Wood Hammer Mill | Hammer Mill Shredder

Wood hammer crusher

Wood Hammer Mill | Hammer Mill Shredder

Wood hammer crusher

Features at a Glance

The wood hammer mill adopts a hammer and screen system to efficiently crush wood chips, straw, waste paper, and coconut shells into uniformly sized sawdust and wood particles (3–8 mm).

Compared with traditional blade-type wood crushers, the hammer-type wood crusher is more versatile due to its hammering principle. It can handle a wider range of materials — including high-moisture, hard, or fibrous ones such as wood blocks, branches, bamboo, corn cobs, straw, and coconut shells. In contrast, conventional blade crushers are only suitable for dry materials like wooden boards, wood chips, and branches.

Shuliy offers seven models of wood hammer mill crushers, with capacities ranging from 800 kg/h to 5 tons/h, meeting the production needs of most wood processing factories.

Thanks to its durable quality and excellent crushing performance, Shuliy’s wood hammer mill has been well received by customers in many countries, including Brazil, Indonesia, Russia, Mexico, Tanzania, and the Arab region etc.

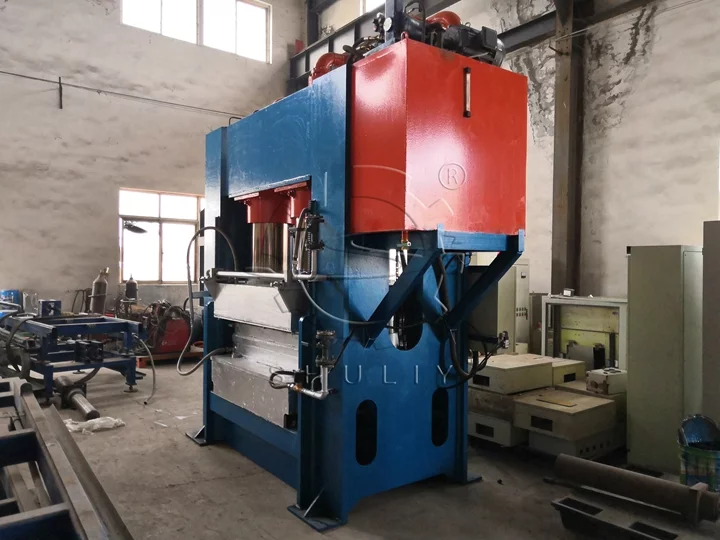

Hammer mill machine for sale from Shuliy

Shuliy’s wood hammer mill machine is distinguished by its versatility, high output capacity, precise particle size control, and robust construction. This machine offers a reliable and cost-effective solution for various processing applications with its energy efficiency, easy maintenance, and focus on safety.

Customers can also benefit from Shuliy’s excellent after-sales service and customization options, making it a trusted choice in the market for hammer mill machines.

Our state-of-the-art hammer mill machines are designed to meet all your wood processing needs. Next, let’s explore the various raw materials that these powerful machines can handle.

Raw material for hammer mill shredder

The hammer mill shredder can handle materials with high moisture content, hard texture, or strong fibers. It is capable of processing a wide range of raw materials—from wood and grains to charcoal and fibers—making it a highly sought-after machine for commercial applications.

- Wood materials: logs, wood chips, wood boards, branches, bamboo, poplar, fruit trees, and various other wood materials.

- Grains: It can effectively grind grains like corn, wheat, sorghum, buckwheat, soybeans, and more, making it valuable for feed mills and food processing industries.

- Charcoal: raw charcoal, bamboo charcoal, fruit charcoal, coconut shell charcoal, and other types of charcoal, contribute to the production of various charcoal-based products.

- Fibers: Rice straw, straw, wheat straw, cotton, hemp straw, and similar fibrous materials can be processed efficiently by the hammer mill shredder.

- Other materials: Apart from the above, the hammer mill can handle a diverse range of materials, such as cardboard boxes, coconut shells, Chinese herbal medicines, and forages, catering to different industries’ specific needs.

Now, let’s dive into the working principle of the wood hammer mill to see how these materials are processed.

Wood hammer mill working principle

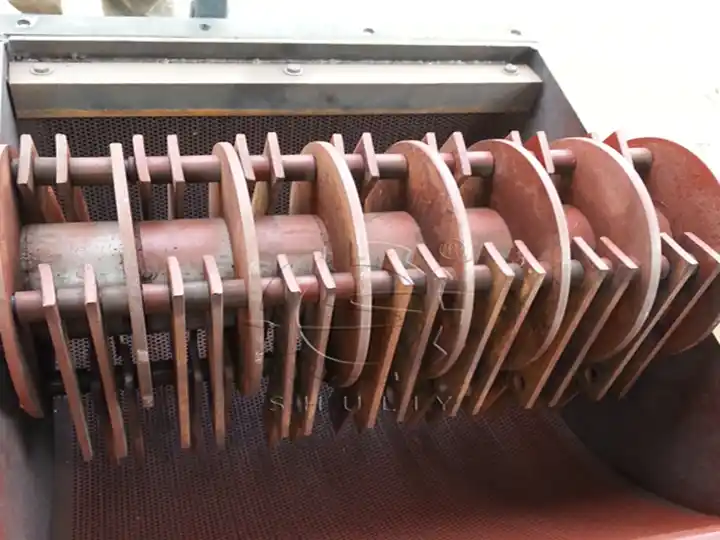

The wood hammer mill operates on a straightforward working principle based on impact and attrition. When the machine is in operation, the rotating hammers, typically made of high-strength steel, swing at high speed and strike the wood or other materials fed into the crushing chamber.

