How to Choose the Right Hookah Charcoal Tablet Press Machine? – A Full Guide to 3 Popular Models

As the global hookah market continues to grow, the demand for hookah charcoal is rising as well. Choosing the right hookah charcoal tablet press machine can help improve production efficiency, ensure product quality, and reduce labor costs.

With so many machines on the market, how do you know which one is best for your needs?

In this article, we’ll introduce three of the most popular hookah charcoal machines. You’ll learn about their main features, how they work, and which situations they are best suited for—helping you make the right choice for your business.

Types of Hookah Charcoal Tablet Press Machines

There are three main types of hookah charcoal press machines commonly used in the market:

- Hydraulic Hookah Charcoal Press Machine

- Rotary Tablet Press Machine

- Stainless Steel Hookah Charcoal Machine

Type 1: Hydraulic Hookah Charcoal Press Machine

Features

- Uses a hydraulic system for strong and even pressure.

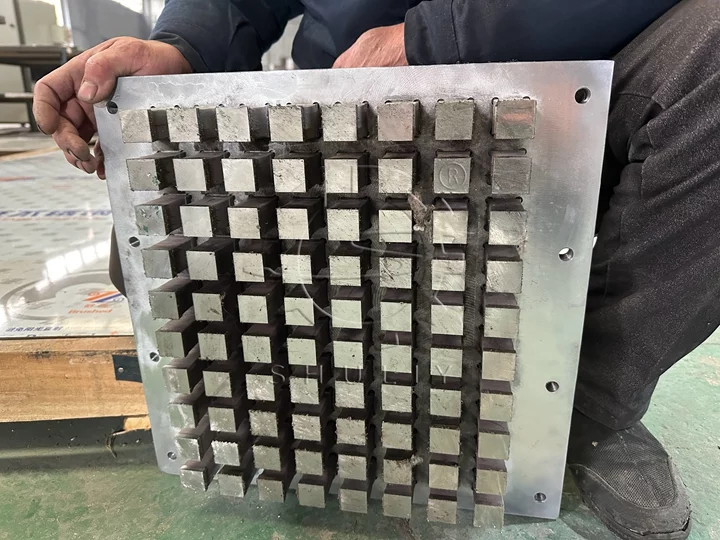

- Supports various mold shapes: round, square, teardrop, hexagon, etc.

- Custom logo molds available – ideal for branded production.

- Easy to operate, simple maintenance, and cost-effective.

- Automatic demolding for efficient production.

- Suitable for pressing coconut shell charcoal powder, fruitwood charcoal powder, and more.

Application

- Small to medium-sized hookah charcoal factories

- Individual entrepreneurs or small business owners

Disadvantages

- Usually single-punch, so output is relatively low.

- Not ideal for large-scale or continuous production.

Conclusion

If you’re new to the hookah charcoal business or don’t need high output, a hydraulic press is a great entry-level choice. It requires low investment, is easy to use, and is perfect for small workshops or home-based factories.

Type 2: Rotary Hookah Charcoal Tablet Press Machine

Features

- Multi-station rotary mold design enables continuous automatic pressing.

- Automatic feeding system ensures high production efficiency—daily output can reach tens of thousands of tablets.

- Adjustable pressure for consistent density and smooth surface.

- It can be connected with automatic drying and packing lines to form a fully automated production line.

- Supports custom flat tablet shapes: round, special shapes, double-layer, ring-shaped, etc.

- Suitable for pressing granulated materials into various tablet forms.

- Easily customizable tablet diameter from 25mm to 35mm.

Application

- Medium to large-scale hookah charcoal manufacturers

- Businesses with high-volume production needs and stable customer orders

Disadvantages

- Higher investment cost

- Larger footprint, requires suitable production space and power supply

Conclusion

If you have steady customer orders or export needs, the rotary press is a smart choice. It significantly boosts production capacity and product consistency while saving labor—perfect for large-scale, automated operations.

Type 3: Stainless Steel Hookah Charcoal Press Machine

Features

- Made entirely of stainless steel – easy to clean, corrosion-resistant, and durable.

- Sleek and premium appearance, ideal for high-end markets.

- Designed for countries/regions with strict hygiene requirements.

- Suitable for product displays and export certification needs.

- Can produce both round and square charcoal tablets.

Application

- Export-focused businesses

- High-standard factories

- Users requiring a clean and hygienic production environment

Disadvantages

- Slightly higher cost than regular models

- Similar in function to hydraulic or rotary presses, its advantage lies in material and design quality.

Conclusion

If you’re targeting markets like the Middle East, Europe, or North America—where hygiene and machine material standards are important—this stainless steel machine is easier to certify and helps enhance your brand image.

Want to Learn More About Hookah Charcoal Equipment or Custom Mold Services?

Feel free to contact us anytime for the latest price, factory videos, overseas cases, and technical details. We’ll recommend the most suitable production solution based on your budget and capacity needs.