Wood Pallet Block Making Machine

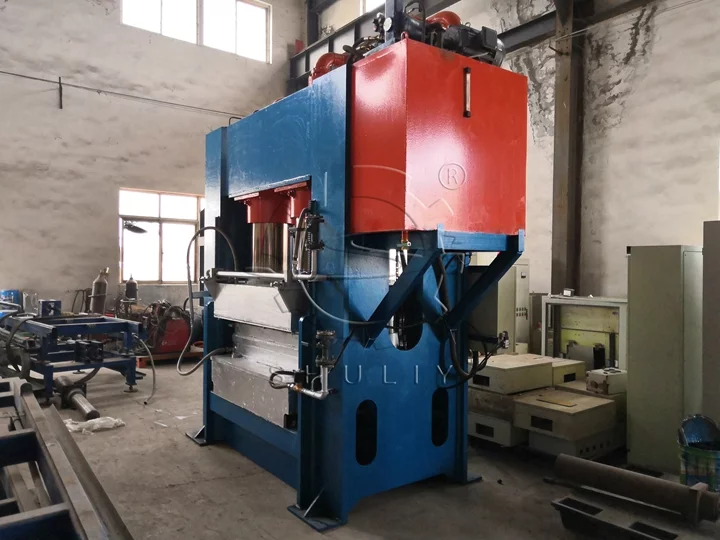

Pallet block press machine

Wood Pallet Block Making Machine

Pallet block press machine

Features at a Glance

The wood pallet block making machine, also known as a sawdust block machine or wood block forming machine. The wood pallet block making machine uses high pressure and high temperature to turn wood chips, sawdust, and other wood waste into special pallet blocks.

These compressed blocks are then used as raw materials for the production of sturdy and durable pallets, which are widely utilized in various industries such as logistics, warehousing, transportation, and material handling.

Shuliy offers 5 models of wood pallet block machines, with a daily output of 3.5–5 cubic meters. The produced wood blocks have a smooth surface and are strong and durable.

This innovative technology offers numerous advantages, ensuring versatility and promising prospects for your investment. If you’re interested in pricing details, please don’t hesitate to reach out to us at your earliest convenience. We’re here to assist you!

Raw Material Used for Wood Block Machine

The raw materials used for the wood pallet block making machine include various wood waste materials, such as sawdust, wood shavings, wood chips, and other biomass residues.

With the utilization of such renewable materials, the wood pallet block making machine contributes to waste reduction, cost-effectiveness, and environmental conservation in the manufacturing process.

Advantages of the Produced Blocks

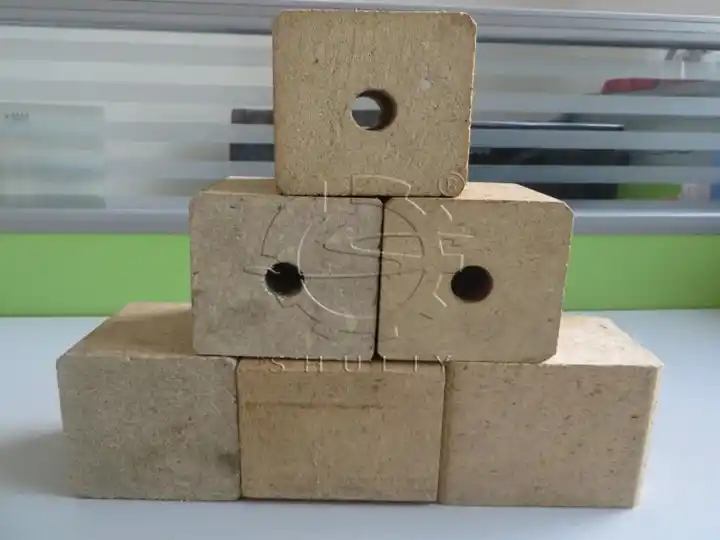

- Smooth and flat surface: The blocks have a clean, smooth surface, providing a good touch and making pallet assembly and handling easier.

- Excellent water resistance: They do not crack after 48 hours of soaking and remain intact under sun and wind, with strong weather resistance.

- Strong screw-holding and load capacity: Vertical screw-holding force is 1590 N, horizontal 1660 N, ensuring stable and reliable pallet assembly.

- Eco-friendly and safe: Export-ready without fumigation, formaldehyde emission meets E2 standards, non-toxic and environmentally friendly.

- High internal bonding strength: Internal bonding strength reaches 1.07 MPa, with high density and durability.

