Animal Feed Pellet Machine | Pellet Feed Mill Machine

Feed pellet mill | Cattle feed making machine

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Feed pellet mill | Cattle feed making machine

Features at a Glance

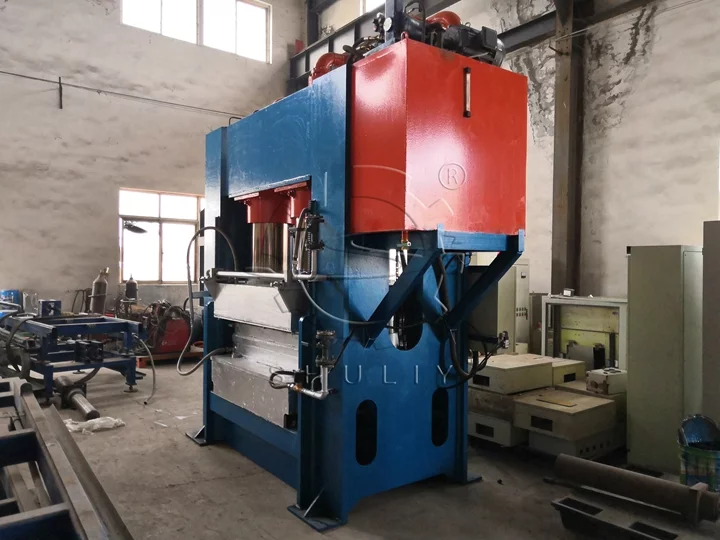

Shuliy offers the animal feed pellet machine for sale. You can also name it a pellet feed mill, or feed pelletizer machine. It can adopt various raw materials to produce animal feed pellets.

From here, you will know the price range and advantages of this equipment. And contact us, you will get the right one for your business.

What Is Animal Feed Pellet Machine?

The animal feed pellet machine, also known as a feed pellet mill, or feed pelletizer machine, is a specialized piece of equipment used in the animal feed production process.

It will compress and shape various raw materials into high-quality feed pellets suitable for different types of animals, such as poultry, livestock, and pets.

Raw Materials for Animal Feed Pellet Machine

The raw materials used in the animal feed pellet machine are diverse and can vary based on the nutritional requirements of different animal species.

Some common raw materials include grains (corn, wheat, barley, oats), oilseeds (soybean, sunflower, canola), protein-rich sources (fish meal, soybean meal, cottonseed meal), and various agro-industrial by-products (rice bran, wheat bran, corn gluten feed).

Grains serve as the primary energy source in animal feed, providing carbohydrates and essential nutrients. Oilseeds, on the other hand, are valuable sources of fats and proteins, contributing to the overall nutritional profile of the feed. Protein-rich sources such as fish meal and soybean meal are critical for meeting the protein requirements of animals, supporting growth and development.

Incorporating agro-industrial by-products like rice bran and wheat bran into the feed helps reduce waste and adds supplementary nutrients to the diet. These by-products are often rich in fiber and minerals, offering additional benefits for animal health.

Working Principle of Feed Pelletizer Machine

The main components of an animal feed pellet machine include a feeding hopper, a conditioner, a pellet die, and a roller assembly. The raw materials are fed into the machine through the hopper.

Inside the machine, the raw materials are conditioned with steam and moisture to improve their plasticity and gelatinization properties. This conditioning process ensures the formation of durable and nutritious pellets.

The pellet dies and roller assembly plays a crucial role in shaping the feed pellets. The raw materials are forced through the small holes of the pellet die under high pressure, and the rotating rollers compress them into cylindrical or spherical shapes.

Customized feed pellet making machine

The size of the pellet holes and the speed of the rollers can be adjusted to produce pellets of different diameters and lengths to meet the specific nutritional requirements of different animal species.

By using a combination of these raw materials and processing them through the animal feed pellet machine, feed manufacturers can produce high-quality pellets tailored to meet the specific dietary needs of various animal species.

This enables farmers to provide their animals with a balanced and complete diet, leading to improved performance and overall health.

