Drum Style Wood Chipper

Drum Style Wood Chipper

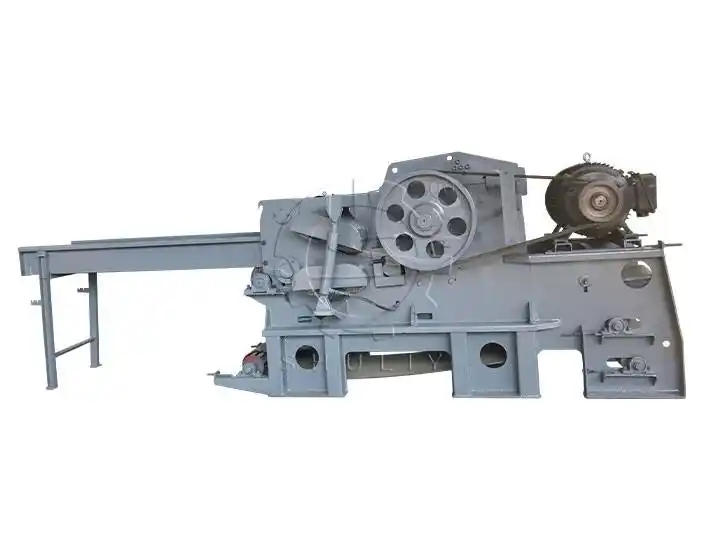

A drum style wood chipper is an efficient machine used in the wood processing industry to convert large wood logs or branches into high-quality wood chips or sawdust. The machine’s central component is a cylindrical drum with cutting blades or knives arranged along its surface.

As the drum rotates, it draws in the wood material and cuts it into smaller pieces, producing consistent wood chips with high efficiency and precision. Drum style wood chippers are widely used in various industries, including forestry, woodworking, and biomass processing.

This drum wood chipper has a capacity of 10–15 tons per hour, suitable for large-scale production.

We provide a comprehensive overview of the drum style wood chipper machine, covering its functionality, raw material usage, technical specifications, advantages, and key differences compared to disc chippers.

Raw Material of Drum Style Wood Chipper

Drum style wood chipper is capable of processing a wide range of raw materials, including tree branches, logs, slab wood, waste lumber, and other wood residues.

The wood chips making machine is specifically designed to handle various wood sizes and shapes, making it suitable for both small-scale and large-scale wood processing operations.

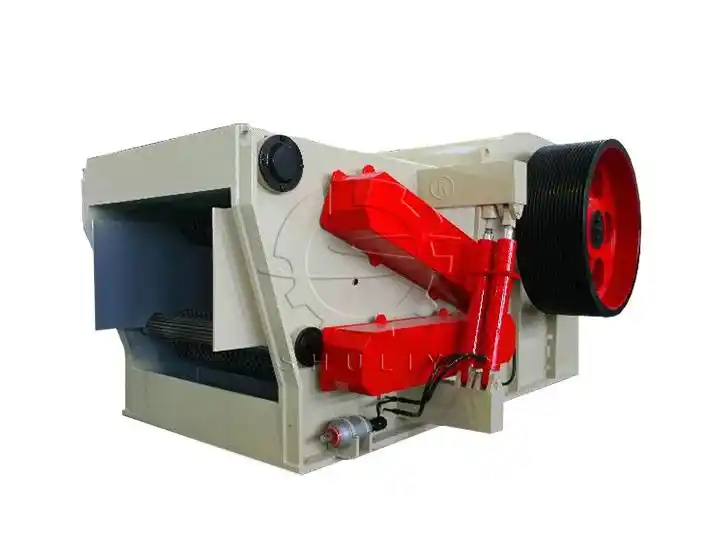

SL-216 Vertical Wood Debarking Machine Features

- High debarking capacity: Feeding port size 230×500 mm, can handle logs up to 230 mm in diameter, output up to 10 t/h.

- Durable blades: Equipped with 2 alloy steel blades, sharp and wear-resistant. Adjustable gap ensures high efficiency for different log sizes.

- Powerful drive system: Main motor 55 kW for stable cutting power; conveyor motor 3 kW for smooth feeding; hydraulic pump motor 1.5 kW for stable roller pressure.

- Uniform chip size: Debarked wood chips are about 25 mm, ideal for crushing or pulping.

- Sturdy structure: Machine weight 4070 kg, made of thick steel plates, strong and impact-resistant.

- Easy operation & maintenance: Vertical design, footprint only 1800×1900×1210 mm, saving space.

