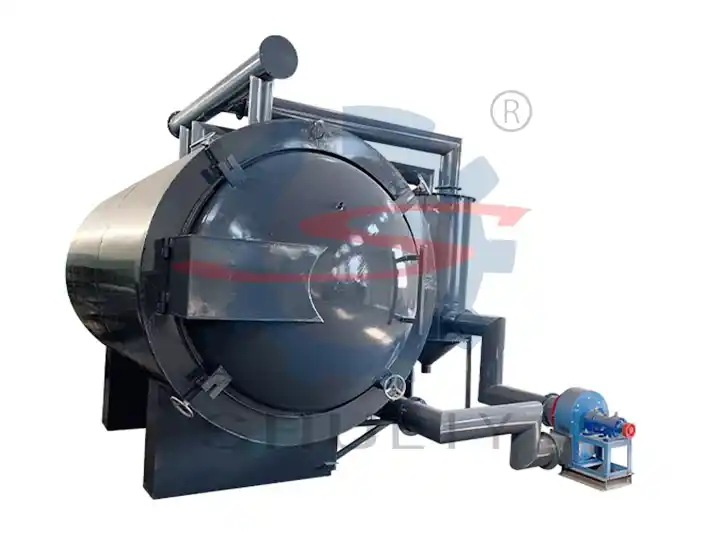

Horizontal Charcoal Furnace for Producing Biochar

Horizontal charcoal making machine | Log charcoal furnace

Horizontal Charcoal Furnace for Producing Biochar

Horizontal charcoal making machine | Log charcoal furnace

Features at a Glance

A horizontal charcoal furnace is a high-performance device designed for efficient and eco-friendly industrial carbonization. It features an innovative horizontal structure, integrating precise temperature control technology and an energy-saving combustion system. It can efficiently produce charcoal from wood, bamboo, sawdust, coconut shells, and other materials.

With a daily processing capacity of 900-3000 kg (12-14 hours per batch), it meets the needs of small to large-scale production. This furnace is widely used in biomass charcoal production, activated carbon manufacturing, metal heat treatment, and chemical raw material processing.

The horizontal carbonization furnace features a sealed, heat-resistant structure consisting of an outer shell, inner lining, pipelines, and a flue gas purification system. These components work together to ensure uniform and stable carbonization.

With an efficiency of over 95%, the furnace offers high thermal energy utilization, a short production cycle, and an excellent charcoal yield. Its stable performance, easy operation, low energy consumption, and high output make it highly popular among charcoal production enterprises.

Application of horizontal charcoal furnace

The horizontal charcoal furnace, also known as the log charcoal furnace or horizontal charcoal making machine, is a highly versatile and efficient carbonization solution.

Designed for industrial-scale production, it converts various biomass materials—such as wood chips, sawdust, and agricultural waste—into high-quality charcoal or biochar through a controlled carbonization process.

- Agriculture & forestry – Utilized for processing agricultural and forestry residues into biochar for soil improvement and carbon sequestration.

- Environmental protection – Helps reduce waste by converting biomass into eco-friendly charcoal, supporting sustainable energy solutions.

- Commercial charcoal production – Ideal for businesses requiring large-scale, high-efficiency carbonization to produce charcoal for fuel, activated carbon, or industrial applications.

Here are some photos showing the carbonization results of the products.

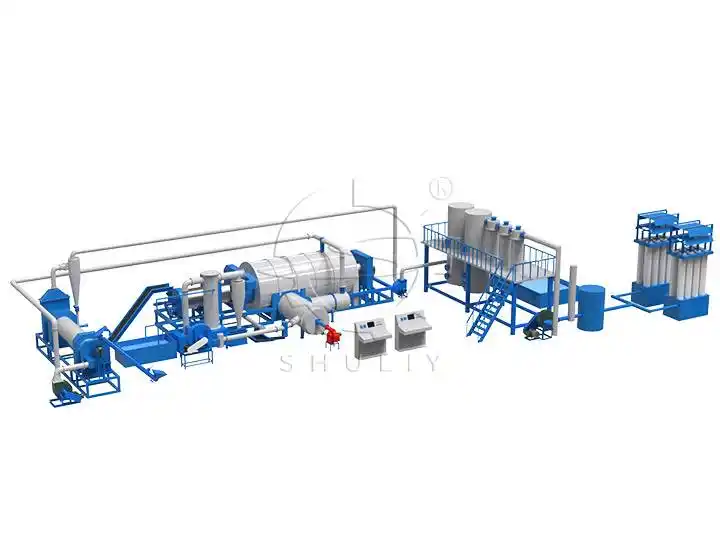

To meet diverse carbonization needs, we also offer continuous carbonization furnaces, vertical airflow carbonization furnaces, and other specialized models.

How does the horizontal charcoal making machine work?

- Biomass loading. Biomass materials are loaded into the horizontal charcoal furnace.

- Ignition and heat generation. The furnace is ignited, generating heat within the chamber and initiating the carbonization process.

- Temperature control. The temperature is generally controlled at about 600℃.

- Even heating. The horizontal layout ensures even heating of the biomass materials.