The wood or biomass materials enter the grinding chamber through the top feeding hopper. As the hammers rotate, they deliver powerful blows to the incoming materials, breaking them down into smaller pieces. The size of the final output particles is determined by the size of the holes in the screen or grate located at the bottom of the grinding chamber.

As the process continues, the smaller particles pass through the screen, while the larger particles remain inside the chamber for further grinding. The continuous rotation of the hammers and the presence of the screen ensure a controlled and consistent size reduction process.

The working principle of the wood hammer mill is both efficient and straightforward. Let’s take a closer look at the key advantages that set our wood hammer mill apart from the rest.

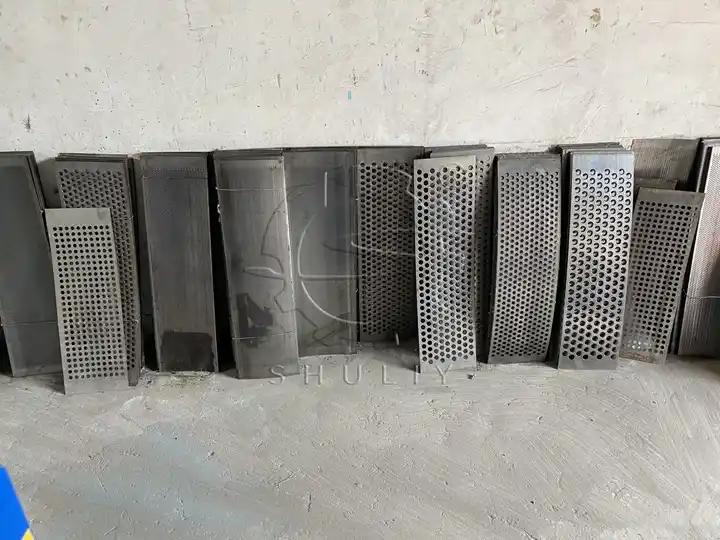

Structure of the wood hammer mill crusher

The hammer-type wood crusher mainly consists of the machine body, rotor system, hammers, screen, feed inlet, discharge outlet, and motor drive system. Its core is the high-speed rotating hammers, which impact, shear, and grind the material. The screen controls the particle size of the output, enabling efficient crushing of various raw materials such as wood, grains, charcoal, and fibers.

Material specifications

| Component | Material | Description |

|---|---|---|

| Body / Housing | Q235B Steel | Welded thick steel plate, strong and impact-resistant |

| Rotor Shaft | 40Cr Alloy Steel | High strength, withstands high-speed rotation impact |

| Hammer | Alloy Steel | Wear-resistant, impact-resistant, replaceable |

| Screen / Discharge Screen | High Carbon Steel | Controls discharge particle size, durable |

| Feed / Discharge Port | Q235B Steel | Durable, easy to connect with conveyor equipment |

| Transmission Belt / Coupling | Rubber Belt / High-strength Steel Coupling | Transfers power, absorbs shock |

| Motor | Standard Industrial Motor | Provides power, suitable for required capacity |

| Support Bearings | High-quality Rolling Bearings | Supports stable rotor operation |

Key advantages of wood hammer mill

Multi-Material Processing

The hammer mill efficiently processes a wide range of materials, not only wood but also straw, waste paper, and coconut shells, making it versatile for different production needs.

Adjustable Output Size

The machine allows users to control the particle size of the output, producing uniform sawdust or wood particles (3–8 mm), suitable for various applications.

Customizable Design

The crusher can be tailored to customer requirements, including feed inlet size, machine dimensions, and optional accessories such as wheels and dust removal systems, ensuring adaptability to different workshops and production layouts.

High-Efficiency Crushing Structure

- Core system features high-speed rotor and hammers, performing impact, shear, and grinding for efficient material reduction.

- Screens control particle size to ensure consistent output.

- High-capacity fans (7.5–22 kW) combined with cyclone separators enhance dust control.

Durable Material and Construction

- Hammers are made of high-hardness, wear-resistant materials for long service life.

- Sturdy machine body ensures stable, continuous operation even under high-intensity use.

Wide Range of Models and Capacity

Shuliy offers SL-HM60 to SL-HM1300, with capacities from 0.6 to 5 t/h, meeting the needs of small to large-scale wood processing plants.

Energy Saving

Advanced design optimizes energy consumption, maintaining high productivity while reducing operational costs.

Easy Operation and Maintenance

- Modular design allows easy assembly and maintenance.

