Wood Sawdust Briquettes Production Line for Pini Kay

Pini kay heat logs plant | sawdust briquettes processing line

Wood Sawdust Briquettes Production Line for Pini Kay

Pini kay heat logs plant | sawdust briquettes processing line

Features at a Glance

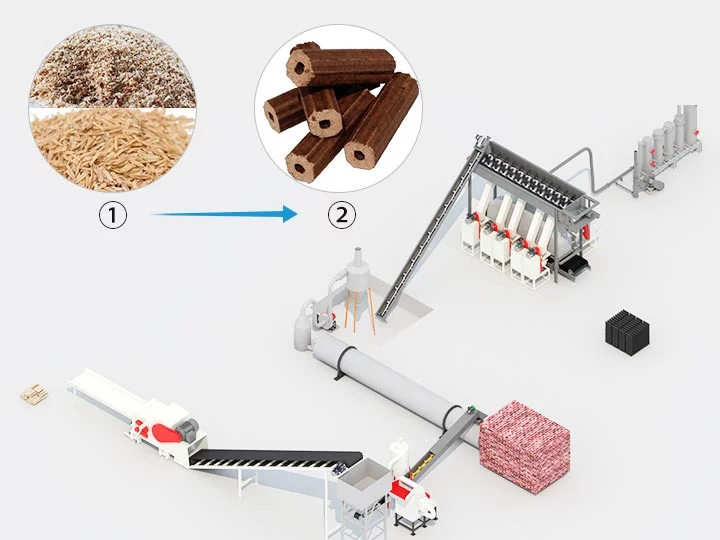

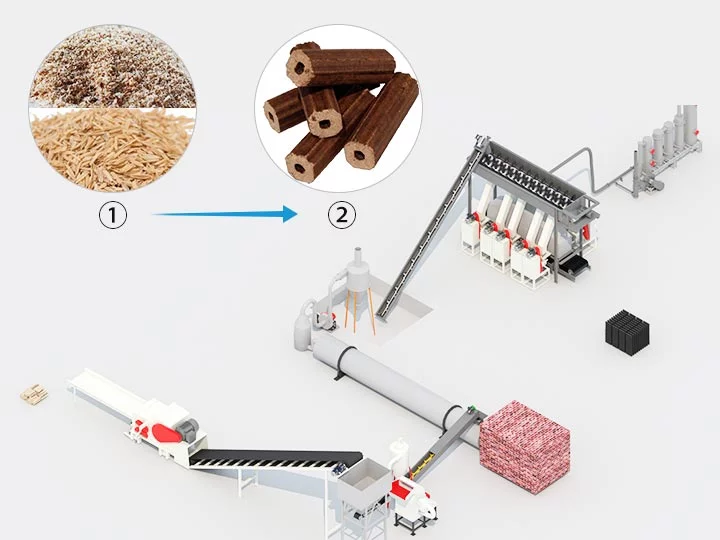

This wood sawdust briquettes production line, also known as the pini kay processing plant, is used to convert sawdust and other raw materials into biomass fuel known as pini kay heat logs. The main equipment of this production line includes a wood chipper, wood crusher, rotary sawdust dryer, sawdust briquette machine, and screw conveyors.You can efficiently produce high-quality pini kay briquettes that are eco-friendly and widely used for heating and cooking purposes. Contact us for the promotional price.

The capacity of this wood sawdust briquette production line is mainly determined by the number of sawdust briquette machines. Each briquette machine has a production capacity of 250 kg/h. The most common configuration of this line is 1 ton per hour.

Regardless of the required output, Shuliy can customise and configure the production line according to your needs. Welcome to contact us through the online chat window on the right for more details.

Application of Wood Sawdust Briquettes Production Line

The application of the wood sawdust briquettes production line is vital in the production of high-quality biomass fuel known as pini kay heat logs. This industrial production line efficiently processes sawdust or rice husks by extruding them at high temperatures and pressures.

Pini kay heat logs produced through this process have numerous applications across various industries and sectors. They serve as an eco-friendly and sustainable alternative to conventional fuels like coal and charcoal. These briquettes are widely used for heating, cooking, and power generation purposes. Residential households, commercial establishments, and industrial facilities can benefit from the clean and efficient energy source provided by pini kay processing plant.

Raw Material for Producing Wood Sawdust Briquettes

In addition to common raw materials such as logs, hardwood, and tree branches (e.g., pine and oak), the briquette production line can process a wide range of biomass materials.

Wood-Based Materials

- Logs and hardwood

- Tree branches and wood offcuts

- Sawdust and wood shavings

Agricultural Residues

- Cotton stalks

- Sorghum stalks

- Rice straw

- Corn stalks

Crop Processing By-products

- Corn cobs

- Rice husks

Nut and Palm Waste

- Peanut shells

- Palm shells

- Other agricultural processing residues

Wood Sawdust Briquettes Production Process

This biomass briquette production line mainly includes a wood chipper, wood crusher, sawdust dryer, and biomass briquette machine. Through processes such as chipping, crushing, drying, and briquetting, the raw materials are processed into high-density biomass fuel—biomass sawdust briquettes.

- Function: Efficiently converts large logs or branches into uniform wood chips or sawdust.

- Core Component: Rotating drum with cutting blades for precise wood cutting.

- Capacity: 10–15 tons per hour, ideal for large-scale production.

- Applications: Forestry, woodworking, and biomass processing.

