Charcoal Production Line Machine

Charcoal Production Line Machine

Features at a Glance

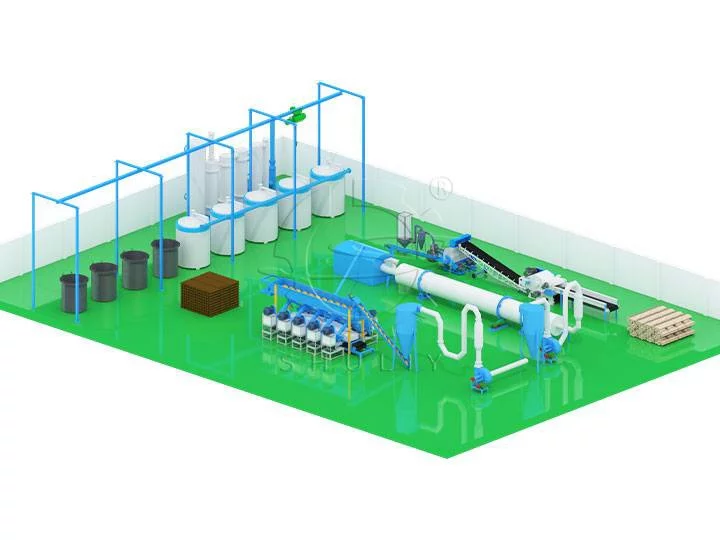

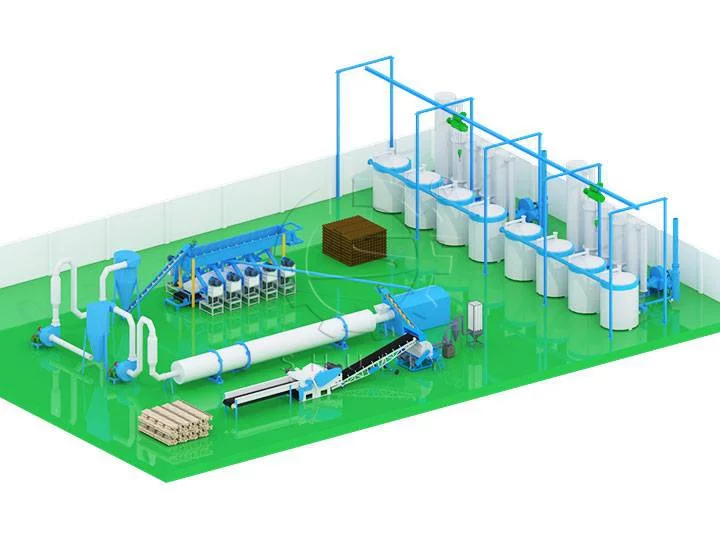

The Charcoal Production Line Machine by our company offers a comprehensive solution for transforming wood, wood chips, or other plant-based raw materials into high-density sawdust charcoal briquettes.

Our charcoal briquette production lines include processes such as crushing, mixing, molding, charring, and drying. We cater to various scales and processing needs. Configurations are available for 1-3t/d, 3-6t/d, and 6-10t/d output capacities.

Each line is equipped with essential machinery such as wood shredders, hammer mills, dryers, sawdust briquette machines, and carbonization furnaces. This charcoal making units ensure efficient production from raw material preparation to the final charcoal product.

As experts in biomass charcoal machines, we specialize in customizable equipment solutions that maximize efficiency. Our reliable charcoal products are suitable for diverse applications.

Raw materials for the charcoal production line

Understanding the raw materials needed for the charcoal production line is the first step to successful operation.

A charcoal briquette production line utilizes diverse raw materials, commonly including wood logs, bamboo, biomass, agricultural residues, and coconut shells. Each biomass type offers unique characteristics and considerations.

The choice of biomass for charcoal production depends on factors such as local availability, market demand, and specific product requirements for your processing plant.

Next, let’s delve into the working process of the charcoal briquette production line and understand the specifics of each step.

Charcoal production line working process

The technology of a charcoal production line systematically transforms raw materials into high-quality charcoal. It involves crushing, drying, briquetting, and carbonization processes.

Firstly, raw materials are crushed to increase their surface area for better carbonization. Then, moisture content is reduced through drying to ensure efficient charcoal conversion.

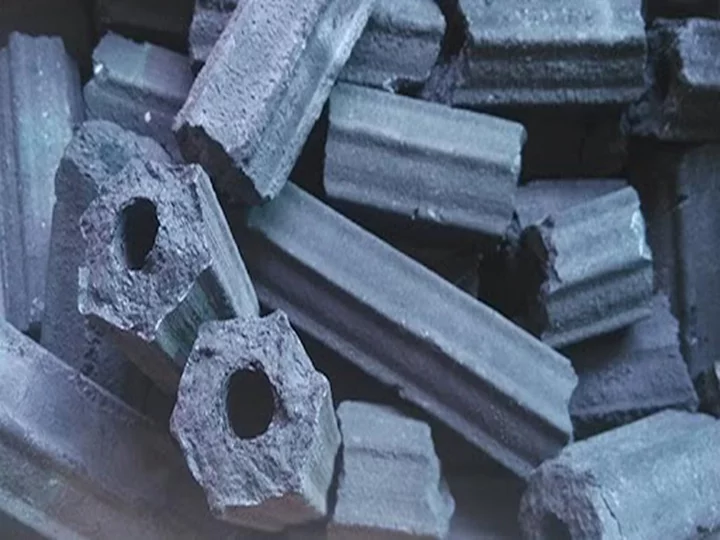

Next, materials are compacted through briquetting to form uniform briquettes, making them easier to handle and store.