- High-speed, high-output, low-energy operation while maintaining material integrity and uniform particle size improves overall production efficiency.

The unique features of our wood hammer mill provide numerous benefits for your operations. Moving forward, we’ll detail the specifications that make our hammer mill a standout choice.

Wood hammer mill specification

| Model | SL-HM60 | SL-HM70 | SL-HM80 | SL-HM90 | SL-HM1000 | SL-HM1300 |

| Power(kw) | 22 | 30 | 37 | 55 | 75 | 90 |

| Hammers(pcs) | 30 | 40 | 50 | 50 | 105 | 105 |

| Fan(kW) | / | / | 7.5 | 7.5 | 11 | 22 |

| Dust remover(pcs) | 5 | 5 | 5 | 5 | 14 | 14 |

| Cyclone diameter(m) | 1 | 1 | 1 | 1 | 1 | 1 |

| Capacity (t/h) | 0.6-0.8 | 1-1.2 | 1.2-1.5 | 1.5-3 | 3-4 | 4-5 |

Notes: The SL-HM60 and SL-HM70 are our top sellers because of their compact size and affordable price, while the SL-HM1300 is the most widely used model in large-scale production lines.

These specifications ensure our wood hammer mill meets your specific processing requirements. But how do you choose the right hammer mill shredder? Let’s explore that next.

Finished product in various sizes

How to choose the hammer mill shredder?

When choosing a wood hammer mill shredder, several key factors should be considered. First, determine the intended application and the type of materials you will be processing.

Next, consider the machine’s capacity and output requirements. Assess the volume of material you need to process daily and select a hammer mill shredder with a suitable capacity to meet your production demands. Additionally, pay attention to the machine’s power and motor specification.

Safety features are paramount when choosing a hammer mill shredder. Ensure that the machine is equipped with necessary safety mechanisms to protect operators and prevent accidents during operation. Safety interlocks, emergency stop buttons, and protective enclosures are examples of essential safety features to look for.

Finally, consider the after-sales support and service offered by the manufacturer. Choose a reputable supplier, such as Shuliy Machinery.

Selecting the right hammer mill shredder involves considering various factors. Finally, if you have any questions or need further information, don’t hesitate to contact us.

Wood hammer mill VS. wood crusher

| Item | Wood hammer mill | wood crusher |

|---|---|---|

| Working Principle | High-speed hammers impact and grind materials | Blades cut materials into wood chips |

| Applicable Materials | Wet, hard, and fibrous materials | Dry and uniform wood materials |

| Output Size | Fine and adjustable (about 3–8 mm) | Coarse (about 2–5 cm) |

| Energy Consumption | Slightly higher | Lower |

| Maintenance | Replace hammers and screen | Sharpen or replace blades |

| Adaptability | Strong, handles various materials | Weak, may clog with wet materials |

Summary: The wood hammer mill is more versatile and ideal for fine crushing of various materials, while the conventional wood crusher is better for cutting dry wood.

Applications of hammer-type wood crusher

- Wood pellet production – as the first step in biomass pellet manufacturing.

- Charcoal and briquette production – preparing fine wood powder for carbonization.

- Furniture and board factories – processing offcuts, panels, and waste wood.

- Agricultural waste recycling – crushing straw, rice husks, and corn stalks.

- Mushroom cultivation – preparing sawdust substrate for edible fungi.

Contact us!

Ready to take your wood processing to the next level? Our Hammer Mill Shredder offers unmatched efficiency and durability, making it the perfect choice for your industrial needs.

Don’t miss the opportunity to enhance your operations with our cutting-edge technology. Contact us now to request a quote and learn more about our products.

Additionally, we offer a range of other equipment, including small wood crushers and comprehensive crushers designed for wood waste and pallets. Let us help you find the perfect solution for your wood processing challenges!

Wood Comprehensive Crusher | Wood Pallet Shredder

The wood comprehensive crusher, commonly known as a wood pallet…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process various wood…

Wood Shavings Machine | Log Shavings for Animal Bedding

The wood shaving machine can efficiently cut logs, branches, and…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chippers are designed to handle a wide range…

Wood Pallet Block Making Machine

The wood pallet block making machine, also known as a…

Wood Debarking Machine | Log Peeling Machine

Wood debarking machine, also known as a log peeling machine,…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for sale. You…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine from Shuliy Machinery combines…

Wood crusher machine for business sent to Poland

We are pleased to present a successful case study involving…

Hot Product

Charcoal Mixer Machine | Charcoal Powder Mixer

This charcoal mixer machine can also be named…

Charcoal Crusher Machine | Charcoal Grinder Machine

This charcoal crusher machine can crusher woody raw…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Wood Comprehensive Crusher | Wood Pallet Shredder

The comprehensive crusher, commonly referred to as a…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Box Charcoal Briquettes Dryer Machine

This box charcoal briquettes dryer machine is an…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…

Wood Crusher Machine | Industrial Wood Shredder Machine

Wood crusher machines are designed to efficiently process…