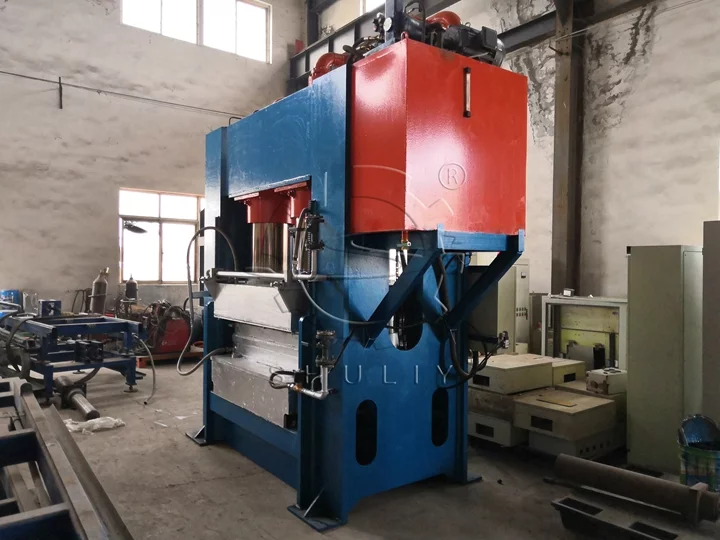

Wood shaver machine shipped to UAE

Our wood shaver machine recently became an integral part of a client’s operations in the United Arab Emirates.

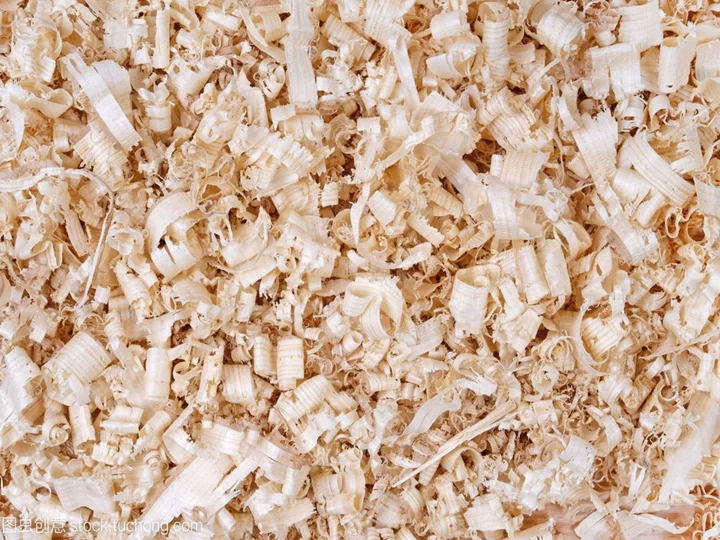

Ensuring high-quality shavings for animal bedding

The client, a leading supplier of animal bedding, faced difficulties meeting the growing demand for premium wood shavings. Their previous equipment was limited in efficiency and versatility, which hindered their ability to deliver consistent quality. The primary challenges included:

- The need for a machine that could process a variety of raw materials.

- The demand for clean, refined wood shavings suitable for high-end applications.

- The necessity to improve production speed and efficiency.

Upgrading with the wood shaver machine

Our wood shaver machine provided a comprehensive solution, combining versatility, precision, and efficiency to meet the client’s specific needs.

Versatile raw material handling

The machine processes multiple types of wood, including logs, branches, solid wood boards, and peeled wood. The use of peeled wood, in particular, ensures cleaner and more refined shavings for premium applications.

Advanced working mechanism

- Feeding and cutting. Raw materials are fed through the port, where high-speed blades initiate the shaving process.

- Crushing and refining. The shavings are further refined by the rotating hammer within the crushing chamber.

- Customizable output. Adjustable blade lengths allow for shavings of various dimensions and thicknesses, catering to diverse applications.

- Discharge system. The integrated fan blades propel the processed shavings through the discharge port efficiently.

Implementation and integration

- Needs assessment. We collaborated closely with the client to understand their production goals and challenges.

- Installation and training. The machine was installed seamlessly, with comprehensive training provided to ensure optimal operation.

- Operational support. Continued technical support was made available to maximize the machine’s efficiency.

Results and impact

Increased efficiency

The wood shaver machine reduced production time by 35%, allowing the client to process larger quantities of material with minimal effort.

Superior shaving quality

The ability to produce cleaner, more uniform shavings enhanced the client’s product reputation in the market.

Versatile applications

The machine’s adaptability enabled the client to diversify their product offerings, expanding into packaging and other high-value markets beyond animal bedding.

Conclusion

The wood shaver machine proved to be a game-changer for our client in the UAE, addressing their challenges and elevating their production capabilities. By delivering high-quality, customizable shavings efficiently, the machine enabled the client to meet market demands and expand their business.

Looking to upgrade your operations with a wood shaver machine? Contact us today for expert guidance and superior equipment tailored to your needs.