Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

Biomass carbonization furnace

Continuous Carbonization Furnace | Sawdust Charcoal Making Machine

Biomass carbonization furnace

Features at a Glance

The Continuous Carbonization Furnace is designed for the large-scale production of high-quality charcoal from various biomass materials, including rice husks, coconut shells, wood chips, sawdust, and other similar materials.

With a capacity of 400-2000kg/h, it operates under high-temperature conditions to achieve oxygen-free, dry distillation, resulting in a high carbonization rate for materials like straw, palm kernel shells, and bamboo scraps.

This makes the Continuous Carbonization Furnace an ideal solution for businesses looking to produce sustainable charcoal efficiently.

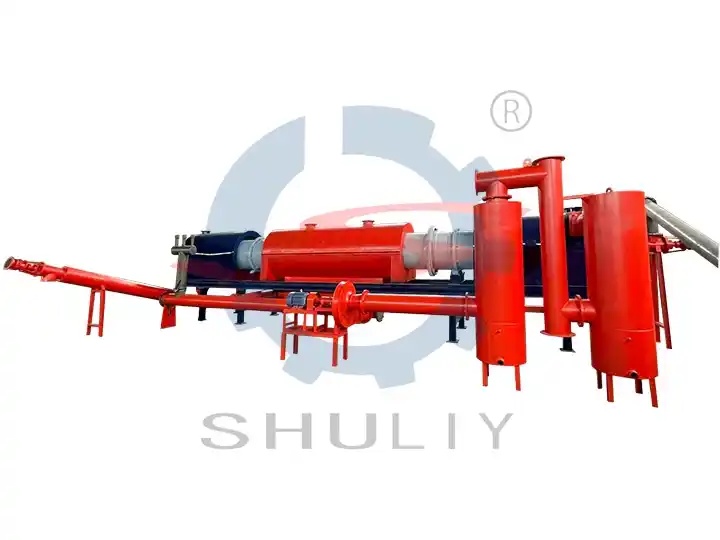

Continuous carbonization furnace for sale

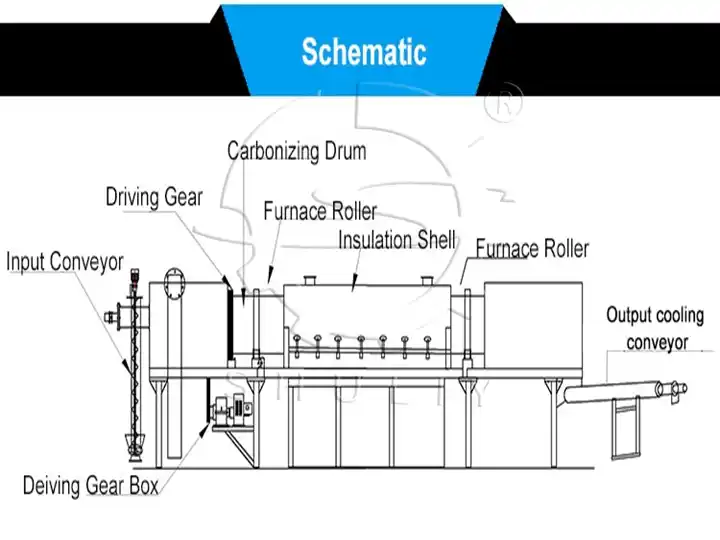

The continuous carbonization furnace consists of a screw feeding system, horizontal feeding, rotary drum, condensation discharge, burner, combustion chamber, purification unit, and control cabinet.

Schematic of the continuous carbonization furnace

Core components showcase

- Carbonizers. The core unit for converting biomass into charcoal.

- Gasifiers. Facilitate the production of combustible gases during the carbonization process.

- Soot processors. Filter out impurities and prevent the emission of harmful particles.

- Combustible gas purifiers. Remove contaminants from the gases to ensure clean emissions.

- Combustible gas condensers. Collect and condense the gases for further use.

- Induced draft fans. Promote gas circulation throughout the system to maintain efficient operation.

The continuous carbonization furnace is composed of several key components that work in synergy to produce high-quality charcoal while minimizing environmental impact.