What is the Working Principle of the Wood Pallet Block Machine?

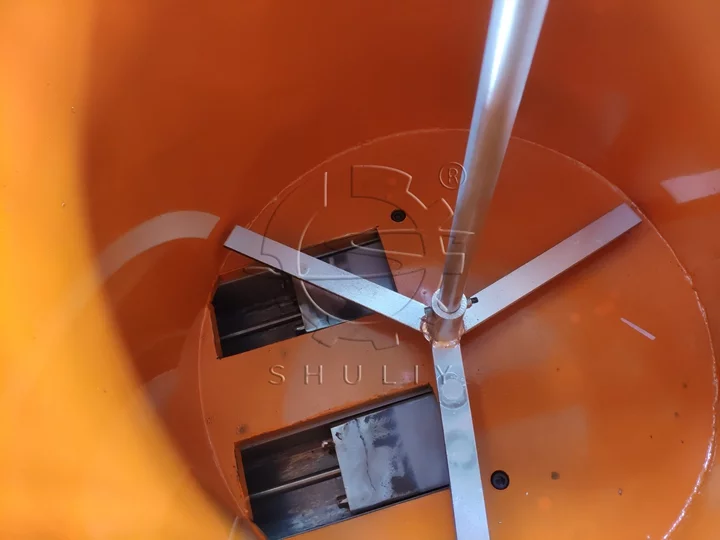

The working principle of the wood pallet block machine is to use high temperature and high pressure to compress wood waste, such as sawdust and wood shavings, into dense blocks. After drying, the raw material is fed into a heated mold cavity. At about 150–200°C, the lignin in the wood softens and acts as a natural adhesive.

Then, the hydraulic system applies high pressure, tightly binding the wood particles to form high-density blocks. The formed blocks are cooled and solidified, with a smooth surface and high strength, making them ideal for producing pallet feet or legs.

Innovative Structure and Operation of the Wood Pallet Block Making Machine

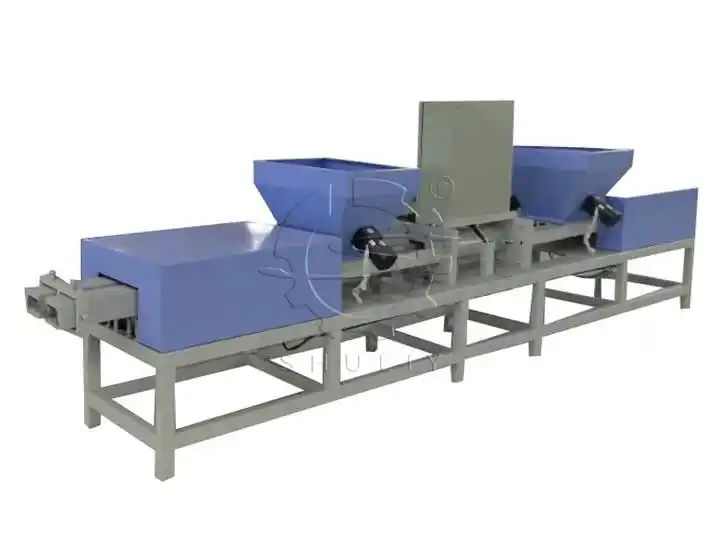

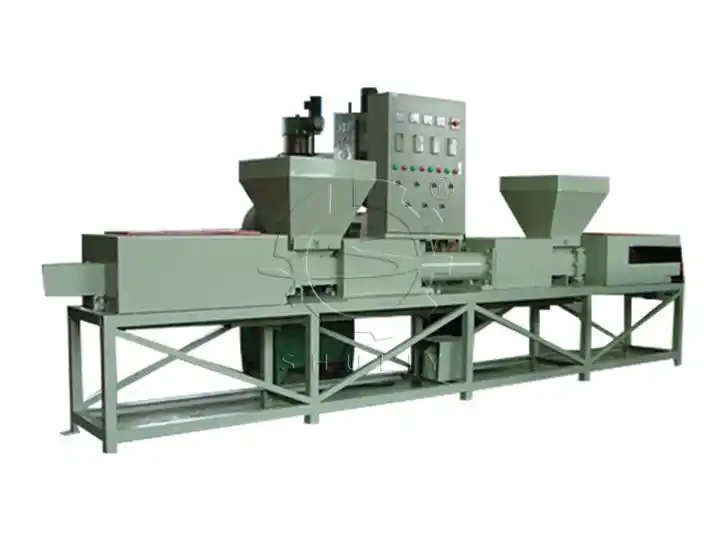

The wood pallet block making machine is equipped with a set of symmetrical extrusion devices on both the left and right sides, forming the core of its operational mechanism.