- Wide application: Suitable for panel factories, wood processing plants, biomass fuel plants, and paper mills. Can handle eucalyptus, pine, poplar, rubber wood, and more.

Technical Data of Drum Style Wood Chipper

| Model No. | SL-216 |

| Feeder port size(mm) | 230*500 |

| Blade quantity | 2 |

| Rotary | 590 |

| Max wood diameter(mm) | 230 |

| Chip size(mm) | 25 |

| Capacity(t) | 10-15 |

| Main motor power(kw) | 55 |

| Feeder motor power(kw) | 3-4 |

| Pump motor power(kw) | 1.5*1 |

| Weight(kg) | 4070 |

| Size (mm) | 1800*1900*1210 |

| Conveyor motor power(kw) | 3 |

The above is our standard model. For more model information, please contact the staff in the pop-up window on the right.

Advantages of Shuliy Drum Style Wood Chipper

Shuliy drum style wood chippers offer several advantages that make them stand out in the market:

- High Efficiency: The continuous feeding and cutting process ensures a smooth and efficient wood chipping operation, maximizing productivity.

- Uniform Output: The evenly sized wood chips or sawdust produced by the machine are ideal for various applications, including biomass fuel, animal bedding, and wood composite materials.

- Sturdy Construction: Shuliy drum style wood chippers are built with durable materials, ensuring long-lasting performance even under heavy workloads.

- Easy Maintenance: The design of the machine facilitates easy access to critical components, making maintenance and cleaning hassle-free.

- Safety Features: Shuliy drum wood chippers are equipped with safety mechanisms to prevent accidents and ensure operator protection during operation.

Working Principle of Drum Wood Chipper

The wood is fed into the feed chute and comes into contact with a high-speed rotating drum equipped with blades. As the drum rotates, the blades work together with fixed counter blades to cut the wood into uniform chips. The processed wood chips are then discharged through the outlet chute or conveyor, allowing for continuous operation.

- Material Feeding: The wood material enters the machine body through the feed inlet.

- Drum Cutting: The core component is the rotating drum (Drum), which is equipped with multiple high-speed, sharp blades on its surface.

- Power System: The drum is driven to rotate at high speed by an electric motor or diesel engine.

- Auxiliary System: Systems such as the feeding rollers and electrical control system ensure that the raw material continuously and steadily enters the cutting zone.

- Safety and Protection: Drum wood chippers are usually equipped with anti-jamming devices, emergency stop buttons, and safety guards to ensure safe operation.

Difference between Drum Wood Chipper And Disc Chipper

Drum style wood chippers and disc chippers are two common types of wood chipping machines, each with its distinct features. The main difference lies in their cutting mechanisms:

- Drum Wood Chipper: Uses a rotating drum with blades or knives to cut the wood material.

- Disc Chipper: Employs a circular disc with blades to chip the wood as it enters through the feed chute.

Drum wood chippers are generally preferred for processing larger wood materials and offer higher production capacities, while disc chippers are suitable for smaller wood pieces and provide a more precise chipping action.

How to Choose Between Drum and Disc Wood Chippers

Based on Capacity

- High capacity (≥10 t/h) → Choose a drum wood chipper, suitable for continuous industrial production.

- Low capacity (≤10 t/h) → Choose a disc wood chipper, suitable for small-scale processing or home workshops.

Based on Material Type

- Logs, branches, bamboo, wood waste → Drum chipper is suitable, blades are adjustable, strong processing ability.

- Small wood pieces or board waste → Disc chipper is sufficient, simple structure, lower cost.

Based on Usage Scenario

- Industrial continuous operation (wood chip factories, biomass power plants, pulp mills) → Drum chipper is more reliable.

- Small factories, workshops, home use → Disc chipper is more economical and practical.

Other Considerations

- Space & mobility: Disc chipper is compact and portable; drum chipper is large and requires a fixed or movable base.

- Budget: Drum chipper is more expensive but highly efficient; disc chipper is cheaper, suitable for limited investment.

How to Find the Right Drum Wood Chipper?

Selecting the right drum style wood chipper requires careful consideration of several factors, including the intended application, the volume of wood waste to be processed, and the available power source.

It is essential to assess the machine’s input capacity, cutting efficiency, maintenance requirements, and safety features. Additionally, evaluating the reputation and reliability of the manufacturer, such as Shuliy, can ensure a high-quality and durable machine that meets your specific needs.

