Charcoal Briquette Machine | Charcoal Extruder Machine

Charcoal Briquette Machine | Charcoal Extruder Machine

Features at a Glance

The charcoal briquette machine, also known as the charcoal extruder machine, mainly uses a screw extrusion structure to compress charcoal powder or coal powder into uniform briquettes or coal rods.

This charcoal briquette extruder is widely used in the production of machine-made charcoal, BBQ charcoal, heating fuel, and industrial energy applications.

It enables users to recycle and reuse fine charcoal powder, coal powder, and crushed carbon materials by compressing them into solid fuel rods, making it an efficient and practical energy storage and utilization device.

With a production capacity of 500–1000 kg/h, it is especially suitable for small to medium-sized charcoal processing plants.

Working Principle of Charcoal Briquette Machine

The briquette machine adopts screw extrusion technology to compress the mixed charcoal or coal powder into rod-shaped products under high pressure. The entire process is environmentally friendly, requiring no chemical binders—only water or a small amount of natural adhesive is needed.

What is the Working Process of the Charcoal Extruder Machine?

Raw Material Preparation

Charcoal or coal powder is mixed with water and a small amount of binder to achieve proper moisture and consistency, usually using a mixer.

Feeding

The mixed material is fed into the extruder through the feeding hopper.

Screw Extrusion

A screw shaft inside the machine rotates at high speed to compress and push the material forward.

Mold Shaping

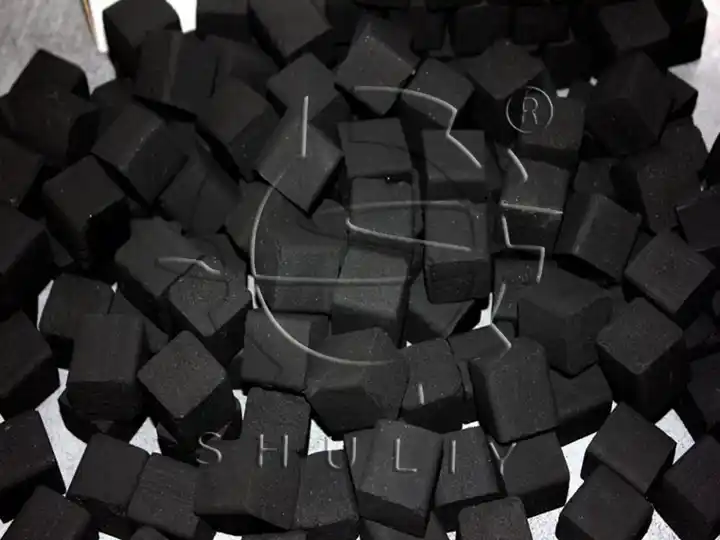

Under high pressure, the material is extruded through the mold to form uniform briquettes—round, hexagonal, hollow, or solid.

Briquette Output

The finished briquettes are discharged automatically and sent for cooling, drying, or packaging.

Raw Materials of Charcoal Briquette Extruder Machine

The raw materials used by the charcoal briquette extruder machine typically include charcoal powder, coal powder, biomass materials (such as sawdust, rice husks, and agricultural waste), binder (such as starch or clay), water, and additives (such as curing agents).

These materials are processed and compressed by the charcoal briquette extruder machine to produce high-quality charcoal briquettes, which are used for various purposes, including cooking, heating, and industrial applications.

Applications of the Charcoal Briquette Machine

- Round briquettes — Household heating, industrial boiler fuel, agricultural drying, BBQ charcoal

- Hexagonal briquettes — High-efficiency BBQ charcoal, catering industry grilling, hot pot charcoal

- Hollow briquettes — Commercial BBQ charcoal, high-efficiency industrial combustion, eco-friendly energy-saving charcoal

- Square or block briquettes — Long-duration industrial boiler fuel, heating stoves, and large-scale drying equipment fuel

Advantages of charcoal extruder machine

High Productivity and Efficiency

Output reaches 500–1000 kg per hour, suitable for continuous operation in small to medium-sized charcoal plants.

Robust Structure

The machine body is made of thickened steel, wear-resistant, and has a long service life.

High Forming Rate

The briquettes are dense and not easy to break, with a long burning time and high calorific value.

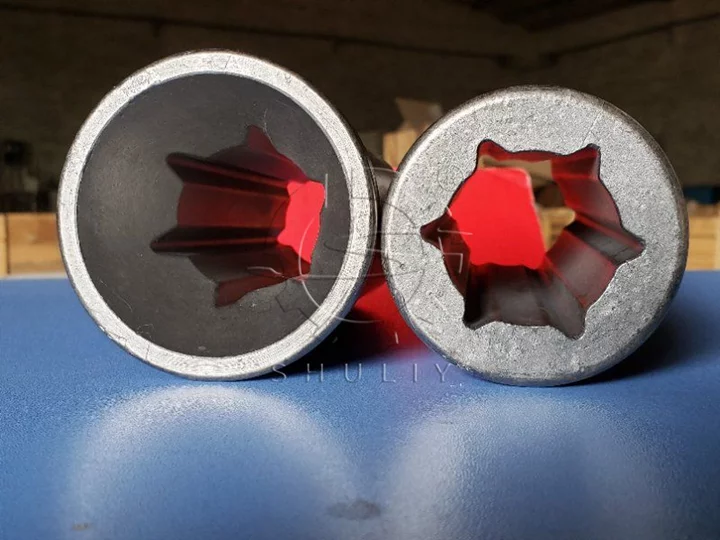

Interchangeable Molds

Molds can be replaced to adjust the shape and size of the briquettes, offering great flexibility.

