Wood Comprehensive Crusher | Wood Pallet Shredder

Wood pallet crusher

Wood Comprehensive Crusher | Wood Pallet Shredder

Wood pallet crusher

Features at a Glance

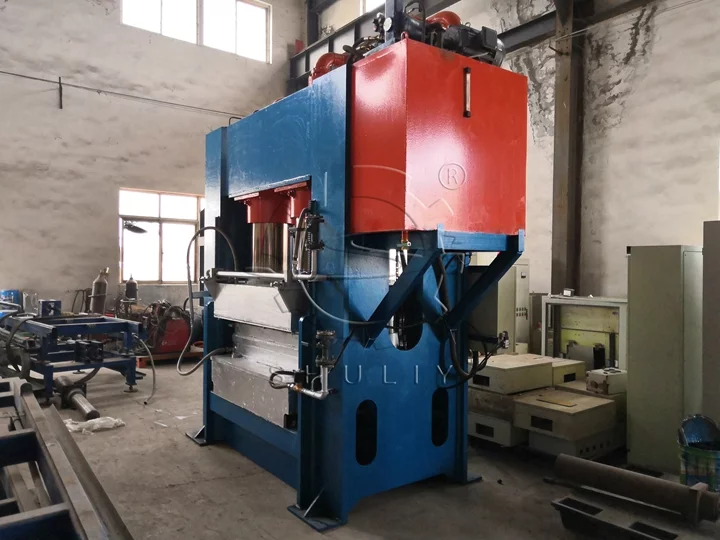

The wood comprehensive crusher, commonly known as a wood pallet shredder, is a large and medium-sized primary wood processing machine. It is designed to crush wooden pallets, logs, branches, bamboo, construction templates, supports, nail-containing boards, tree roots, weeds, and waste furniture into wood chips smaller than 100 mm. The production capacity can reach 8–30 tons per hour.

The equipment can be matched with conveyor systems of different lengths, offering a wide range of applications. It can also be equipped with a magnetic roller to completely remove nails and other metal impurities from the wood chips, ensuring the final product is free of metal. Therefore, this machine is especially suitable for industries such as wood recycling, wood pallet crushing, and waste furniture shredding.

Its versatility in handling various wood materials, coupled with its ability to manage mass wood waste efficiently, has made it a favored solution among industries worldwide, including in Canada, Malaysia, and Brazil.

What materials can the wood pallet shredder process?

The wood pallet shredder is a highly versatile machine engineered to efficiently process a broad range of wood-based materials, making it an essential tool in waste management and recycling operations.

Materials that can be processed:

- Agricultural residues and straw: Such as crop stalks, rice straw, grain husks, and leftover materials produced during the handling or processing of agricultural products.

- Forestry and timber waste: Including tree branches, roots, leaves, sawdust, wood shavings, and other by-products from logging or wood processing operations.

- Discarded wood materials and pallets: Such as old formworks, nail-containing construction boards, waste wooden furniture, pallets, and pallet frames of different sizes.

- Additional capabilities. It can also process wooden boards, planks, and scrap wood from construction or manufacturing sites, accommodating different wood compositions and sizes.

The adaptability of the wood comprehensive crusher makes it a valuable asset for businesses looking to optimize their waste management processes and contribute to recycling efforts.

Application of wood comprehensive crusher

The wood pallet shredder is extensively utilized across various industries that generate substantial wood waste. It is a crucial tool for efficient waste management. Industries such as logistics, warehousing, manufacturing, and construction benefit greatly from its capabilities.

The shredder efficiently processes a wide range of wood materials, including wooden pallets, crates, packaging materials, and even large timber pieces.

- Industry applications. The shredder is indispensable in sectors like logistics, warehousing, and construction, where it handles large volumes of wood waste, including pallets, crates, and wooden packaging materials.

- Versatile processing. It effectively reduces large pieces of timber and other wood materials into manageable sizes, optimizing waste disposal and recycling processes.

- Secondary uses. The shredded wood produced by this machine can be repurposed in various ways. It can be processed into biomass fuel, used in the production of particleboard, converted into animal bedding, or serve as a raw material for composite materials, contributing to sustainable practices.

By integrating the wood pallet shredder into their operations, businesses not only enhance their waste management efficiency but also contribute to the creation of valuable recycled products.

Specifications of the wood comprehensive crusher

| Model | SL-1300 | SL-1400 | SL-1600 |

| Feeding inlet size | 1300*500mm | 1400*800mm | 1600*800mm |

| Feeding maximum diameter | 400mm | 500mm | 600mm |

| Output size | Less than 100mm | Less than 100mm | Less than 100mm |

| Input conveyor | 6m | 6m | 6m |

| Output conveyor | 8m | 10m | 10m |

| Blades(pcs) | 20 | 32 | 66 |

| Capacity | 8-10 t /h | 10-15t/h | 20-30t/h |

| Total power | 156.5kw | 213.5kw | 233.5kw |

| Overall size | 8600*2000*2300mm | 9600*2400*3300mm | 12500*2800*3200mm |

Our machines are available in various specifications to meet the diverse needs of different industries. The specifications may include parameters such as motor power, shredding capacity, feeding size, and dimensions. From Shuliy, you will find the right one for your business.

