Shisha Charcoal Packing Machine

Hookah charcoal packing machine | pillow wrapper machine

Shisha Charcoal Packing Machine

Hookah charcoal packing machine | pillow wrapper machine

Features at a Glance

Our shisha charcoal packing machine is an important equipment in the hookah shisha charcoal production line. This pillow wrapper machine, namely horizontal flow wrap machine, is designed to efficiently package shisha charcoal products using a pillow-style wrapping technique. It carefully encases the shisha charcoal, providing protection and a polished appearance. This charcoal briquettes packing machine has many benefits for you, such as easy operation, factory price, and more. For more information, quotes, and customized solutions, get in touch with us now.

Application of Shisha Charcoal Packing Machine

The Shisha charcoal packing machine, also known as the pillow wrapper machine, is a crucial tool for efficiently packaging Shisha charcoal products. It streamlines the packaging process, ensuring the neat and professional presentation of Shisha charcoal in various packaging styles.

This machine offers a practical solution for businesses in the Shisha industry to package their products securely and attractively, enhancing their marketability and customer satisfaction. You can use it to pack round or cube hookah charcoal. In addition, we can design outer packaging with your logo, color and more to enhance your reputation.

Benefits of Hookah Charcoal Packing Machine

1. Smart Design: The hookah charcoal packing machine boasts an excellent design, ensuring smooth and hassle-free operations.

2. User-Friendly: With a simple structure, it’s easy to operate, making it perfect for both beginners and experienced users.

3. Stability Matters: The machine guarantees stable performance, reducing any chances of interruptions during packaging.

4. Intelligent Control: Equipped with a PLC intelligent control system, it offers user-friendly control options and can be easily upgraded as needed.

5. Safety First: Safety is a priority, with reliable safety protection devices to ensure the well-being of operators during its use.

6. Precise Performance: Featuring a servo motor system, it performs with precision and high efficiency, saving time and resources.

7. Temperature Control: An independent temperature PID control system adapts to various film materials, guaranteeing accurate packing.

8. Low Noise: It operates with minimal noise levels, providing a comfortable working environment and minimizing disturbances.

9. Energy Efficient: The machine is designed to be energy-saving, helping your operations stay eco-friendly and cost-effective.

10. Affordable Choice: With a competitive factory price, this charcoal briquettes packing machine offers exceptional value for its quality and features.

Shisha Charcoal Wrapping Machine Parameters

| Model | TH-250B | TH-250D | TH-250S |

| Film width | Max.250mm | Max.250mm | Max.180mm |

| Bag length | 65~190mm 120~280mm | 90~220mm | 45 ~ 90mm |

| Bag width | 30~110mm | 30~110mm | 30 ~ 80mm |

| Product height | Max.40mm | Max.55mm | Max.35mmn |

| Film roll diameter | Max.320Tm | Max.320Tm | Max.320Tm |

| Packaging speed | 40-230Package/min | 40-230Package/min | 60-330Package/min |

How to Pack Shisha Charcoal with Pillow Wrapper Machine?

Packing shisha charcoal is made easy with the innovative shisha charcoal packing machine, also known as shisha charcoal packaging equipment. This machine concise the packaging process by efficiently wrapping your shisha charcoal products using a pillow wrapper technique.

Simply place the shisha charcoal into the designated area, and the machine will automatically seal and wrap the product in a neat and secure pillow-like package. This method not only enhances the presentation of your shisha charcoal but also ensures their protection during storage and transportation.

With the shisha charcoal packing machine, you can achieve efficient and consistent packaging, contributing to the overall success of your shisha charcoal business.

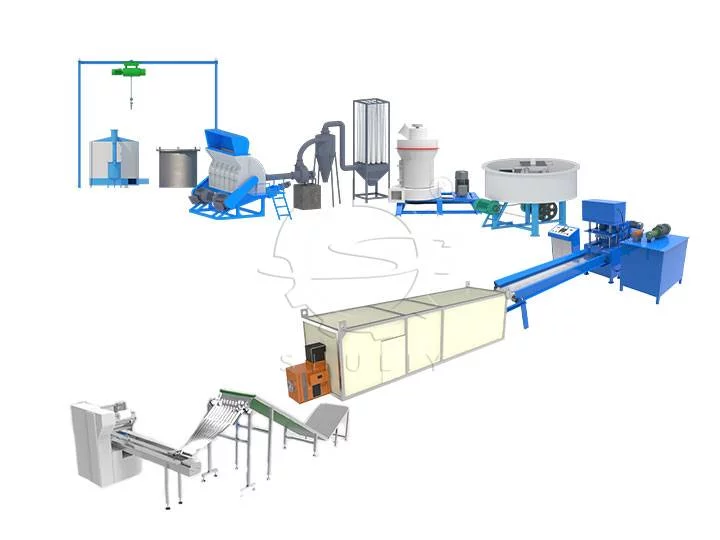

Pillow Wrapper Machine in Shisha Charcoal Production Line

The pillow wrapper machine is a crucial component in the shisha charcoal production line. This specialized machine is designed to efficiently package shisha charcoal products using a pillow-style wrapping technique. It carefully seals and encases the shisha charcoal, ensuring their protection and enhancing their presentation.

In the complete shisha charcoal production line, you will find a range of machines working together to complete the process. These include a shisha charcoal making machine, charcoal grinder, binder mixer, charcoal briquette machine,cutter, charcoal drying box,, and the shisha charcoal packing machine for the final packaging.

Contact us now to learn more about our shisha charcoal packing machine and how it can enhance your production process. For more information, pricing details, and customized solutions, please don’t hesitate to get in touch with us.

Hot Product

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Coal Briquette Machine | Honeycomb Coal Press Machine

Coal briquette machine can produce different shape and…

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…