Specifications of Animal Feed Pellet Machine

| Model | Power | Output | Dimension |

| SL-F-125 | Single phase, 4kw | 80-100kg/h | 850*350*520mm |

| SL-F-150 | Single phase, 4kw | 100-150kg/h | 850*350*570mm |

| SL-F-210 | Three phase, 7.5kw | 300-450kg/h | 990*430*710mm |

| SL-F-260 | Three phase, 11/15kw | 600-800kg/h | 1300*450*1100mm |

| SL-F-300 | Three phase, 22kw | 1000-1200kg/h | 1360*570*1150mm |

| SL-F-400 | Three phase, 30kw | 1500-1800kg/h | 1550*620*1250mm |

Features of Pellet Feed Mill Machine

The pellet feed mill machine is a crucial equipment in the animal feed production process. Several features make the animal feed pellet machine stand out as an essential tool for feed manufacturers and farmers alike.

- Efficient Pelletizing Process: It compresses the feed materials under high pressure, creating dense and uniform pellets that have consistent nutritional content. This feature allows for better nutrient absorption by animals, leading to improved feed conversion rates and enhanced animal performance.

- Versatility in Raw Material Processing: It can handle a wide range of raw materials, including grains, oilseeds, protein sources, and others. This versatility allows feed manufacturers to formulate balanced and nutritious diets based on the specific nutritional requirements of different animal species.

- Customizable Pellet Size: Feed manufacturers can easily adjust the machine settings to produce pellets suitable for different animal age groups and feeding stages. This flexibility enables precise feed formulation, ensuring that animals receive the right nutrients at each life stage.

- Enhanced Feed Digestibility: The pelleting process improves the digestibility of the feed, as the pellets have reduced particle size and increased surface area compared to loose feed ingredients. This enhanced digestibility results in better nutrient utilization by animals, leading to reduced feed wastage and improved feed efficiency.

- Improved Feed Handling and Storage: Pellets produced by the feed mill machine have higher density and lower moisture content, making them easier to handle, transport, and store. The compact nature of pellets reduces the risk of feed spoilage.

- Cost-Effective and Sustainable: The efficient pelleting process leads to reduced feed wastage and improved feed conversion rates, making animal production more cost-effective and environmentally friendly.

What Is the Price of Small Pellet Machine?

The price of a small animal feed pellet machine typically ranges from 50,000 to 65,00,000 Indian Rupees (INR). When converted to US Dollars (USD), the price range would be approximately $700 to USD 9,000.

Small feed pelletizer machines, with lower capacities and fewer advanced features, tend to be more budget-friendly, while larger, high-capacity machines with advanced automation and control systems will be on the higher end of the price range.

For those interested in purchasing a small animal feed pellet machine, it is recommended to carefully consider their specific needs and production requirements before making a decision.

The Process of Making Animal Feed Pellets

The process of making animal feed pellets involves two main steps. First, the raw materials are ground and mixed to form a consistent feed mixture. Second, the feed mixture is compressed and shaped into pellets using a pellet mill.

- Raw materials are collected and mixed to achieve the desired nutritional composition.

- The mixed raw materials are then ground into a fine powder using a hammer mill or a similar grinding machine.

- The ground materials are passed through a feed pellet machine, where they are compressed and shaped into pellets under high pressure and temperature.

- A conditioner may be used to add steam and moisture to the pelletizing process, improving pellet quality and palatability.

- The freshly formed pellets are then cooled down to reduce their temperature and moisture content, enhancing their storage stability.

- After cooling, the animal feed pellets are screened to remove fines and ensure uniform size and shape.

Contact us!

Our Animal Feed Pellet Machine offers high-quality, efficient, and cost-effective feed production solutions.

Whether for small farms or large-scale operations, our customizable machine ensures optimal performance and longevity.

Contact us today for a personalized consultation and competitive quote to enhance your feed production process!

Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a wood pallet…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process various wood…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips, straw, waste…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes wood to…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution for processing…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and various other…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log Peeling Machine,…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Charcoal Briquettes Packing Machine for Barbecue Charcoal

Our charcoal briquettes packing machine, namely BBQ charcoal…

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Shisha Charcoal Packing Machine

Our shisha charcoal packing machine is an important…