Main features of the wood comprehensive crushing machine

It is equipped with several features that contribute to its efficient and reliable operation. Many customers chose our machine and got great performance.

Foundation-free design for easy installation

The machine adopts a foundation-free structure, allowing direct installation without concrete bases. Compared to traditional crushers, installation time can be reduced by 40%, saving labor and construction costs.

Fully automatic intelligent control

Equipped with a PLC automatic control system, the entire process of feeding, crushing, and discharging is automated. This reduces safety risks caused by manual operation and improves operational efficiency.

High-efficiency crushing & smooth feeding

The optimized feeding system combined with multi-blade design ensures smooth material feeding without clogging.

- Multi-alloy blades improve crushing efficiency by 20–30%;

- Uniform output size, maximum ≤100 mm, suitable for pelletizing or fuel production.

Wide material compatibility

Capable of processing bamboo, wooden pallets, rubber boards, waste furniture, and more. Even nailed wood pallets can be crushed directly without disassembly. The blades are highly durable, preventing damage from metal impurities.

Hydraulic system for easy maintenance

The hydraulic-opening design of the machine housing allows blade inspection and replacement in just a few minutes, improving maintenance efficiency by 50% and minimizing downtime.

Adjustable discharge system

The discharge direction can be adjusted to the left, right, or rear according to the plant layout, providing flexible operation and optimal space utilization.

Durable structure & wear-resistant materials

The machine body is made of thick, welded carbon steel, with high-temperature hardened blade discs and main shafts to ensure stable operation under heavy load. Service life can reach over 10 years.

Integrated monitoring system for safety

Built-in monitoring displays key parameters such as speed, current, and temperature in real time. Early warnings prevent faults, ensuring safe and continuous operation.

Machine structure

The wood comprehensive crusher consists of a feed conveyor, crushing saws (blade type for nail-free wood and claw type for nailed materials), pressure rollers, a screening system, and a discharge conveyor.

How does the wood pallet crusher work?

The wood pallet crusher operates primarily through the use of impact energy to effectively break down wood materials. Here’s how it works.

- High-speed rotation. The crusher’s motor drives the rotor to rotate at high speed. As the wood enters the crushing chamber, it encounters the rapidly rotating hammerhead.

- Impact crushing. The hammerhead, moving at high velocity, strikes the wood with significant force. This impact is the primary mechanism that causes the wood to break apart.

- Gravity assistance. In addition to the impact from the hammerhead, the weight of the wood itself contributes to the crushing process. This combination ensures a thorough material breakdown.

- Screening process. The crushed wood is then passed through a screen located at the bottom of the crusher. Wood pieces that are smaller than the screen size are discharged, while larger pieces remain inside.

- Continued crushing. Larger wood pieces that do not pass through the screen continue to be struck and ground by the hammers until they reach the appropriate size and can pass through the screen for discharge.

Why choose to buy our comprehensive wood crusher?

Selecting a reliable and reputable supplier is essential for effective wood waste management. Our comprehensive wood crushers offer several advantages that set them apart from the competition.

- Durability and efficiency. Our crushers are built to last, featuring robust construction that ensures long-term performance and reliability. They are designed for efficient operation, reducing downtime and maintenance costs.

- Wide range of models. We provide a diverse selection of models to meet various customer needs. Whether you require a machine for small-scale operations or large industrial processes, we have a solution tailored to your requirements.

- Advanced technology. Equipped with cutting-edge technology, our wood crushers handle a broad range of wood materials, from pallets to large timber, providing versatility and efficiency in wood waste processing.

- Excellent customer support. Our dedicated team of experts offers exceptional customer service, assisting you in selecting the right machine and providing ongoing support to ensure optimal performance.

Choosing our comprehensive wood crushers means investing in high-quality machinery backed by expert support. Contact us today for pricing and to explore how our solutions can improve your wood waste management processes.

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process various wood…

Wood Hammer Mill | Hammer Mill Shredder

The wood hammer mill adopts a hammer and screen system…

Wood Shavings Machine | Log Shavings for Animal Bedding

The wood shaving machine can efficiently cut logs, branches, and…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chippers are designed to handle a wide range…

Wood Pallet Block Making Machine

The wood pallet block making machine, also known as a…

Wood Debarking Machine | Log Peeling Machine

Wood debarking machine, also known as a log peeling machine,…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for sale. You…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Sawdust Briquette Making Machine | Biomass Briquette Machine

The sawdust briquette making machine is an environmentally…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Rice Husk Drying Machine | Rotary Dryer for Sale

Our rice husk drying machine, or a rotary…