Disc Wood Chipper | Wood Chips Making Machine

Wood chipping machine

Disc Wood Chipper | Wood Chips Making Machine

Wood chipping machine

Features at a Glance

Disc wood chippers are designed to handle a wide range of wood materials, including branches, logs, wood scraps, and other waste wood. They are particularly useful for processing wood waste from timber harvesting, tree pruning, and lumber production.

The resulting wood chips can be used for various purposes, such as mulching, composting, fuel, or as raw materials for the production of paper, particleboard, and biomass pellets.

Disc wood chips making machines are available in various sizes and capacities to suit different applications and production requirements. Shuliy offers 5 models of wood chippers, with an hourly output of 0.8–13 t, suitable for most wood processing businesses.

Our wood chippers produce high-quality chips, are durable, and affordable. They are popular in over 30 countries and regions, including Indonesia, Ghana, the UAE, Brazil, Russia, and France, etc.

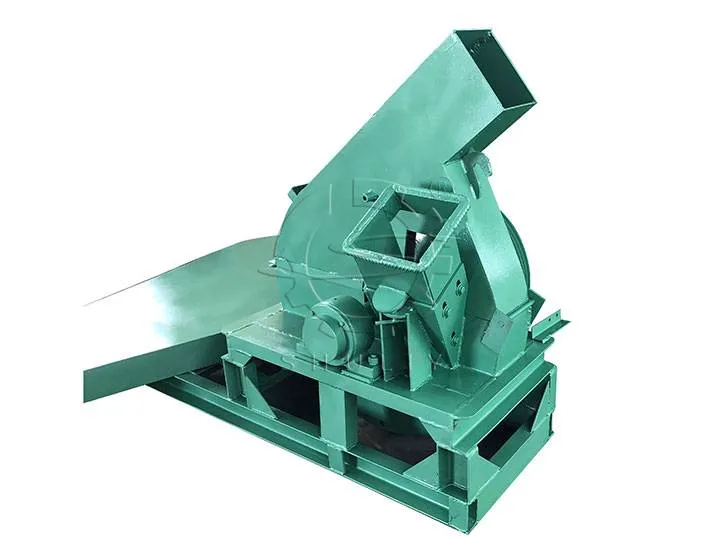

Disc Wood Chips Making Machine Structure

It consists of a rotating disc with sharp blades that cut and grind the wood materials fed into the machine. The disc wood chipper is widely used in various industries, including forestry, woodworking, paper making, and biomass power generation.

The wood materials are fed into the chipper through a hopper, and the rotating disc with blades rapidly cuts and grinds the wood into small chips or pieces. The size of the chips can be adjusted by changing the speed of the disc or adjusting the distance between the blades and the disc.

Technical Data of Electric Disc Wood Chipper

| Model | Power | Capacity | Number of blades | Input size | Weight |

| SL-400 | 7.5kw | 0.8-1.5t/h | 3pcs | 150*150mm | 160kg |

| SL-600 | 15kw | 1.5-2.5t/h | 3pcs | 180*150mm | 380kg |

| SL-800 | 22-30kw | 3-6t/h | 4pcs | 200*200mm | 550kg |

| SL-950 | 37-45kw | 5-8t/h | 4pcs | 230*250mm | 900kg |

| SL-1150 | 55-75kw | 8-13t/h | 4pcs | 300*330mm | 2400kg |

The above are standard models, we also offer customization.

Machine display

Commercial Wood Chipper for Sale

If you’re looking for a commercial wood chipper for sale, you’ll find different options available to meet your specific needs and requirements, including upper discharge and lower discharge.

Upper discharge

The mobile-friendly design of wood chippers with upper discharge is well-suited for small work. The processed wood chips can be directly deposited into storage equipment, such as a car bucket, streamlining the collection process.

Lower discharge

The wood chipping machine with lower discharge is typically larger and commonly used for continuous production in wood processing factories. This type of machine comes in both fixed and mobile versions.

Wood Chipper Disk Vs Drum Wood Chipper for Sale

The choice between a disk wood chipper and a drum wood chipper depends on the specific needs and requirements of the wood processing project.

Disk wood chippers are preferred for high-capacity and heavy-duty applications, while drum wood chippers are favoured for their versatility and ability to handle different wood materials effectively.