- Release of gases and volatiles. Evolved gases and volatile components are released during this phase.

- Controlled airflow. Controlled airflow is maintained within the horizontal furnace.

- Efficient removal. This ensures the efficient removal of moisture, volatile substances, and other impurities from the biomass materials.

- Gradual transformation. The materials undergo a gradual transformation, turning into high-quality charcoal.

Advantages of the horizontal design

- Optimal airflow. It also provides optimal airflow, which is crucial for the efficient removal of impurities and the production of high-quality charcoal.

- Uniform heat distribution. The horizontal design ensures uniform heat distribution throughout the carbonization process.

Carbonization process in log charcoal furnace

The carbonization process in a log charcoal furnace follows a structured sequence to ensure efficient and controlled charcoal production. By utilizing a well-designed system, the furnace effectively converts raw materials into high-quality charcoal through a cyclic combustion process.

- Loading the raw materials

- Log sections and branches are carefully arranged within an iron frame, which is then smoothly pushed into the furnace cavity using a conveyor track.

- Alternatively, coconut husks, broken branches, and other biomass materials can be directly loaded into the furnace barrel of the horizontal charcoal furnace.

- Sealing the furnace

- The cover of the airflow horizontal charcoal furnace is securely closed.

- Any gaps near the cover are sealed with mud or insulation cotton to prevent air leakage and ensure an airtight environment

Ignition and initial heating

- A gasification furnace is used to ignite the fuel in the ignition port at the bottom of the furnace.

- As the fuel burns, the temperature inside the furnace gradually increases.

Monitoring temperature and gas circulation

- The furnace thermometer is closely monitored. When the temperature reaches around 400°C, the gasification furnace is turned off.

- At this stage, the combustible gas produced inside the carbonization furnace undergoes cyclic combustion, reducing the need for external fuel.

Final carbonization and charcoal formation

- The carefully regulated heating process ensures effective transformation of raw materials into high-quality charcoal.

- The controlled airflow and heat distribution contribute to a consistent and efficient carbonization process

By following these systematic steps, the log charcoal furnace maximizes fuel efficiency, minimizes waste, and ensures high-output charcoal production, making it an ideal solution for commercial carbonization needs.

Structure of horizontal charcoal furnace

Enhanced thermal insulation

- Highly efficient thermal insulation rock surfaces are integrated into the furnace lid and body, ensuring superior heat retention.

- Advanced sealing design enhances thermal insulation, preventing heat loss during the carbonization process.

- Optimized furnace construction maintains stable internal temperatures, improving overall energy efficiency.

Efficient flue gas circulation

- A network of pipes is integrated into the furnace, connecting the upper and lower sections to optimize gas flow.

- Circulating pipes facilitate the movement of combustible gas within the cylinder, enhancing energy efficiency.

- Additional pipes are designed to filter flue gas, improving the furnace’s environmental performance.

Convenient trolley system

- Trolley systems are included to facilitate the transportation of raw materials and finished charcoal.

- Designed to handle the furnace’s substantial capacity and high output, ensuring smooth operation.

- Enhances overall efficiency and convenience, reducing labor intensity for operators.

Parameter of horizontal charcoal furnace

| Model | Capacity | Machine Weight | Dimensions (L×W×H) |

|---|---|---|---|

| SL-1300 | 900–1200 kg/12–14 hours | 2500 kg | 3×1.7×2.2 meters |

| SL-1500 | 1500–2000 kg/12–14 hours | 4000 kg | 4.5×1.9×2.3 meters |

| SL-1900 | 2500–3000 kg/12–14 hours | 5500 kg | 5×2.3×2.5 meters |

Horizontal charcoal making machine features

- Three-layer furnace body. The furnace body is constructed with three layers, and the door is lined with flame-retardant and heat-insulating cotton, ensuring excellent air tightness, heat retention, and energy efficiency while reducing fuel consumption.

- Flue gas recovery system. Integrated flue gas recovery technology enhances fuel efficiency, minimizing resource waste.

- Kiln car design. The movable kiln car simplifies operation, reducing labor intensity and making loading and unloading more convenient.

- High capacity & one-time carbonization. The machine accommodates large material loads, allowing for efficient batch carbonization.

- Multiple heating options. Compatible with various fuel sources, including wood, coal, and natural gas, providing flexibility based on availability and cost.

- Smoke-free emissions. A high-performance flue gas purification system ensures environmentally friendly operation with minimal smoke emissions.

- Water cooling system. A rapid cooling system accelerates the process, improving overall efficiency and productivity.

Contact us

If you’re interested in our product and would like to learn more details or request a quote, please don’t hesitate to contact us.

Our professional team is dedicated to providing you with support and assistance to help you achieve your charcoal production goals. Take action now and join us in shaping the future of sustainable charcoal production!

Hot Product

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Wood Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a…

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…

Sawdust Briquette Making Machine | Biomass Briquette Machine

The sawdust briquette making machine is an environmentally…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Coal Briquette Machine | Honeycomb Coal Press Machine

Coal briquette machine can produce different shape and…