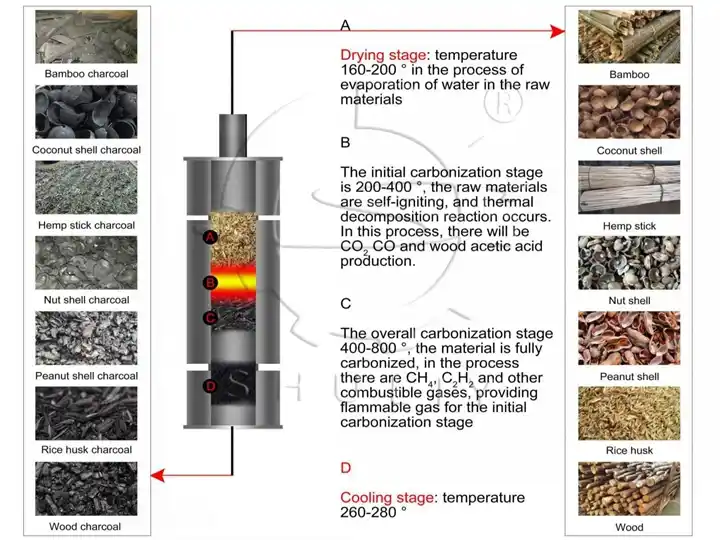

Production process of the continuous carbonization furnace

The Continuous Carbonization Furnace operates by harnessing the heat generated from the combustion process to initiate the pyrolysis of biomass feedstock.

As the material moves through the rotating drum, it is subjected to carefully controlled high temperatures, which break down complex organic compounds and release volatile gases.

These gases are then burned in the combustion chamber, significantly improving the furnace’s energy efficiency while minimizing harmful emissions.

- Heat utilization. Uses combustion heat to initiate pyrolysis of biomass feedstock.

- Rotating drum. Biomass moves through the drum, ensuring even exposure to high temperatures.

- Efficient breakdown. High temperatures decompose organic compounds and release volatile gases.

- Energy maximization. Volatile gases are burned in the combustion chamber for optimal energy use.

- Emission reduction. The wood tar and wood vinegar generated during the production process are combusted, ensuring no environmental pollution. Water is recyclable, helping to save and conserve water resources.

Specification of continuous carbonization furnace

Hot-selling continuous carbonization furnace:

| Model | SL-CF800 | SL-CF1000 | SL-CF1200 |

| Diameter(mm) | 800 | 1000 | 1200 |

| Capacity(kg/h) | 400-600 | 800-1000 | 1200-2000 |

| Main Power(kw) | 18.5 | 18.5 | 20 |

| Carbonization Temperature(℃) | 500-800 | 500-800 | 500-800 |

| Fan Power(kw) | 5.5 | 5.5 | 5.5 |

We support customization services. If you would like to learn more about our models and product details, please feel free to contact us!

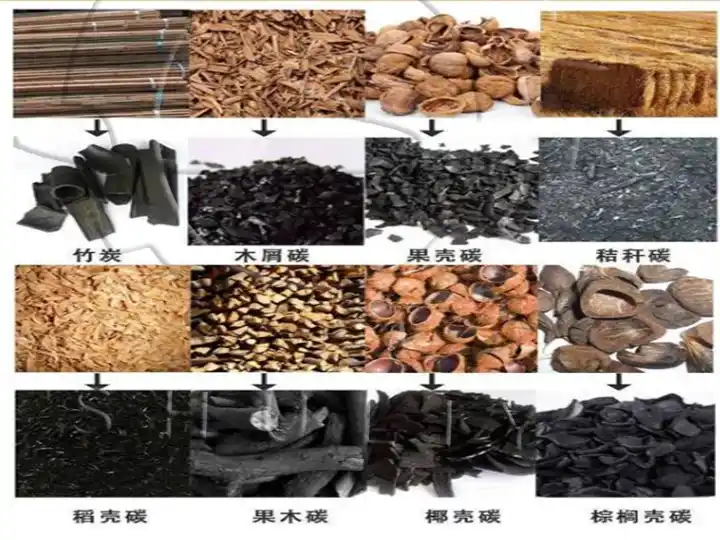

What materials are suitable for sawdust charcoal making machine?

The sawdust charcoal making machine is capable of processing a wide variety of raw materials, making it highly versatile.

It can handle biomass, sludge, garbage, and other materials, as long as their size is below 15 cm and moisture content is under 15%.

These materials can be directly carbonized, enabling efficient and sustainable production of charcoal.

- Biomass materials (e.g., sawdust, peanut shells, corn stalks, and rice husks)

- Agricultural residues (e.g., bagasse, sorghum stalks, and cotton stalks)

- Forestry waste (e.g., bamboo chips, branches, and palm shells)

- Other organic waste (e.g., distiller’s grains, corncobs, and dead leaves)

- By-products from various industries (e.g., coffee grounds, apricot husks, and traditional Chinese medicine residue)

- Various plant stalks (e.g., sunflower seed husks, yam grass, and hemp stalks)

These materials can all be efficiently processed in the continuous carbonization furnace to produce high-quality charcoal.