1. Assess Your Wood Processing Needs

You need to determine the volume of wood waste they need to process daily or weekly. Understanding the quantity of wood material will help narrow down the suitable size and capacity of the drum wood chipper.

2. Consider the Type of Wood:

Different types of wood have varying hardness and moisture content. Readers should choose a drum wood chipper that can effectively handle the specific type of wood they work with, whether it’s softwood or hardwood.

3. Evaluate the Power Source

Depending on the availability of electricity or fuel, readers can choose between electric-powered or diesel-powered drum wood chippers. Electric-powered machines are suitable for indoor use, while diesel-powered ones offer more flexibility for outdoor or remote locations.

4. Check the Output Size

The desired size of wood chips or sawdust is crucial for various applications. Readers should select a drum wood chipper that can produce the desired output size, whether it’s for animal bedding, biomass fuel, or wood composite materials.

5. Examine Safety Features

Safety is paramount in any wood chipping operation. Readers should look for drum wood chippers equipped with safety mechanisms such as emergency stop buttons, safety guards, and overload protection to ensure the safety of operators.

6. Consider Maintenance and Support

Look for a drum wood chipper with easily accessible components for maintenance and repairs.

7. Choose a Reputable Manufacturer

Opt for a reputable and experienced manufacturer like Shuliy, known for producing high-quality and durable drum wood chippers. A reliable manufacturer will offer a wide range of models to cater to various needs and provide comprehensive support throughout the buying process.

Contact us

Our Wood Chipper is manufactured using advanced technology and high-quality materials, ensuring efficient and reliable wood processing, thus enhancing productivity.

In addition to the Wood Chipper, we also offer wood crushers, wood shavers, and wood debarkers, providing comprehensive solutions to meet your various processing requirements.

Our team of professional business managers is always available to provide personalized consultation services, helping you choose the most suitable equipment to maximize your production efficiency. Contact us now to learn more!

FAQs of Drum Wood Chipper for Sale

Q: What is the price of wood drum chipper?

A: Generally, the price for a small to mid-sized wood drum chipper can range from $2,000 to $10,000. Larger and more advanced models may cost anywhere from $15,000 to $30,000 or more.

It’s important to consider the specific requirements and features needed to find the most suitable option within the given price range.

Q: What is better drum or disc on wood chipper?

A: Drum wood chippers are considered better than disc chippers for several reasons. They possess superior rotational energy, allowing them to cut a wider range of materials effectively.

Moreover, their compact design makes them easy to maneuver and transport. Additionally, drum wood chippers can be engineered to be exceptionally strong, ensuring durability and reliability in heavy-duty wood processing tasks.

Q: How fast does a chipper drum spin?

A: A chipper drum typically spins at a speed ranging between 1,000 and 2,000 revolutions per minute (rpm). This high-speed rotation enables efficient and rapid chipping of wood and other materials.

Q: What are the different types of chippers?

A: There are two main types of chippers: those powered by internal combustion engines (gas or diesel) and those powered by electricity.

Gas or diesel-powered chippers are ideal for remote or outdoor locations where electricity may not be readily available, while electric chippers are more suitable for indoor or urban environments due to their quieter operation and lower emissions.

Hot Product

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

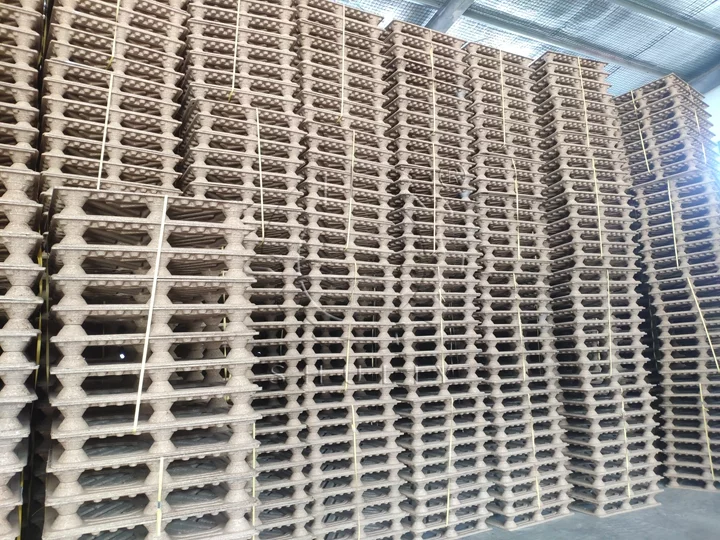

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…