Disk Wood Chipper

- Design: Disk wood chippers have a horizontal rotating disk with blades attached to it. The wood is fed into the machine through a chute, and the rotating disk with blades chips the wood into smaller pieces.

- Advantages: Disk wood chippers are known for their high chipping capacity and fast processing speed. They are suitable for handling larger branches and logs, making them ideal for heavy-duty industrial applications.

- Applications: Disk wood chippers are commonly used in large-scale wood processing plants, forestry operations, and biomass power plants where a significant amount of wood needs to be chipped quickly.

Drum Wood Chipper

- Design: Drum wood chippers have a cylindrical drum with blades mounted on it. The wood is fed into the machine through a hopper, and the drum with blades chips the wood as it rotates.

- Advantages: Drum wood chippers are known for their consistent and uniform chipping performance. They are more versatile and can handle a wide range of wood materials, including branches, twigs, and small logs.

- Applications: Drum wood chippers are widely used in small to medium-sized wood processing facilities, landscaping, and agricultural applications. They are suitable for both commercial and residential use due to their ability to handle various wood sizes and types.

What You Will Get from Our Disc Wood Chipper?

When you choose our disc wood chipper, you can expect to get several benefits and advantages that will enhance your wood chipping experience.

High Chipping Efficiency

Our disc wood chipper delivers fast, efficient processing, turning large volumes of wood into valuable chips.

Versatile Use

It handles various wood materials, including branches, logs, and twigs, suitable for both hardwood and softwood.

Uniform Chip Size

Produces consistent wood chips, ideal for biomass fuel, landscaping, and animal bedding, ensuring better combustion and appearance.

Low Maintenance

Made with high-quality materials and precision engineering, reducing downtime and increases productivity.

Safe and Reliable

Equipped with emergency stop buttons and safety guards to protect operators.

Excellent Support

Professional customer service is available to answer questions and ensure user satisfaction.

Cooperate with Shuliy

Our disc wood chipper offers high efficiency, versatility, safety, durability, and excellent customer support. It is an ideal choice for your wood chipping needs, whether you are in the forestry industry, biomass production, or landscaping business.

In addition to our exceptional wood chipper machine, we also offer a range of other wood processing equipment. Feel free to inquire about our wood chipper as well as other devices, and discover comprehensive solutions for your wood processing needs.

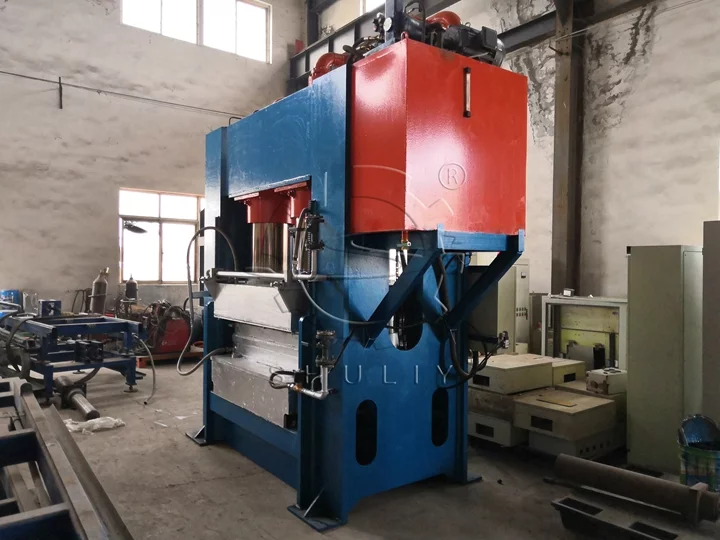

Wood Comprehensive Crusher | Wood Pallet Shredder

The wood comprehensive crusher, commonly known as a wood pallet…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process various wood…

Wood Hammer Mill | Hammer Mill Shredder

The wood hammer mill adopts a hammer and screen system…

Wood Shavings Machine | Log Shavings for Animal Bedding

The wood shaving machine can efficiently cut logs, branches, and…

Wood Pallet Block Making Machine

The wood pallet block making machine, also known as a…

Wood Debarking Machine | Log Peeling Machine

Wood debarking machine, also known as a log peeling machine,…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for sale. You…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution…

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Mesh Belt Dryer for Charcoal Briquette

The mesh belt dryer, also known as the…

Wood Hammer Mill | Hammer Mill Shredder

The Wood Hammer Mill efficiently crushes wood chips,…

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…