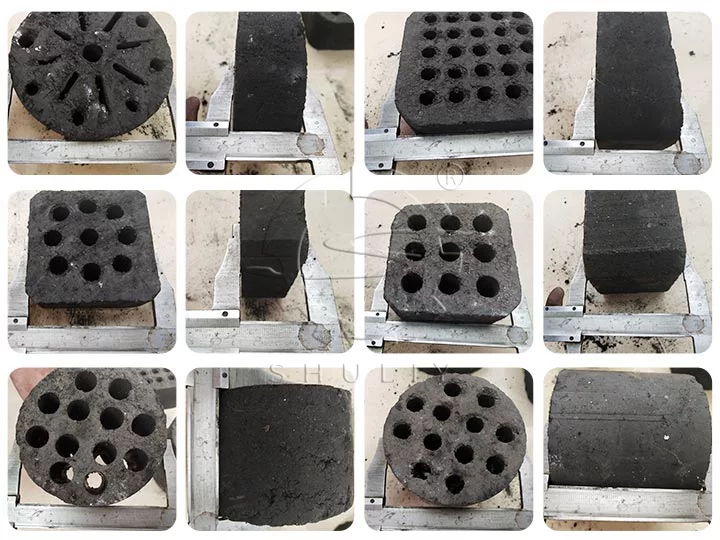

Coal briquette machine can produce different shape and sizes of final briquettes, including round, oval, square, or rectangular, etc. And Shuliy will offer you honeycomb coal press machine with customized options and attractive prices. Sending an inquiry to Shuliy is the right decision.

What Is a Coal Briquette Machine?

A coal briquette machine is also known as or a honeycomb coal press machine. It can press coal powder into a specific shape or size to be used for various purposes. The main purpose of using a coal briquette machine is to reduce dust pollution, control the volume of storage, and improve the transportation characteristics of the coal.

Final Briquettes Produced by Coal Briquette Machine

The final briquettes are solid and compact fuel blocks with a specific shape or size, depending on the type of briquette machine used and the desired end product. The resulting briquette can be used as a fuel in industrial boilers, power plants, or domestic stoves.

- Shape and Size: The briquettes can have various shapes, such as round, oval, square, or rectangular, and they can also be customized based on the specific requirements of the customer or the intended application.

- High Density: The briquettes have a high density, which means they are tightly compacted and have a reduced volume compared to the original coal powder or dust. This high density makes the briquettes easier to store, transport, and handle.

- Versatility: The coal briquette machine can process not only coal but also other materials like charcoal, coke, carbon black, and various mineral powders. This versatility allows for the utilization of different feedstocks to produce a wide range of briquette products.

Shuliy Coal Briquette Machine for Sale

| Model | Power | Maximum diameter of charcoal |

| SL-HC120 | 5.5kw | 120mm |

| SL-HC140 | 7.5kw | 140mm |

| SL-HC160 | 11kw | 160mm |

| SL-HC220 | 11kw | 220mm |

How Does the Honeycomb Coal Press Machine Work?

It has several components, including a feeding hopper, a screw propeller, a heating coil, and a forming mold. The coal powder is fed into the machine through the hopper, and the screw propeller pushes the coal forward while applying pressure.

The heating coil generates heat to melt the lignin present in the coal, which acts as a binder. The softened coal is then forced through the forming mold, where it takes on the desired shape. Finally, the formed briquettes are discharged from the machine and can be collected for further use.

Why Send an Inquiry to Shuliy?

Sending an inquiry to Shuliy is the right decision because we are a trusted manufacturer with years of experience in the industry. Moreover, we provide comprehensive after-sales service and technical support to ensure your satisfaction with our products.

We offer a wide range of coal briquette machines, including honeycomb coal press machines, all of which are available for sale at competitive prices.

Whether you need one for small-scale or large-scale production, Shuliy Machinery can offer you the right solution. Don’t hesitate to contact us for more information and price.

Hot Product

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…

Vertical Carbonization Furnace for Hardwood Charcoal Making

This vertical carbonization furnace can be used for…

Rice Husk Drying Machine | Rotary Dryer for Sale

Our rice husk drying machine, or a rotary…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Shisha Charcoal Packing Machine

Our shisha charcoal packing machine is an important…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…