Sawdust briquette making machine for sale to Algeria

A recent client from Algeria, involved in the renewable energy and biofuel industry, approached us with the goal of increasing local production of sustainable fuel through biomass briquettes.

With high demand for renewable fuel sources in Algeria, this client was particularly interested in converting various agricultural and forestry residues into briquettes.

They were looking for a machine capable of handling a variety of feedstocks, including sawdust, wood chips, rice husks, and other biomass waste such as bamboo scraps and bagasse.

Sawdust briquette making machine selection

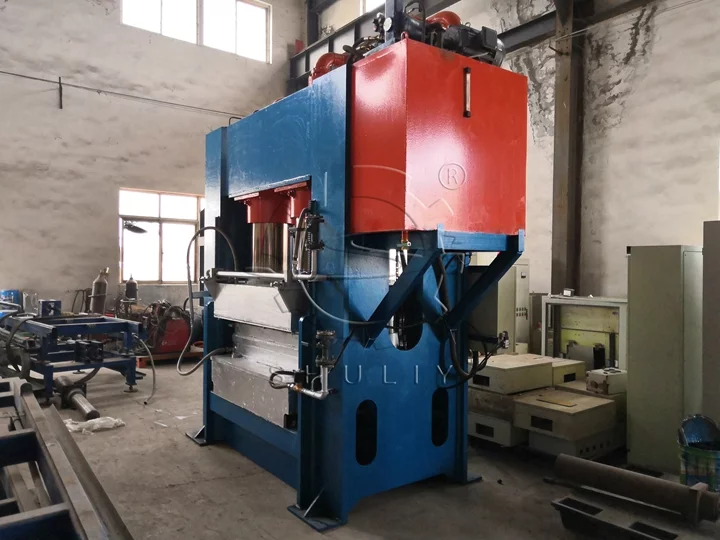

Based on the client’s requirements, we recommended our sawdust briquette making machine as an ideal solution due to its versatility, efficiency, and sustainable processing capabilities.

This machine is designed to convert a wide range of biomass materials into valuable briquettes, making it ideal for clients looking to utilize diverse biomass sources and agricultural residues.

The machine can process agricultural residues like rice husks, corn stalks, and coconut shells, as well as biomass waste such as forestry trimmings, sawmilling residues, and peanut shells. Its ability to process various materials aligns with the client’s goal of converting local waste products into a reliable fuel source.

Working principle and customization

During our discussions, we provided a detailed overview of the working principle of the machine, which operates efficiently through the following process:

- Crushing and drying. Raw materials are finely crushed to a particle size below 6mm, with a moisture content between 8% and 12%. Materials that are too large or wet would hinder briquette formation and increase machine wear. We advised the client to ensure raw materials are properly prepared to optimize machine performance.

- Heating and compression. After pre-processing, the heating ring raises the forming cylinder’s temperature to between 280-300°C. This high-temperature environment, combined with the screw propeller’s compressive action, allows the materials to be extruded smoothly from the mold into high-density, uniform wood briquettes.

Our client was impressed with the machine’s simplicity and efficiency, as it allows them to produce a high-quality product without the need for binders or additional additives.

We also customized specific settings to meet local standards in Algeria and adapted the machine to work optimally with available feedstocks.

Transaction details and logistics

During the negotiation process, we discussed various concerns related to pricing, energy consumption, and capacity. To meet the client’s production and budget requirements, we offered a competitive package with tailored pricing and emphasized the long-term benefits of using our machine.

To ensure smooth operations, we included detailed after-sales support along with technician training to maximize machine performance.

Once the order was finalized, we coordinated with the client to arrange shipping and import clearance. Upon arrival in Algeria, our team provided installation guidance and onsite training to ensure their operators were confident in managing the machine.

Results and client feedback on sawdust briquette making machine

Since the installation, the client has reported positive results. They noted the machine’s high output, efficiency, and low operational cost as key advantages. The flexibility to use various feedstocks has allowed them to adapt to seasonal material availability, further enhancing their production capabilities.

With this machine, the client is now able to meet local demand for eco-friendly biomass briquettes, contributing to Algeria’s push for sustainable energy solutions.

Summary

Our collaboration with this Algerian client is a testament to the power of adaptable, sustainable machinery in driving the growth of biofuel production. We are excited to support them as they expand their production and meet the needs of their community for clean and renewable energy.