Wood Crusher Machine | Industrial Wood Shredder Machine

Sawdust making machine

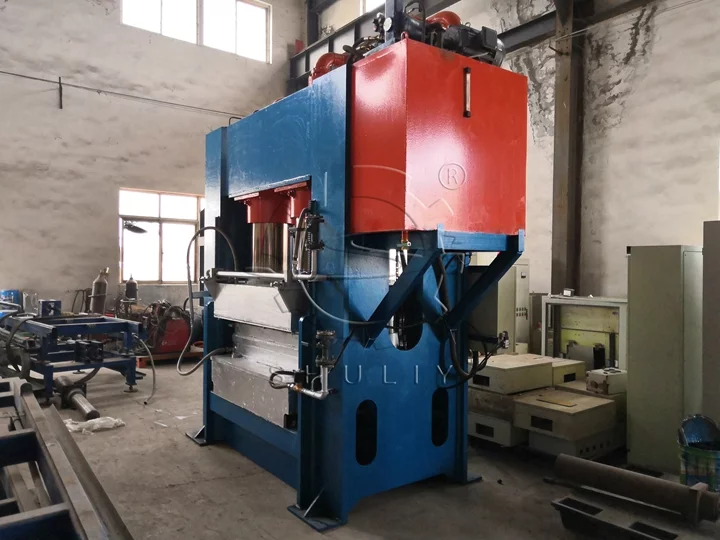

Wood Crusher Machine | Industrial Wood Shredder Machine

Sawdust making machine

Features at a Glance

Wood crusher machines are designed to efficiently process various wood wastes into sawdust of different finenesses. From logs to branches, bamboo to straws, and other biomass materials, our wood crusher swiftly transforms them into sawdust with high production efficiency.

The commercial wood crusher has a production capacity ranging from 600 ~ 4000 kg/h, and it produces uniform-sized wood chips, as small as 0.3~0.8 cm.

Also, we offer six models to choose from: SL-420, SL-500, SL-600, SL-700, SL-900, and SL-1000.

Our equipment has been successfully exported to more than 20 countries and regions, including Germany, South Africa, Brazil, the United States, Ghana, Indonesia, Vietnam, South Korea, Australia, Jordan, and Canada, and continues to achieve outstanding results worldwide.

Advantages of Electric Wood Shredder Machine

As a reputable supplier of high-quality wood crusher machines, we take pride in offering our customers a range of advantages that set our electric wood shredder machine apart from the competition.

High-Efficiency Output

With output ranging from 300 kg/h (SL-420) to 4000 kg/h (SL-1200), these machines meet the needs of both small workshops and large-scale operations. Models above SL-700 are especially ideal for bulk wood processing, significantly improving efficiency.

Powerful Performance

With power options ranging from 11 kW to 90 kW, the machines are capable of processing tough materials. For example, the SL-900 is equipped with a 55 kW motor and can easily crush wood up to 22 cm in diameter.

Flexible Feeding, Strong Adaptability

Various feed sizes are supported—for example, SL-500 accepts up to 15 cm and SL-1000 up to 26 cm—making it suitable for processing wood of different shapes and sizes with minimal pre-treatment.

Compact Structure, Easy Maintenance

The machines are designed with a compact footprint for easy installation and operation. Blade replacement and screen cleaning are simple, resulting in low maintenance costs.

Wide Application, High Economic Value

Widely used in the production of biomass pellets, charcoal, and landscaping waste recycling, the machines offer high material utilization and reduce resource waste.

Comprehensive After-Sales Service

Customer satisfaction is at the heart of our business philosophy. We offer an intimate after-sales service, ensuring that our customers receive prompt and effective support whenever needed.

Wood shredder machine working Principle

The wood crusher machine operates based on a straightforward working principle. It typically consists of a feeding hopper, a crushing chamber with rotating blades or hammers, and a discharge chute. Here is a simplified explanation of the working principle.

The raw materials are fed into the machine’s feeding hopper. Inside the machine’s crushing chamber, the rotating blades or hammers exert force on the raw materials, effectively breaking them down into smaller particles or chips. The crushing action can be achieved through mechanisms like shearing, cutting, or impact.

Structure of Wood Crusher Machine for Sale

The wood crusher machine for sale features a robust and well-designed structure that enables efficient and reliable wood processing. It consists of several key components.

- Feeding Hopper: Located at the top of the machine, the feeding hopper is where the raw materials, such as wood logs or branches, are loaded into the machine for processing.

- Conveyor Belt: It is used to transport the raw materials from the feeding hopper to the crushing chamber. The conveyor belt ensures a continuous and regulated feeding process, enhancing the overall efficiency of the machine.

- Crushing Chamber: It consists of a robust housing or frame that houses the cutting mechanism. Inside the chamber, there are rotating blades or hammers that effectively break down the wood into smaller particles or chips.

