Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Hookah charcoal making machine | shisha charcoal press machine

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Hookah charcoal making machine | shisha charcoal press machine

Features at a Glance

Our popular Shisha Charcoal Machine can produce high-quality shisha charcoal briquettes. This versatile machine is ideal for crafting briquettes in various shapes, including round, cube, and other customized forms, to suit your specific requirements.

We offer three types of shisha charcoal press machines to cater to different needs: hydraulic, rotary round, and stainless steel models. Each model is built for efficiency and durability, ensuring exceptional performance.

By choosing our Shisha Charcoal Machine, you gain access to numerous benefits, including customization options and superior product quality. Contact us today to inquire about the machine’s price and discover how it can enhance your production process.

Popular application of shisha hookah

- Global popularity of shisha hookah. Shisha hookah, a traditional smoking method cherished across various cultures, is experiencing a surge in global demand.

- Key role of the shisha charcoal machine. This machine is essential for producing high-quality charcoal briquettes tailored specifically for shisha smoking.

- Meeting industry needs. As the shisha hookah market expands, the shisha charcoal machine provides businesses with a reliable solution for maintaining a steady supply of premium shisha charcoal.

- Supporting growth in the hookah industry. By ensuring efficient production, the machine helps businesses keep up with the rising demand for shisha products worldwide.

Final round or cube shisha from shisha charcoal making machine

- Ability to produce various shapes and sizes. The shisha charcoal machine can create a wide range of shisha charcoal briquettes to meet different preferences and market demands.

- Common shapes of shisha charcoal. These include cube, round, finger, and hexagonal shapes, all designed for easy ignition and even burning.

- Versatile dimensions of charcoal tablets. Popular sizes include diameters like 25mm, 28mm, 30mm, 33mm, 35mm, and more.

- Customization options for manufacturers. The machine allows businesses to tailor the shape and size of briquettes to specific requirements and market needs, making it an ideal solution for diverse product offerings.

Which Charcoal is Best for Hookah?

According to extensive feedback, the best charcoal for hookah is natural coconut shell charcoal, because it offers the following advantages:

- 100% natural and chemical-free: Made from coconut shells without harmful additives like nitrates or petroleum coke, making it healthier and safer.

- Long burning time: Typically burns for 60–90 minutes, suitable for extended smoking sessions.

- Stable heat output: Provides a steady and even heat source, avoiding temperature fluctuations and improving smoke quality.

- Odorless and smokeless: Does not interfere with the flavor of the shisha, delivering a cleaner and smoother experience.

- Low ash content: Produces very little ash (≤3%), making cleanup easier and keeping your hookah cleaner.

If you want to learn more details, please click the link below to read further. Which Charcoal is Best for Hookah?

Types of shisha charcoal machines

Hydraulic shisha charcoal press machine: Uses high hydraulic pressure to compress coconut shell charcoal powder into dense, stable, and hard hookah charcoal blocks.

Rotary tablet press machine: Designed for mass production of quick-light hookah charcoal tablets, producing continuous 33mm or 40mm round charcoal discs efficiently.

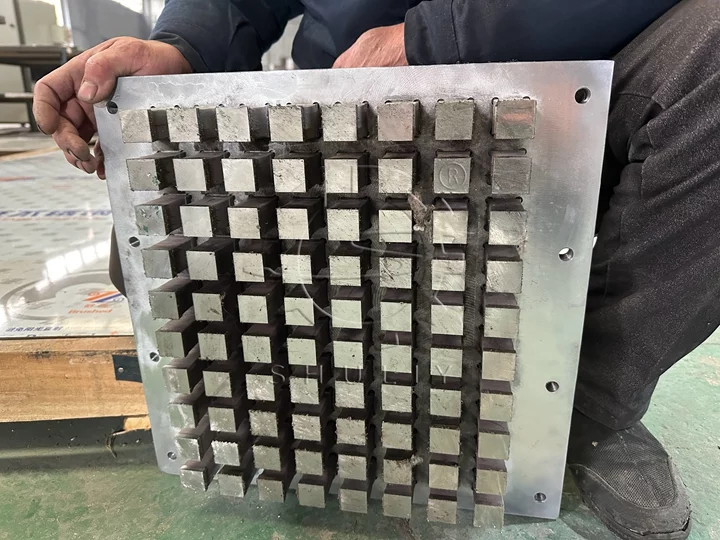

Stainless steel cube shisha charcoal machine: The stainless steel cube shisha charcoal machine is designed for producing high-quality, uniform cube-shaped charcoal tablets with excellent durability and corrosion resistance.