Its main structure comprises essential components such as the feeding port, frame, heating plate, hydraulic cylinder, and extrusion die, ensuring seamless functionality.

Efficient Operation

During operation, the internal hydraulic system feeds sawdust into the machine through the inlet, moving it forward inside the equipment. When the sawdust enters the heating zone, the lignin begins to thermally decompose and bonds with molecules in the material, forming strong chemical bonds. This tightly binds the wood particles, completing the formation of high-density blocks.

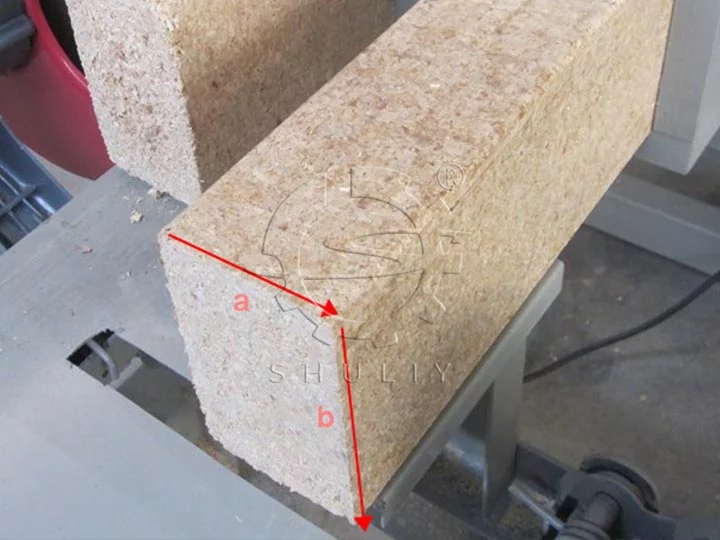

Superior Quality Output

The wood pallet block making machine produces sawdust blocks with a smooth surface, high density, and exceptional hardness. Their robust structure ensures excellent wear resistance and outstanding load-bearing capacity, delivering reliable, long-lasting performance across a wide range of applications. The discharge outlet can be customized to different sizes according to customer requirements.

Wood Pallet Block Making Machine Specification

Technical Specifications

| Model | Power | Capacity | Density | Dimension | Weight |

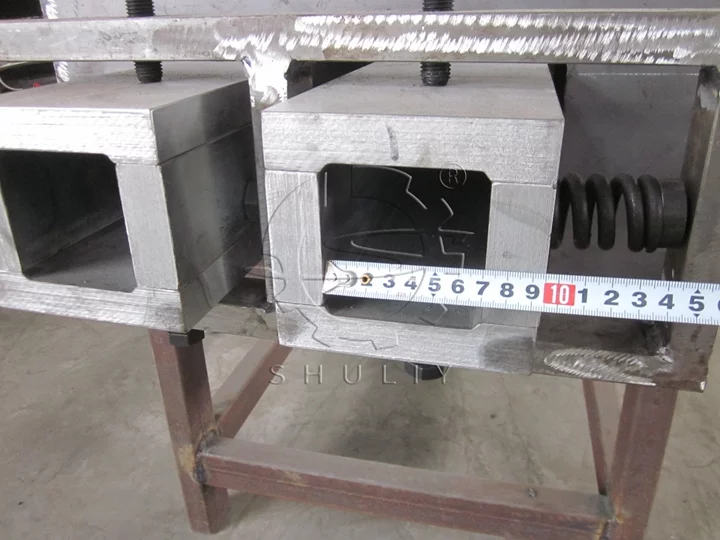

| SL-75/2 | 15KW | 3.5m³/d | 550–700 kg/m³ | 75*75*1200mm | 1500kg |

| SL-90/2 | 15KW | 4m³/d | 550–700 kg/m³ | 90*90*1200mm | 1800kg |

| SL-100/2 | 18KW | 5m³/d | 550–700 kg/m³ | 100*100*1200mm | 2000kg |

| SL-120 | 15KW | 3.5m³/d | 550–700 kg/m³ | 100*120*1200mm | 1500kg |

| SL-145 | 18KW | 3.5m³/d | 550–700 kg/m³ | 145*145*1200mm | 1800kg |

Notes

- The hydraulic system pressure must not exceed 10 MPa.