Easy Operation

Can be combined with mixers, conveyors, and other equipment to achieve semi-automatic production.

Energy Saving and Environmentally Friendly

Fully mechanical compression without the need for chemical binders, making it green and eco-friendly.

Parameters of Charcoal Briquette Making Machine for Sale

Shuliy offers a variety of charcoal briquette machine models. Welcome to contact us for more information.

| Model | Capacity | Power | Dimension | Weight |

| SL-CB160 | 500kg/h | 11kw | 2050*900*1250mm | 900kg |

| SL-CB180 | 1000kg/h | 22kw | 2250*1400*600mm | 1300kg |

Different Cutting Methods in Charcoal Extruder Machine

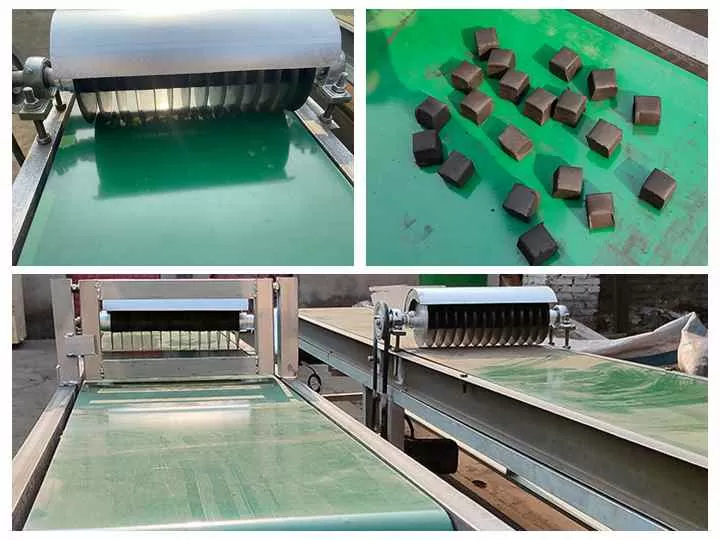

It offers various cutting methods to shape and size the briquettes.

These methods, including pneumatic cutting, cubic cutting, and intelligent cutting, provide flexibility and precision in producing charcoal briquettes of different shapes and sizes. You can choose the best one for your project.

Let’s explore these cutting methods in more detail:

Pneumatic Cutting

Pneumatic cutting is a commonly used method. It involves the use of a pneumatic cutting machine installed at the exit of the charcoal extruder machine, equipped with an induction device.

Cubic Cutting

The coal rods pass through this machine, where they undergo precise cutting to achieve a uniform shape and size. This cutting method is ideal for producing charcoal briquettes with a cubical form, which may be preferred for certain applications or market demands.

Intelligent Cutting

This cutting method incorporates an intelligent control system, allowing for the adjustment of cutting lengths according to specific requirements. It offers the flexibility to cut coal rods into various shapes, accommodating different market preferences and customized briquette designs.

The intelligent control system ensures precise and accurate cutting, enhancing the overall quality of the charcoal briquettes produced.

Mold Display

How to Use Charcoal Briquette Machine?

- Before starting each shift, check whether the rotating parts are flexible and whether there is any abnormal noise, and the machine can be fed into production after 2 to 3 minutes of empty operation.

- The raw materials must be processed, the maximum particle size is less than 3mm, add water, add binder, curing agent, stir, and retting for 24 hours before use.

- If the feeding port is blocked, use wooden or bamboo strips to clear it, and do not use metal rods.

- The bearings of the rotating parts of the machine should be injected with lubricating oil regularly, and the temperature of the bearing parts should not exceed 60 °C.

- Stop unloading before stopping the machine, stop the machine after the material in the cylinder is squeezed out, disassemble the machine head, clean it, and reinstall it, so that it can be used after getting off work.

- To prevent the motor from overloading, it is recommended that the user install a current and voltage meter, and adjust the feeding amount and water content according to the current and voltage meter.

What About the Charcoal Briquette Machine Price?

When considering purchasing a charcoal briquette machine, one important factor to consider is the price. By considering the price in conjunction with the machine’s quality and performance, you can make a wise investment in it that delivers optimal results.

With factory prices, you can get a more competitive price than other suppliers. Shuliy stands out as a reputable provider of high-quality and competitively priced features.

With their diverse machine options, customization capabilities, excellent customer support, and comprehensive after-sales services. Get in touch with us now to get detailed quotations.

Conclusion

As a leading supplier of charcoal briquette making machines, we are committed to providing our customers with high-quality products and comprehensive services. Our charcoal briquette making machines are designed with advanced production technology, ensuring efficiency, environmental friendliness, and energy savings, meeting the diverse production needs of our customers.

If you are interested in our charcoal briquette making machines or have any questions, please feel free to contact us. Our sales team is dedicated to providing you with detailed product information, technical consultation, and quotation services.

Additionally, we have a professional pre-sales and after-sales service team to provide you with one-stop services, including equipment installation, commissioning, operation training, maintenance, and troubleshooting, ensuring that you can use our products with ease and achieve the best results.

How to Choose the Right Charcoal Extruder Machine?

As a machine used to compress coal powder, charcoal powder,…

Hot Product

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Coal Briquette Machine | Honeycomb Coal Press Machine

Coal briquette machine can produce different shape and…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

Sawdust Briquette Making Machine | Biomass Briquette Machine

The sawdust briquette making machine is an environmentally…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…