- Cutting Mechanism: It typically includes sharp blades or hammers that rotate at high speed, delivering strong impact or cutting force to the wood. The specific design and configuration of the cutting mechanism may vary depending on the machine model and intended application.

- Discharge Chute: After the wood materials are crushed, they are discharged through the machine’s discharge chute. The discharge chute provides an exit point for the processed wood particles or chips, allowing them to be collected or further processed as needed.

- Motor and Control System: The electric wood shredder machine is powered by an electric motor that drives the cutting mechanism. It is equipped with a control system that allows operators to adjust the speed, feeding rate, and other parameters to optimize the crushing process.

- Support Structure and Frame: It is designed to withstand the vibrations and forces generated during the wood crushing process.

Shuliy Wood Shredder Machine for Sale

| Model | Capacity | Electric Power | Feeding size |

| SL-420 | 300-400 kg/h | 11kw | 10cm |

| SL-500 | 500-600kg/h | 18.5kw | 15cm |

| SL-600 | 800-1000kg/h | 30kw | 17cm |

| SL-700 | 1200-1500kg/h | 37kw | 20cm |

| SL-900 | 2000-2500kg/h | 55kw | 22cm |

| SL-1000 | 3000-3500kg/h | 75kw | 26cm |

| SL-1200 | 3500-4000kg/h | 90kw | 28-30cm |

We can make additional installations and modifications according to your requirements, and provide customization services free of charge.

What Are the Raw Materials in Wood Crusher Machine?

The raw materials in a wood crusher machine typically include various types of wood, such as logs, branches, timber scraps, and wood pallets.

Additionally, the machine can also process other biomass materials like bamboo, straw, agricultural residues, and even some types of non-wood materials.

Application of Wood Crusher Machine

The wood crusher machine is versatile and essential equipment in the forestry and woodworking industries.

- Wood Processing: The primary application of the wood crusher machine is in wood processing operations. These processed materials can be further used in various downstream processes like wood pellet production, wood-based panel manufacturing, and biofuel production.

- Biomass Fuel Production: By shredding and pulverizing biomass materials, the final products can be used as feedstock for biomass boilers, power plants, and other biomass energy systems. The produced biomass fuel, such as wood chips or sawdust, provides a renewable and sustainable energy source.

- Animal Bedding: Wood shredder machines are commonly used in the animal bedding industry. The machine can process wood and straw materials into fine particles, making them suitable as bedding material for livestock, poultry, and other animals.

- Composting and Mulching: It is also utilized in composting and mulching operations. It can be used as compost or mulch in gardening, landscaping, and agricultural applications.

Competitive Wood Crusher Machine Price

At our company, we take pride in offering our customers a wood crusher machine at a highly competitive price. We understand that affordability is essential to our customers, and we strive to provide the best value for their investment.

Our wood crusher machine price emphasizes quality, durability, and customer satisfaction, ensuring that the equipment you purchase from us delivers reliable performance, reduces maintenance costs ,and downtime over its lifespan.

If you need it, we encourage you to contact us to discuss your specific requirements and learn more about the attractive pricing and financing options we offer.

True Cases of Wood Crusher Machine Worldwide

When aiming to produce high-quality wood chips, relying solely on a hammer mill may prove inadequate.

In response to this challenge, numerous wood processing facilities worldwide have turned to our wood crusher machines, complemented by automatic conveying systems and dust removal mechanisms, to enhance their operational efficiency.

At our manufacturing facility, we recognize the unique needs of each customer. Hence, we offer a variety of sawdust processing plants tailored to accommodate diverse production demands.

Whether your operation requires a throughput of 500kg/h or up to 5t/h, we can devise a customized production plan tailored to your site requirements and budget constraints. Feel free to reach out to us for pricing details at your convenience.

Deep Processing of Wood

Large wood crushers can be used in shisha charcoal production lines, sawdust block production lines, charcoal production lines, and BBQ charcoal production lines.

Related Machine Recommendations

Wood Comprehensive Crusher | Wood Pallet Shredder

The wood comprehensive crusher, commonly known as a wood pallet…

Wood Hammer Mill | Hammer Mill Shredder

The wood hammer mill adopts a hammer and screen system…

Wood Shavings Machine | Log Shavings for Animal Bedding

The wood shaving machine can efficiently cut logs, branches, and…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chippers are designed to handle a wide range…

Wood Pallet Block Making Machine

The wood pallet block making machine, also known as a…

Wood Debarking Machine | Log Peeling Machine

Wood debarking machine, also known as a log peeling machine,…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for sale. You…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…

Shisha Charcoal Packing Machine

Our shisha charcoal packing machine is an important…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Charcoal Briquettes Packing Machine for Barbecue Charcoal

Our charcoal briquettes packing machine, namely BBQ charcoal…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…

Rice Husk Drying Machine | Rotary Dryer for Sale

Our rice husk drying machine, or a rotary…