Type 1: hydraulic hookah charcoal press machine

The working principle of the hydraulic shisha charcoal press machine

Charcoal powder mixed with an appropriate amount of binder is fed into the mold cavity through a feeding system. Then, the hydraulic system applies high pressure to close and compress the upper and lower molds, compacting the loose charcoal powder into uniformly shaped charcoal blocks.

The formed charcoal blocks are automatically ejected from the mold and transported to the cooling area before packaging. This process uses hydraulic pressure to ensure the charcoal blocks have uniform density, high hardness, and stable, long-lasting combustion.

Features of the hydraulic hookah charcoal press machine

- Applies high hydraulic pressure for strong and dense charcoal block formation.

- Produces uniform, stable, and high-quality hookah charcoal blocks.

- Suitable for pressing various raw materials like coconut shell charcoal powder and fruitwood charcoal powder.

- Automatic mold release and efficient production process.

- Ensures consistent hardness and long-lasting burning performance.

- Easy to operate with high automation and reliability.

More component details display

Hydraulic hookah charcoal making machine parameter

| Item | SL-HS-1 | SL-HS-2 |

| Pressure | 60 tons | 80 tons |

| Weight | 2800kg | 2800kg |

| Hydraulic pump power | 15kw | 18.5kw |

| Main host dimension | 1000*2100*2000mm | 1000*2100*2000mm |

| Feeding power | 0.75kw | 0.75kw |

| Discharge power | 0.75kw | 0.75kw |

| Discharge conveyor | 800*850*1850mm | 800*850*1850mm |

| Control cabinet size | 530*900*1100mm | 530*900*1100mm |

| Capacity | 42 pieces per time, 4 times per minute(round shape)44 pieces per time, 4 times per minute(cubic shape) | 42 pieces per time, 3 times per minute(round shape)44 pieces per time, 3 times per minute(cubic shape) |

Type 2: rotary round shisha charcoal machine

The structural components of the rotary round shisha charcoal machine

The rotary round shisha charcoal machine consists of a rotating mold disc, a feeding system, a pressing unit, and a discharge mechanism, designed for efficient and continuous production of round charcoal tablets.

Uses of the rotary shisha charcoal press machine

- Suitable for pressing granular raw materials into various-shaped tablets

- Supports customization of multiple tablet shapes, including round, special-shaped, double-layer, and ring tablets

- Stable operation with low noise

- Provides high-pressure output to ensure pressing quality

- Equipped with an automatic overload shutdown to protect the machine from damage

Features

- Popularity in Arab countries. This machine has gained widespread recognition for its innovative features and high efficiency.

- Ability to compress mixed materials. It transforms well-mixed charcoal powder and coal dust into round charcoal briquettes with decorative letters or patterns.

- Variable frequency speed control allows for adjustable rotation speed.

- Can perform trial runs and adjustments without stopping the machine.

- All controllers and operating parts are reasonably arranged for easy operation.

- High pressure, smooth rotation, stable performance, safe and precise.

- Suitable for pressing various large tablets and hard-to-form tablets.

- Adjustable tablet diameters. The machine allows for easy customization of hookah charcoal diameters, ranging from 25mm to 35mm, with additional options available to meet specific customer requirements.

Rotary round shisha charcoal making machine specification

| Model | SL-ZPG |

| Pressure | 120KN |

| Power | 7.5kw |

| Weight | 1800kg |

| Filling depth | 55mm |

| Charcoal thickness | 20-28mm |

| Turntable speed | 17r/min |

| Dimension | 1100*840*2000mm |

| Capacity | 21,000 pieces per hour |

Type 3: stainless-steel cubic hookah charcoal making machine

The stainless steel cube shisha charcoal machine consists of a frame, a hydraulic system, molds, a feeding system, and a control system, designed specifically for producing high-density cube-shaped shisha charcoal blocks.

- Exceptional quality and performance. The stainless-steel cubic hookah charcoal making machine delivers outstanding results for shisha charcoal production.

- Durable stainless-steel construction. Built to resist corrosion and ensure long-lasting operation, it is ideal for heavy-duty use.

- Commonly processed sizes. The machine produces hookah charcoal in sizes such as 20*20*20mm (cubic), 25*25*25mm (cubic), 30mm (round), 33mm (round), 40mm (round), and more.

- Hygienic and reliable. Its stainless-steel design ensures durability, cleanliness, and resistance to corrosion, providing a dependable option for shisha charcoal manufacturers.

Advantages of shisha charcoal making machine

- Consistent quality. It guarantees uniform shaping and compression, ensuring reliable and high-quality hookah charcoal products.