Finally, carbonization occurs, turning the briquettes into hard charcoal with a longer burning time.

Charcoal production line machine for sale

After understanding the production process, you might be interested in the necessary equipment. We offer a variety of machines to suit different needs.

The wood shredder is used to crush raw materials, such as logs or branches, into smaller particles.

- Efficient and uniform shredding, ensuring consistent material size for optimal carbonization.

- High-speed operation, saving time and increasing production efficiency.

- Versatility to handle various types of wood and biomass materials.

The sawdust dryer is responsible for reducing the moisture content of the raw materials.

- Rapid and uniform drying, ensuring the raw materials are suitable for briquetting and carbonization.

- Energy-efficient operation, reducing production costs.

- Adjustable temperature and drying time for precise control of moisture content.

The biomass briquette machine is used to compress the dried raw materials into briquettes of desired shapes.

- Consistent and uniform briquette production, ensuring product quality.

- High pressure and density during briquetting, result in compact and durable briquettes.

- Versatility to work with various biomass materials, offering flexibility in product options.

The carbonization furnace is the final stage where the briquettes are converted into charcoal through the carbonization process.

- Controlled heating and oxygen deprivation for optimal carbonization.

- High-temperature insulation, ensuring efficient and thorough carbonization.

- Safety features and emission control mechanisms to adhere to environmental standards.

Advantages of the charcoal briquette production line

Having the right equipment is just the beginning. Learning about the advantages of the charcoal production line will help you make an informed investment decision.

- Efficiency. The charcoal production line integrates multiple processes for continuous and efficient charcoal production.

- Versatility. It handles various raw materials like wood, sawdust, and biomass, offering production flexibility.

- Quality Control. Ensures consistent product quality from crushing to carbonization, yielding high-quality charcoal.

- Environmental Considerations. The carbonization furnace includes emission control mechanisms to meet environmental regulations.

- Profitability. Converts low-cost raw materials into valuable charcoal products, offering a profitable investment opportunity.

With these advantages in mind, we will guide you on how to set up an efficient charcoal processing plant.

How to set up a charcoal processing plant?

Setting up a charcoal processing plant requires thorough planning. Start with market research and a business plan to understand demand and competition. Choose a location near raw materials and transportation, considering environmental regulations. Invest in essential equipment like shredders, dryers, carbonization furnaces, and packaging machinery.

Ensure a steady supply of raw materials and maintain equipment regularly. Comply with local regulations for efficient and sustainable operations. Develop a marketing strategy and establish distribution channels. Train staff on equipment operation, quality control, and safety for a skilled and efficient workforce.

Once the plant is established, understanding the applications of charcoal products will help you expand your market and sales channels.

Charcoal production line application

Industrial manufacturing. Used by industries requiring charcoal for processes such as metallurgy, chemical production, and energy generation.

Agriculture and forestry. Utilized by farmers and forestry operations to convert agricultural waste, wood residues, and biomass into charcoal for sale or personal use.

Commercial use. Employed by commercial enterprises, such as charcoal production plants and manufacturers, to produce charcoal products for retail and wholesale distribution.

Environmental solutions. Adopted by environmental organizations and initiatives focused on sustainable practices and waste management, using biomass waste for charcoal production to reduce environmental impact.

Energy sector. Applied in the energy sector for producing charcoal as a renewable energy source, contributing to energy independence and reducing reliance on fossil fuels.

Research and development. Utilized in research institutions and universities for studying charcoal production techniques, carbonization processes, and exploring new applications for charcoal.

Shuliy service for charcoal making production line

To ensure the smooth operation of your charcoal production line, Shuliy offers comprehensive services and support.

Shuliy Machinery offers high-quality machines and comprehensive services to support charcoal briquette production line owners. Our technical support includes personalized consultations and troubleshooting assistance, ensuring efficient setup and operation.

We provide thorough operator training programs to equip your team with essential skills for safe and productive use of our equipment. Additionally, our reliable after-sales maintenance ensures minimal downtime and extends the longevity of your charcoal making production line, supporting long-term success and profitability.

Leave your message!

Whether you are looking to enhance existing production capabilities or achieve significant efficiency gains through technological upgrades, our Charcoal Making Production Line offers tailored solutions for your needs.

Our equipment efficiently processes various raw materials such as wood and plant residues into high-quality charcoal, ensuring production stability and sustainability with advanced control technology and reliable design.

Contact our expert team now to discover how integrating this advanced equipment can optimize your production processes, delivering substantial benefits and competitive advantages for your business!

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials, such as…

Shisha Charcoal Machine for Round & Cube Hookah Charcoal

Our popular Shisha Charcoal Machine can produce high-quality shisha charcoal…

Charcoal briquette press machine exported to Iraq

Recently, our charcoal briquette press machine has successfully been sold…

Hookah charcoal making machine sent to Jakarta

As a leading supplier of hookah charcoal making machines, we…

Two vertical carbonization furnaces shipped to myanmar

Good news! Our vertical carbonization furnaces have been successfully shipped…

Hot Product

Vertical Carbonization Furnace for Hardwood Charcoal Making

This vertical carbonization furnace can be used for…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Heat Shrink Film Packaging Machine | Charcoal Briquette Packing Machine

Our heat shrink film packaging machine, also known…

Coal Briquette Machine | Honeycomb Coal Press Machine

Coal briquette machine can produce different shape and…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

The Continuous Carbonization Furnace is for the large-scale…

Wood Pallet Block Making Machine

Wood pallet block making machine utilizes sawdust and…

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…