Advantages of continuous carbonization furnace

- High efficiency. Enables continuous operation, boosting productivity by eliminating frequent loading and unloading.

- Consistent output. Ensures uniform carbonization, resulting in consistent quality of the final charcoal.

- Energy efficiency. Utilizes heat recovery systems to recycle flue gas and waste heat, reducing energy consumption.

- Flexibility. Adapts to various raw materials and carbonization settings, such as temperature, residence time, and gas flow rate.

- Automated control. Features advanced automation for precise monitoring, enhancing safety and minimizing human intervention.

- Environmental friendliness. Incorporates dust removal and emission control systems to meet environmental standards and reduce pollution.

- Cost savings. Reduces labor and energy costs, while its high-quality output improves market competitiveness and profitability.

Technology feature of continuous carbonization furnace

- High automation. Assembly line production with advanced technology for high-temperature sealing, allowing carbonization in various environments (vacuum, positive pressure, atmosphere protection, oxygen-free).

- Adjustable temperature range. Temperature can be precisely controlled from 50-1000°C to meet specific product requirements.

- Normal pressure operation. Ensures superior operating conditions with minimal dust in the workshop.

- Low air volume. Reduces the pressure on the dust collection system by requiring minimal air volume.

- Controlled firing time. Firing time can be adjusted to ensure even and thorough carbonization.

- Energy recycling. Comprehensive thermal energy recycling enhances thermal energy utilization efficiency.

- Multiple temperature zones. Inner cylinder can have multiple zones for temperature control based on product characteristics.

- Solvent recovery. Convenient for the recovery of solvents from materials.

- High filling material rate. Achieves over 15% filling material rate for optimal heat exchange with hot flue gas, with a maximum rate of 25%.

How does the sawdust charcoal making machine work?

- Deflector mechanism. Raw material enters the carbonization main furnace and moves horizontally with the rotation of the furnace, guided by the deflector.

- Continuous carbonization. The material gradually moves from the feed inlet to the carbon outlet while undergoing carbonization during its movement.

- Air locks. Both the feed and carbon outlets are equipped with air locks to prevent air from entering, maintaining an oxygen-poor environment.

- Induced draft fan. The main furnace is equipped with an induced draft fan to maintain the oxygen-poor atmosphere during the continuous feeding and carbonization process.

- Continuous operation. The design allows for continuous feeding and carbonization, enhancing efficiency and production capacity.

- Improved carbonization results. The oxygen-poor environment ensures better carbonization quality and is ideal for producing charcoal and bamboo charcoal.

Customer cases in continuous carbonization furnace

In a remarkable success story, a customer from Congo placed an order for a continuous carbonization furnace and charcoal grinder from Shuliy Factory.

With an impressive output capacity of 800-1000kg/h, these machines were specifically chosen to facilitate the production and sale of high-quality barbecue charcoal.

Contact us

In conclusion, the Continuous Carbonization Furnace stands as a beacon of innovation in the realm of sustainable charcoal production. Its continuous process, efficient biomass conversion, and eco-friendly operation make it an indispensable asset for industries seeking greener practices.

Additionally, we’re proud to offer two other models of carbonization furnaces: the Hoist Carbonization Furnace and the Horizontal Carbonization Furnace.

Each model offers unique features to cater to diverse needs in charcoal production and sustainable energy solutions. Explore our range of carbonization furnaces and revolutionize your approach to charcoal production today.

SL-CF1200 Continuous Carbonization Furnace Successfully Shipped to the UK

In March 2025, a UK-based company focused on nature restoration…

Hot Product

Compressed Wood Pallet Machine for Presswood Pallet

Our compressed wood pallet machine is designed to…

Drum Style Wood Chipper

A drum style wood chipper is used in…

Portable Wood Saw Mill Machine | Timber Sawing Machine

The portable wood saw mill machine has great…

BBQ Charcoal Making Machine | Coal Ball Press Machine

BBQ Charcoal Making Machine can press powdery materials,…

Wood Debarking Machine | Log Peeling Machine

Wood Debarking Machine, also known as a Log…

Animal Feed Pellet Machine | Pellet Feed Mill Machine

Shuliy offers the animal feed pellet machine for…

Horizontal Charcoal Furnace for Producing Biochar

The Horizontal Charcoal Furnace is a high-performance equipment…

Disc Wood Chipper | Wood Chips Making Machine

Disc wood chipper stands as a versatile solution…

Charcoal Briquette Machine | Charcoal Extruder Machine

The charcoal briquette machine, also known as the…