- Environmentally friendly. Designed with eco-friendly materials and processes, it supports sustainable production and reduces environmental impact.

- Precise temperature control. The machine’s advanced temperature regulation system ensures even heat distribution, improving the quality and durability of the shisha charcoal.

- Long service life. Crafted from high-quality materials and precise engineering, the shisha charcoal machine is built for durability, reducing downtime and minimizing maintenance expenses.

- Customizable options. The machine can be customized to fit specific needs, offering flexibility in shapes, sizes, and production capacities.

- Increased profitability. By enhancing production efficiency, ensuring product consistency, and lowering labor costs, the shisha charcoal machine helps boost profitability for manufacturers.

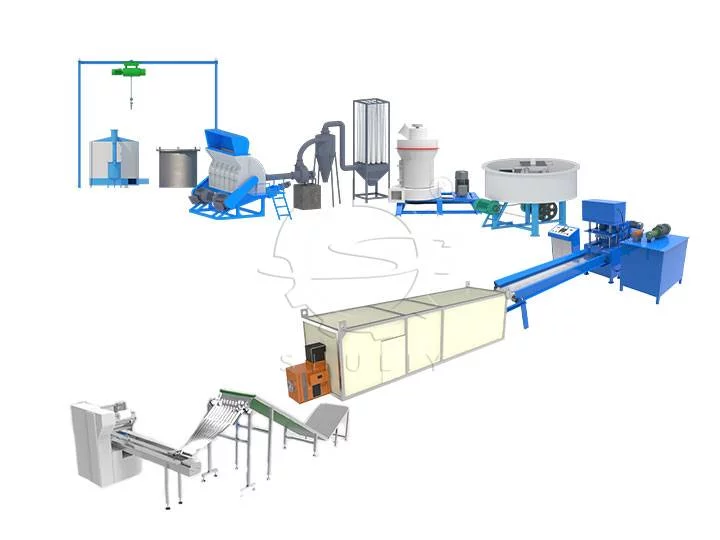

Supplementary machine for hookah charcoal machine

Charcoal briquettes packing machine

Our Hookah Charcoal Machine can be used with a dedicated Charcoal Briquettes Packing Machine, providing a comprehensive solution for your production line.

This packing machine efficiently packages the produced hookah charcoal briquettes, ensuring the cleanliness and easy transportation of the products. With seamless integration and user-friendly operation, it’s the ideal choice for boosting your production efficiency!

Shisha charcoal dryer

Shisha charcoal dryer, also called shisha charcoal drying room, is typically equipped with a fan, heating element, and temperature control system. Through hot air circulation, it quickly removes moisture from the charcoal blocks, improving drying efficiency and product quality. The drying temperature is adjustable to prevent overheating that could cause cracking or deformation, ensuring stable and durable finished products.

Why send an inquiry for shuliy shisha charcoal machine?

Sending an inquiry for the Shuliy shisha charcoal machine is beneficial because:

- Comprehensive information. Send an inquiry to receive detailed details about the machine’s specifications, features, and pricing, enabling you to make an informed decision based on your requirements.

- Personalized assistance. Shuliy’s customer support team is ready to offer personalized guidance, answer any questions, and provide tailored solutions to meet your specific needs.

- Discounts and special offers. We frequently provide competitive pricing and promotional deals to our customers, ensuring you get the best value for your investment without compromising on quality.

Conclusion

With its exceptional performance and versatile capabilities, this shisha charcoal press machine is designed to meet all your shisha charcoal production needs.

Contact us now to inquire about our shisha charcoal machine and explore the benefits it can bring to your business. Our team is ready to assist you with personalized solutions and competitive pricing.

Related Machine Recommendations

Charcoal Production Line Machine

The Charcoal Production Line Machine by our company offers a…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials, such as…

Charcoal briquette press machine exported to Iraq

Recently, our charcoal briquette press machine has successfully been sold…

Hookah charcoal making machine sent to Jakarta

As a leading supplier of hookah charcoal making machines, we…

Two vertical carbonization furnaces shipped to myanmar

Good news! Our vertical carbonization furnaces have been successfully shipped…

Which Charcoal is Best for Hookah?

Hookah (also known as Shisha), made using a hookah charcoal…

Hot Product

Wood Shavings Machine | Log Shavings for Animal Bedding

The Wood Shavings Machine efficiently cuts and processes…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…

Charcoal Briquettes Packing Machine for Barbecue Charcoal

Our charcoal briquettes packing machine, namely BBQ charcoal…

Drum Style Wood Chipper

A drum style wood chipper is used in…