What is the continuous carbonization process?

Continuous carbonization process is a modern method of converting biomass (like sawdust, rice husks, coconut shells, bamboo, straw, nutshells, etc.) into charcoal (such as machine-made charcoal or activated carbon) and combustible gases. This is done by heating the materials at high temperatures in a low-oxygen or oxygen-free environment.

To meet the needs of large-scale and automated charcoal production, Shuliy Machinery has carefully developed and launched the Continuous Carbonization Furnace. This machine features a sealed design, with continuous feeding and discharging, making it ideal for the efficient carbonization of various biomass materials. It is widely used for processing sawdust, rice husks, coconut shells, nutshells, crop stalks, and more, turning waste into valuable resources.

This process is centered on stable high-temperature pyrolysis, combined with intelligent control, heat recovery, and exhaust gas purification technologies. Together, they form an eco-friendly, efficient, and highly automated charcoal production solution.

Compared with traditional batch carbonization, the continuous carbonization process offers significant advantages in energy efficiency, environmental protection, and output capacity.

Key Features of the Continuous Charcoal Carbonization Furnace

Continuous Feeding & Discharging

Raw materials are fed and discharged automatically, supporting uninterrupted, large-scale production.

Sealed and Safe Design

The entire carbonization takes place in a closed chamber, reducing smoke, gas leakage, and fire risks.

Energy Efficient

The combustible gas produced during carbonization is reused as fuel, lowering external energy costs.

Smart Control System

Equipped with automated temperature control and feeding systems for precise operation.

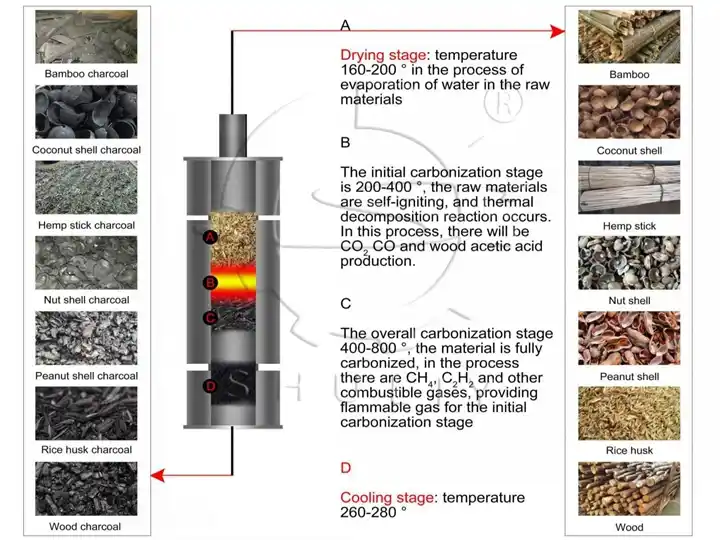

Carbonization Process Flow

Raw Material Preparation

- Crushing: Materials larger than 15 cm need to be crushed.

- Drying: Moisture content should be below 15% for optimal results.

- Feeding: Use screw conveyors or belt conveyors to load materials into the furnace.

High-Temperature Carbonization (400–800°C)

The biomass undergoes pyrolysis, breaking down into charcoal and gases:

- Drying Zone (160–200°C): Moisture evaporation

- Pyrolysis Zone (200–400°C): Organic matter begins to decompose

- Carbonization Zone (400–800°C): Charcoal forms, and gas is released

- Cooling Zone (260–280°C): Prevents re-ignition

Combustible Gas Recovery & Reuse

Gases like CO, H₂, and CH₄ are cleaned and reused for heating, reducing the need for extra fuel.

Charcoal Cooling & Discharging

A cooling system (screw or water cooling) brings down the charcoal temperature. Finished charcoal is then automatically discharged.

Exhaust Gas Treatment

Exhaust gases are filtered, condensed, and purified before being safely released, meeting environmental standards.

Advantages of the Continuous Carbonization Process

- High Output: Daily capacity can reach several tons—ideal for industrial use.

- Low Energy Consumption: Uses its own gases for heating.

- Eco-Friendly: Clean emissions with no visible smoke or strong odor.

- Fully Automated: Less manual work, safer operation, consistent quality.

- Wide Application: Handles various agricultural, forestry, and industrial organic wastes.

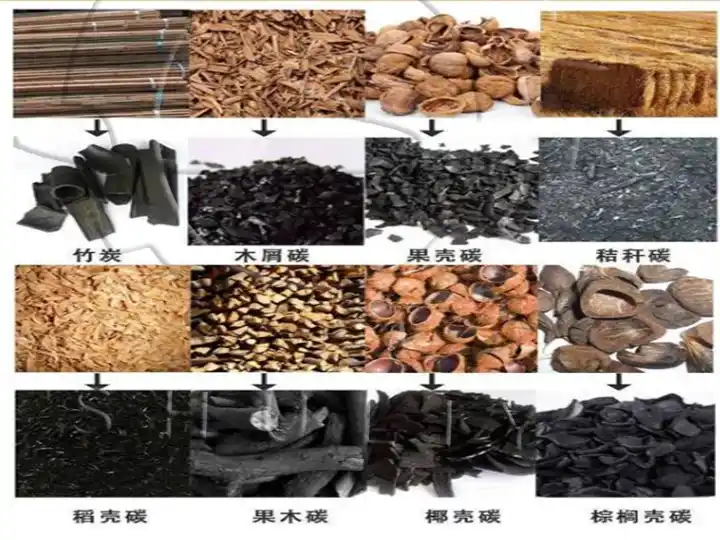

Suitable Raw Materials

- Biomass (e.g., sawdust, peanut shells, corn stalks, rice husks)

- Agricultural Waste (e.g., sugarcane bagasse, sorghum stalks, cotton stems)

- Forestry Waste (e.g., bamboo, tree branches, palm shells)

- Other Organic Waste (e.g., distiller’s grains, corn cobs, dry leaves)

- Industry By-products (e.g., coffee grounds, apricot shells, herbal residue)

- Various Plant Stems (e.g., sunflower shells, yam vines, hemp stalks)

- Urban Sludge & Paper Mill Waste (requires pre-treatment)

- Industrial Organic Waste (after dehydration and crushing)

Equipment Recommendation

Model: SL-CF1200

Diameter: 1200mm

Capacity: 1200-2000 kg/h

Main Power: 20kw

Carbonization Temperature: 500-800℃

Fan Power(kw): 5.5kw

Production date: 20 working days

Transportation: By sea

Application Fields

- Machine-made charcoal production: For BBQ charcoal, heating fuel, etc.

- Pre-carbonization of activated carbon materials

- Carbon-based fertilizer manufacturing

- Waste-to-resource utilization: Harmless carbonization of agricultural straw and municipal waste

- Carbon sinks and carbon trading: Carbon sequestration to support carbon peaking and neutrality