- The hydraulic system flow must not exceed 7.3 L/min.

- The cylinder pressure is 4 MPa.

If you have more questions or want to know which machine suits you best, feel free to contact us on the right. We will get back to you within 24 hours.

What can be customized on a wood block machine?

- Block size: Length, width, and height can be adjusted to meet different pallet or leg specifications.

- Block density and pressure: The hydraulic system pressure can be adjusted to control block firmness and hardness, suitable for different load requirements.

- Outlet design: The outlet size can be customized for easy connection with production lines or packaging equipment.

- Mold type: Single or multi-mold designs are available to produce single or multiple blocks at a time.

- Automation level: Options include semi-automatic or fully automatic, covering feeding, pressing, and block ejection.

- Material adaptability: Heating and pressing parameters can be optimized for different biomass materials such as sawdust, wood shavings, or wood chips.

- Material and durability: The machine body and molds can be made of carbon steel or stainless steel, depending on production environment and lifespan requirements.

- Color: The exterior color can be customized to match factory style or brand image.

Application of the Wood Pallet Block

The wood pallet blocks produced by the wood pallet block making machine have versatile applications across various industries. These durable and uniform blocks are commonly used for pallet production, effectively replacing traditional wooden pallets.

The wood pallet blocks offer exceptional strength, stability, and resistance to decay, making them ideal for heavy-duty loads and long-term storage. Moreover, these blocks are also utilized in the construction industry as a sustainable alternative to conventional building materials.

Additionally, it finds application in logistics, warehousing, and transportation sectors due to its superior load-bearing capacity and easy handling features. The wood pallet blocks not only reduce material waste but also promote eco-friendly practices, making it a preferred choice for industries seeking sustainable and cost-effective solutions.

Sawdust Pallet Block Making Machine Advantages

- Efficient Resource Utilization: Our machine maximizes the utilization of sawdust and other wood waste materials, effectively converting them into high-quality pallet blocks. This ensures minimal waste and optimal resource utilization, contributing to cost savings and sustainability.

- Cost-Effective Solution: By utilizing sawdust and wood waste as raw materials, our machine provides a cost-effective solution for pallet production. It helps reduce the need to purchase new materials, thereby lowering production costs and improving profitability.

- Environmentally Conscious Operation: Our machine promotes environmental sustainability by minimizing waste generation and reducing reliance on new timber resources. It contributes to eco-friendly practices by repurposing wood waste into valuable pallet blocks, thereby reducing environmental impact.

- Consistent Quality Output: Our machine ensures consistent quality output with smooth surfaces, high density, and reliable load-bearing capacity in the produced pallet blocks. This consistency meets industry standards and enhances the reliability of pallets for various applications.

- Streamlined Production Process: With automated operation and efficient workflow, our machine streamlines the pallet block production process, reducing manual labor and increasing production efficiency. This results in higher productivity and faster turnaround times for our customers.

- Versatile Applications: The pallet blocks produced by our machine find versatile applications across industries such as logistics, warehousing, and transportation. They are suitable for various packaging solutions, including pallets, crates, and more, facilitating efficient material handling and storage practices.

Feel free to contact us!

With impeccable craftsmanship and reliable performance, our Wood Pallet Block Making Machine delivers exceptional quality and efficiency to your production processes. Whether for logistics, transportation, or warehousing, our product meets your needs and adds value to your business.

Feel free to contact us for more information about our Wood Pallet Block Making Machine. We look forward to partnering with you to create a brighter future together.

If you want to turn logs into sawdust, we offer wood chippers, wood crushers, and drum dryers. For detailed plans, please refer to our wood sawdust block production line solutions.

Wood Comprehensive Crusher | Wood Pallet Shredder

The wood comprehensive crusher, commonly known as a wood pallet…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process various wood…

Wood Hammer Mill | Hammer Mill Shredder

The wood hammer mill adopts a hammer and screen system…

Wood Shavings Machine | Log Shavings for Animal Bedding

The wood shaving machine can efficiently cut logs, branches, and…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chippers are designed to handle a wide range…

Wood Debarking Machine | Log Peeling Machine

Wood debarking machine, also known as a log peeling machine,…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for sale. You…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Wood Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a…

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Rice Husk Drying Machine | Rotary Dryer for Sale

Our rice husk drying machine, or a rotary…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…