- Advantages: High efficiency, consistent output, and wide applicability.

- Difference from Disc Chippers: Drum style is better suited for high-volume, continuous production.

- Function: Crushes raw materials—logs, hardwoods, branches, and agricultural straws—into smaller particles for easier handling and processing.

- Purpose: Prepares sawdust for smooth and efficient production of high-quality briquettes.

- Adjustable Fineness: Equipped with interchangeable screens of different hole sizes to produce sawdust with varying particle sizes.

- Typical Use: Sawdust for pini kay briquettes is usually around 5mm in size.

Sawdust Dryer

- Function: Reduces the moisture content of sawdust to an optimal level for smooth and efficient briquette production.

- Type: Drum dryer, commonly used for powders and granular materials.

- Moisture Control: Adjusts sawdust moisture to below 12% to ensure high-quality briquettes.

Sawdust Briquette Making Machine

- Function: Converts sawdust, wood shavings, and straw into high-density fuel briquettes.

- Capacity: 160–320 kg/h, suitable for small to large-scale production.

- Technology: Twin-screw extrusion with intelligent temperature control, achieving a compression ratio over 8:1.

- Calorific Value: 4000–4500 kcal/kg, maximising biomass energy utilisation.

- Versatility: Modular mold system supports 6–80mm square and round briquettes.

- Applications: Boilers, power generation, and household fuel, promoting an eco-friendly circular economy.

Advantages of Sawdust Briquettes Production Line

- Supports Multiple Raw Materials: Processes sawdust, wood shavings, branches, straw, and other agricultural or forestry residues for efficient waste utilization.

- High Capacity & Stability: Production depends on the number of briquette machines, with each machine producing around 250 kg/h. The most common production line output is 1 t/h. Shuliy can configure the line for any scale, ensuring continuous and efficient operation.

- High-Quality Fuel: Briquettes are dense with low moisture content, offering high combustion efficiency and a calorific value of 4000–4500 kcal/kg, suitable for boilers, power generation, and household heating.

- Versatile Sizes: Modular mold system supports 6–80 mm square and round briquettes to meet different customer requirements.

- Eco-Friendly & Cost-Effective: Reduces biomass waste, promotes green production and circular economy, with low cost and quick return on investment.

- Flexible Support: Whether starting a new plant or expanding an existing line, Shuliy provides complete solutions and promotional offers.

Finished Product Display

Our wood sawdust/biomass briquettes are uniform, high-density, and low in moisture, with a calorific value of 4000–4500 kcal/kg. Available in 6–80 mm square or round shapes, they are ideal for boilers, power generation, and household heating, offering an eco-friendly and efficient energy solution.

1000kg/h Sawdust Briquette Making Machine Line – Main Equipment List

| Equipment Name | Main Specifications(mm) | Power |

|---|---|---|

| Wood Sawdust Machine | Capacity: 1000 kg/h; Dust remover diameter: 1000mm ; 6 dust bags | 45 kW (main motor) + 7.5 kW (fan) |

| Screw Conveyor | Diameter: 219mm; U-type; Length: 6 m | 4 kW |

| Rotary Dryer Machine | Capacity: 1000 kg/h; Drum diameter: 1000 mm; Thickness: 10 mm; Weight: 2800 kg | 3 kW (main motor) + 15 kW (fan) |

| Screw Conveyor | Diameter: 273 mm; U-type; Length: 4 m | 4 kW |

| Screw Feeder | Evenly distributes material to 4 briquette machines, with a protective cover | 5.5 kW |

| Sawdust Briquette Machine | Capacity: 200–250 kg/h per set; Dimension: 1770 × 700 × 1450 mm; Weight: 550 kg per set | 18.5 kW per set |

| Smoke Collector | Including fan and purification system | 4 kW |

| Belt Conveyor | For collecting and conveying finished briquettes; With control cabinet | 1.5 kW |

Overall Technical Parameters

| Item | Specification |

|---|---|

| Designed Capacity | 1 ton/hour |

| Total Briquette Output | 800–1000 kg/h |

| Total Installed Power | 163.5 kW |

| Required Working Area | 200–300 m² |

| Required Labor | 3–4 workers |

Key Configuration Details

| Equipment | Key Configuration |

|---|---|

| Wood Sawdust Machine | Screen size optional: 0.6–12 mm; Equipped with air-lock and control cabinet; Wearing parts: hammers and screen |

| Rotary Dryer | Equipped with 1 m cyclone separator; Standard magnetic coil; Adjustable-speed motor; Independent control cabinet |

| Briquette Machine | Mold material: chromium-manganese alloy; C-type belt; National standard copper motor; Reinforced bearing; U-steel frame structure |

Related Product – Charcoal Machine Production Line

The charcoal machine production line is designed to convert biomass materials such as wood, bamboo, and straw into high-quality charcoal. The line integrates crushing, drying, carbonization, and shaping into a fully automated and efficient process. The finished charcoal is dense, long-burning, and has a stable calorific value, making it ideal for industrial fuel, household heating, and barbecue use.

This production line can be seen as an extension of the wood sawdust briquettes production line: by adding a carbonization furnace to the briquette line, sawdust and other biomass pellets can be directly transformed into high-quality charcoal, maximising biomass utilisation and providing a complete green energy solution.

Hot Product

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality…

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Shisha Charcoal Packing Machine

Our shisha charcoal packing machine is an important…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…